- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 26, 2025 05:39

Back to list

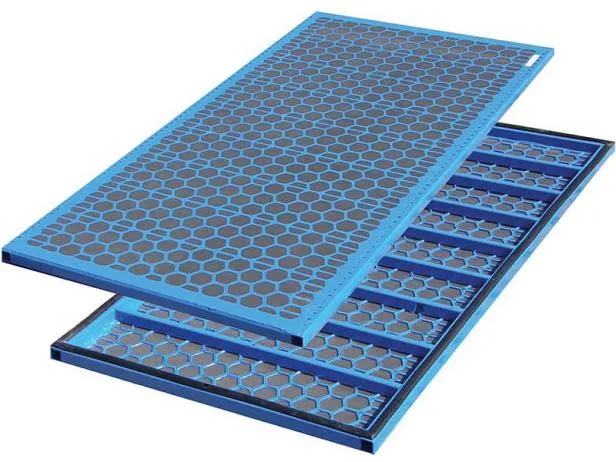

serrated steel grating

Navigating the world of industrial flooring solutions can be complex, with various materials and designs each offering distinct benefits. Among these, serrated bar grates have carved out a niche, thanks to their superior functionality and performance. These grates are especially revered in industries where safety and durability are paramount.

Beyond safety, another compelling advantage is adaptability. Serrated bar grates can be customized to suit specific project requirements, providing flexibility in terms of size, thickness, material, and coating. This customization is critical for industries with specialized operations that require bespoke grating solutions. For example, waste management facilities might need gratings with particular spacing to allow for effective debris filtering while ensuring robustness to support the weight of machinery. Expert consultation during the design phase ensures that the chosen configuration optimally meets operational demands while adhering to budget constraints. Trustworthiness is another pivotal factor when selecting serrated bar grates. Industrial operations cannot afford downtime due to subpar flooring solutions that might lead to accidents or require frequent maintenance. To this end, companies that have established a reputation for reliability and durability in their products are often preferred choices. Leading manufacturers conduct rigorous field tests alongside laboratory analysis to validate product performance under real-world conditions. End-users are thus assured of a product that not only meets but often exceeds expectations concerning longevity and safety. Furthermore, the environmental impact of construction materials cannot be overlooked. Many companies focused on sustainable development will find comfort in knowing that some serrated bar grates possess recyclability properties, especially those made from metals like steel and aluminum. This characteristic aligns with global efforts to reduce industrial carbon footprints, reinforcing a commitment to sustainability without sacrificing quality or performance. In conclusion, the selection of serrated bar grates is a decision that influences both operational efficiency and safety standards. Their design and material choices offer enhanced grip and adaptability, vital for varied industrial applications. The expertise and authority demonstrated by manufacturers instil confidence, ensuring that decisions are based not only on the immediate benefits but also on long-term trustworthiness. For any industry where safety, durability, and adaptability are non-negotiables, serrated bar grates present a worthy investment that remains unsurpassed in delivering practical benefits and peace of mind.

Beyond safety, another compelling advantage is adaptability. Serrated bar grates can be customized to suit specific project requirements, providing flexibility in terms of size, thickness, material, and coating. This customization is critical for industries with specialized operations that require bespoke grating solutions. For example, waste management facilities might need gratings with particular spacing to allow for effective debris filtering while ensuring robustness to support the weight of machinery. Expert consultation during the design phase ensures that the chosen configuration optimally meets operational demands while adhering to budget constraints. Trustworthiness is another pivotal factor when selecting serrated bar grates. Industrial operations cannot afford downtime due to subpar flooring solutions that might lead to accidents or require frequent maintenance. To this end, companies that have established a reputation for reliability and durability in their products are often preferred choices. Leading manufacturers conduct rigorous field tests alongside laboratory analysis to validate product performance under real-world conditions. End-users are thus assured of a product that not only meets but often exceeds expectations concerning longevity and safety. Furthermore, the environmental impact of construction materials cannot be overlooked. Many companies focused on sustainable development will find comfort in knowing that some serrated bar grates possess recyclability properties, especially those made from metals like steel and aluminum. This characteristic aligns with global efforts to reduce industrial carbon footprints, reinforcing a commitment to sustainability without sacrificing quality or performance. In conclusion, the selection of serrated bar grates is a decision that influences both operational efficiency and safety standards. Their design and material choices offer enhanced grip and adaptability, vital for varied industrial applications. The expertise and authority demonstrated by manufacturers instil confidence, ensuring that decisions are based not only on the immediate benefits but also on long-term trustworthiness. For any industry where safety, durability, and adaptability are non-negotiables, serrated bar grates present a worthy investment that remains unsurpassed in delivering practical benefits and peace of mind.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024