- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

metal grating price

The Economics of Metal Grating Understanding Prices and Market Dynamics

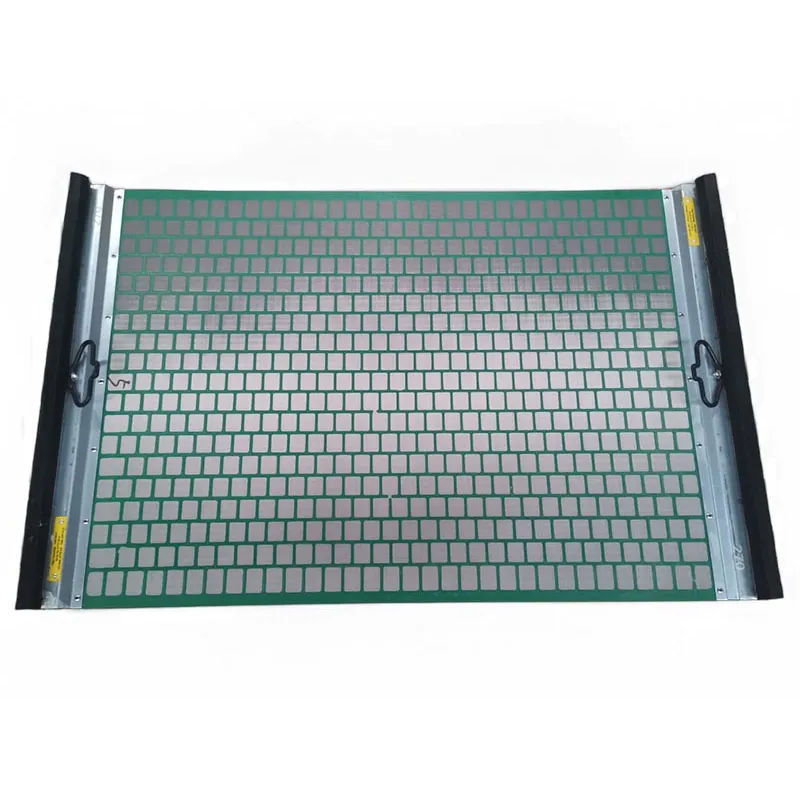

Metal grating is a vital component in various industries, providing solutions for flooring, drainage, and ventilation among others. Its strength and durability make it an indispensable material in construction, manufacturing, and infrastructure projects. As demand continues to rise, understanding the pricing dynamics of metal grating becomes essential for buyers and suppliers alike.

What is Metal Grating?

Metal grating is a type of open grid structure made from metal bars, typically steel or aluminum, designed to provide strength and support while allowing for the passage of light, air, and liquids. Commonly used in walkways, platforms, and stairways, metal grating offers safety features such as slip resistance and robust load-bearing capacities. Its applications range from industrial settings to architectural enhancements in commercial buildings.

Factors Influencing Metal Grating Prices

Several factors contribute to the price fluctuations of metal grating. These include

1. Material Costs The type of metal used significantly affects the price. For instance, aluminum grating is generally more expensive than steel due to its lightweight and corrosion-resistant properties. Market trends in raw material prices, which fluctuate based on global supply and demand, will also impact metal grating costs.

2. Manufacturing Processes The method used to produce the grating can influence its price. High-quality fabrication processes, such as welding or forging, may add to the overall cost, especially when combined with strict quality control measures. Furthermore, customized designs or specific dimensions tailored to client specifications can also lead to increased prices.

3. Market Demand As construction and industrial activities expand, the demand for metal grating rises, which can drive prices upwards. Seasonal variances in construction projects or unexpected surges in demand, such as those seen during economic recoveries, can cause significant fluctuations in metal grating prices.

4. Regulatory Standards Compliance with safety and quality standards can also affect pricing. Metal gratings that meet stringent regulations may incur higher costs due to added production requirements and testing. On the other hand, non-compliance can lead to cheaper products but may pose safety risks.

5. Geographical Factors The location of the buyer and seller can influence pricing as well. Shipping costs, taxes, and tariffs on imported metals can all impact the final price of metal grating. Local availability of materials can also provide an edge in pricing due to reduced transportation costs.

metal grating price

Current Market Trends

In recent years, the metal grating market has experienced significant growth, driven by increased infrastructural development and a focus on safety in industrial environments. The rapid expansion of sectors such as oil and gas, chemical processing, and construction has led to higher consumption of metal grating products. As sustainability becomes a focal point in construction, the use of recycled materials in manufacturing metal grating is also on the rise, affecting price structures positively for environmentally-conscious buyers.

Moreover, advancements in technology, such as the development of lightweight and stronger materials, have broadened the applications for metal grating. This evolution may influence market prices as newer materials become more widely adopted.

Strategies for Buying Metal Grating

For businesses looking to purchase metal grating, being informed about market trends and pricing can lead to better procurement decisions. Here are some strategies to consider

1. Bulk Purchasing Engaging in bulk purchases can often lead to discounts and better pricing terms from suppliers. 2. Supplier Relationships Establishing strong relationships with multiple suppliers can provide leverage in negotiations and ensure competitive pricing.

3. Market Research Staying updated on market trends and prices will help buyers understand the best times to purchase metal grating based on fluctuations in demand and supply.

4. Quality Assessment Prioritizing quality over price can lead to long-term savings. Cheaper options may lead to higher replacement costs down the line if they don’t meet safety and performance standards.

Conclusion

Understanding the pricing dynamics of metal grating is crucial for anyone involved in construction or industrial sectors. By considering factors like material costs, market demands, and supplier relationships, buyers can make informed decisions that optimize their investments. As the market continues to evolve, staying vigilant about trends and pricing will yield significant benefits in the purchasing strategy for metal grating.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024