- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

serrated flat bar

Understanding Serrated Flat Bars An Overview

Serrated flat bars are an essential component in various industrial applications, known for their unique design and functional benefits. These bars have serrated edges or surfaces that provide enhanced grip and stability, making them ideal for a wide range of uses. In this article, we will explore what serrated flat bars are, their construction, applications, advantages, and some considerations to keep in mind when selecting them for specific projects.

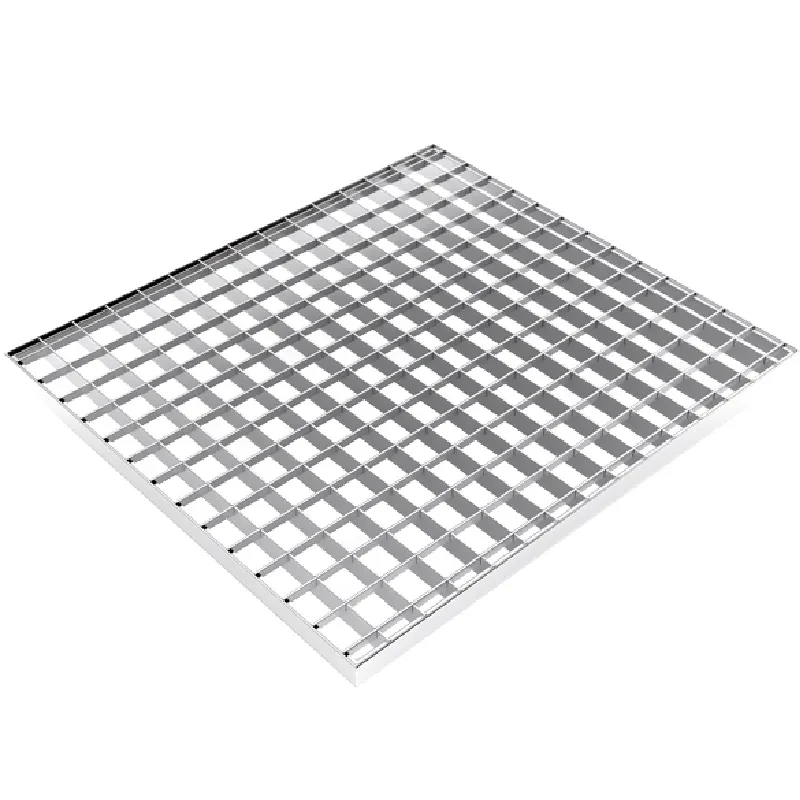

What are Serrated Flat Bars?

Serrated flat bars are elongated metal strips with one or more of their edges shaped into a serrated design. This serration process creates a series of notches or grooves that increase surface area, which in turn enhances friction. Typically made from materials such as stainless steel, carbon steel, or aluminum, these bars are utilized in various sectors, from construction to manufacturing.

Construction and Design

The construction of serrated flat bars involves a process where flat steel is cut, shaped, and then subjected to a serration technique. The serrations can vary in depth, angle, and spacing depending on the specific requirements of their intended use. The standard dimensions of these bars can also vary; they can be produced in a range of lengths and widths to meet the needs of different applications.

Applications of Serrated Flat Bars

1. Safety Platforms and Walkways In various industrial settings, serrated flat bars are commonly used to create anti-slip surfaces for walkways and platforms. Their gripping surface significantly reduces the risk of slips and falls, particularly in environments where water, oil, or other slippery substances may be present.

2. Support Structures These bars can also serve as effective support structures in scaffolding and framework systems. The serrated surface enhances the interlocking capability between components, providing additional stability and safety.

serrated flat bar

3. Machinery and Equipment Serrated flat bars are used in the construction of machinery where enhanced grip is necessary. For instance, they can be incorporated into the design of conveyor belts or feeding mechanisms, ensuring that materials do not slip during transportation.

4. Customization in Design Many industries benefit from the ability to customize serrated flat bars to meet specific performance criteria. This allows manufacturers to tailor the serration patterns, materials, and dimensions for specialized applications.

Advantages of Serrated Flat Bars

One of the primary benefits of serrated flat bars is their ability to provide better traction compared to smooth flat bars. This improved grip can lead to a decrease in accidents and injuries in workplaces. Additionally, serrated flat bars are highly durable and resistant to wear and tear, making them a cost-effective choice for long-term use.

Moreover, they are relatively lightweight, which can facilitate easier handling and installation. Their versatility across various applications means that businesses can utilize them in multiple projects without the need to switch materials.

Considerations for Selection

When choosing serrated flat bars for a specific application, several factors should be considered. The load-bearing capacity, environmental conditions, and required dimensions are critical aspects. For example, if the bars are to be used in corrosive environments, opting for stainless steel may be beneficial. Additionally, the specific design of the serrations should align with the intended use to ensure optimal performance.

Conclusion

In conclusion, serrated flat bars are invaluable tools in numerous industrial applications, providing enhanced grip and safety. Their ability to be customized and their inherent durability make them a popular choice among engineers and manufacturers. By understanding their features and applications, businesses can make informed decisions that enhance performance and safety across a variety of settings. Whether it is for constructing safety platforms, supporting machinery, or any other use, serrated flat bars are a reliable solution worth considering.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024