- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 04, 2025 10:44

Back to list

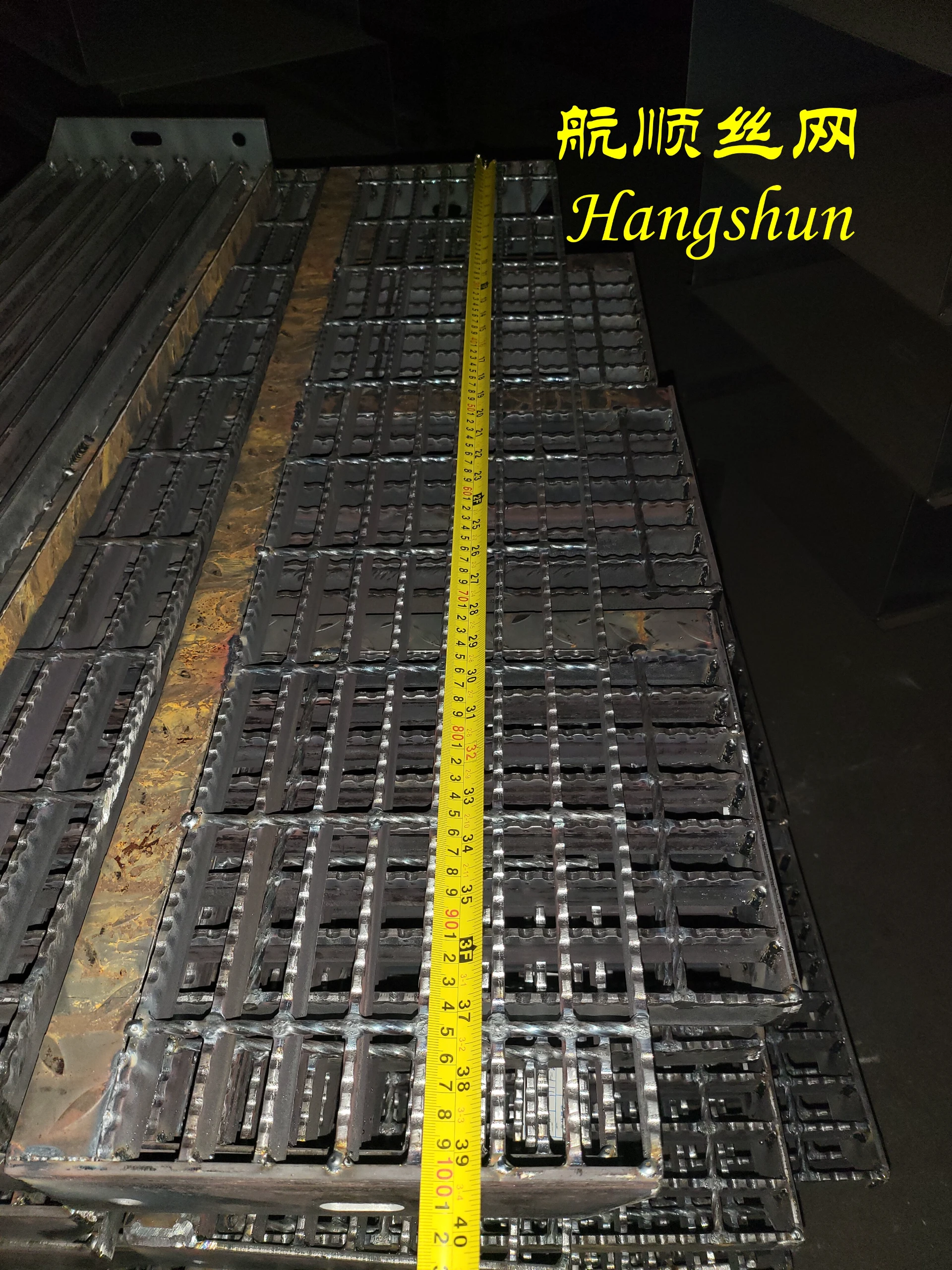

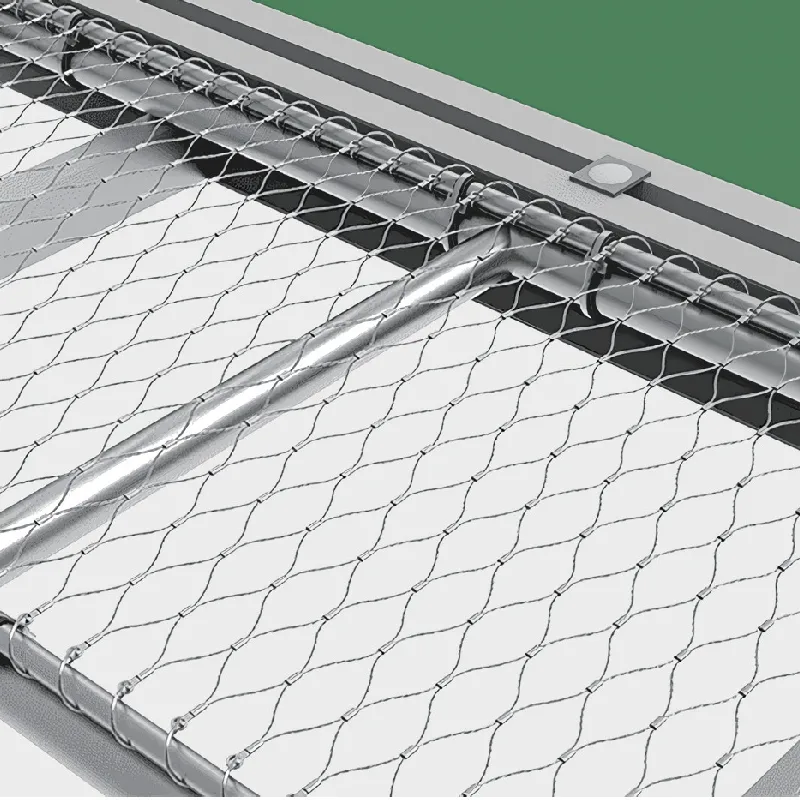

Swage-Locked Steel Grating

Carbon steel grating, often utilized in industrial flooring applications, stands out as a robust and versatile material that balances strength and cost-effectiveness. This type of grating is commonly chosen for its durability in demanding environments, making it essential for platforms, walkways, and other infrastructures where safety and reliability are paramount.

From the standpoint of authority in the industry, it's notable that carbon steel grating complies with various national and international standards, making it a trusted choice. Standards such as ANSI/NAAMM MGB 531-00 and BS 4592-1 specify the product’s design, dimensions, and testing requirements. These guidelines ensure that when you choose a carbon steel grating, you invest in a quality and safe product, securing long-term value for your projects. Moreover, businesses across numerous industries have vouched for the effectiveness and reliability of carbon steel grating through decades of use. This widespread endorsement, backed by positive testimonials and case studies, bolsters its credibility further. Companies in sectors like oil and gas, mining, and transportation regularly report substantial advantages in safety and cost savings after incorporating carbon steel grating into their infrastructure solutions. In practice, maintaining the trustworthiness of a carbon steel grating system also involves regular inspection and maintenance. Routine checks for signs of corrosion, structural integrity, and fastener security are necessary to uphold safety standards. Engaging professional inspection services can be beneficial, as they bring specialized equipment and experience to detect issues that might not be apparent to the untrained eye. To encapsulate, carbon steel grating offers an amalgam of experience-derived reliability, specialized product attributes, industry-approved authority, and trustworthiness. For industries demanding both resilience and cost-effectiveness, choosing carbon steel grating is a decision grounded in reason and practicality. It represents a confluence of engineering excellence and operational efficiency, ensuring your projects stand the test of time while upholding the utmost standards of safety and functionality.

From the standpoint of authority in the industry, it's notable that carbon steel grating complies with various national and international standards, making it a trusted choice. Standards such as ANSI/NAAMM MGB 531-00 and BS 4592-1 specify the product’s design, dimensions, and testing requirements. These guidelines ensure that when you choose a carbon steel grating, you invest in a quality and safe product, securing long-term value for your projects. Moreover, businesses across numerous industries have vouched for the effectiveness and reliability of carbon steel grating through decades of use. This widespread endorsement, backed by positive testimonials and case studies, bolsters its credibility further. Companies in sectors like oil and gas, mining, and transportation regularly report substantial advantages in safety and cost savings after incorporating carbon steel grating into their infrastructure solutions. In practice, maintaining the trustworthiness of a carbon steel grating system also involves regular inspection and maintenance. Routine checks for signs of corrosion, structural integrity, and fastener security are necessary to uphold safety standards. Engaging professional inspection services can be beneficial, as they bring specialized equipment and experience to detect issues that might not be apparent to the untrained eye. To encapsulate, carbon steel grating offers an amalgam of experience-derived reliability, specialized product attributes, industry-approved authority, and trustworthiness. For industries demanding both resilience and cost-effectiveness, choosing carbon steel grating is a decision grounded in reason and practicality. It represents a confluence of engineering excellence and operational efficiency, ensuring your projects stand the test of time while upholding the utmost standards of safety and functionality.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024