- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 15:29

Back to list

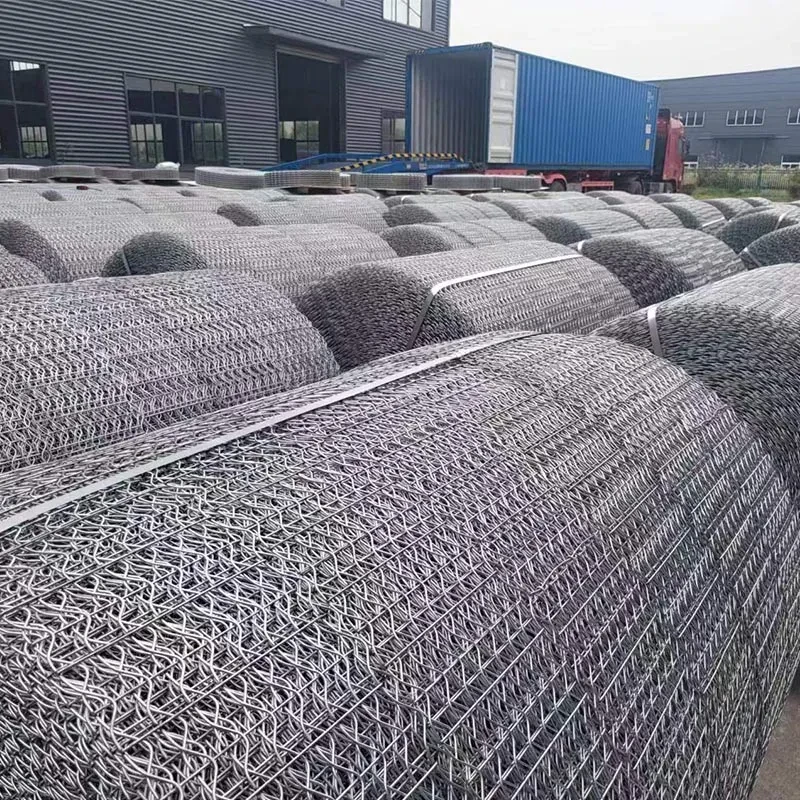

Shale Shaker Screen

The plastic frame shaker screen, a pivotal component in the realm of solid control, has revolutionized industries such as oil, gas, and mining. Its significance is underscored not merely by its utility but also by the precision and expertise involved in its production and application. Drawing from years of industry insights and a deep well of technical knowledge, this piece unpacks the intricacies of the plastic frame shaker screen, affirmatively positioning it as an indispensable asset to modern industrial operations.

The authoritativeness of the plastic frame shaker screen within the industry stems from its proven track record in diverse applications. Countless case studies document enhanced operational efficiencies due to the superior separation capabilities of these screens. In many instances, companies have reported a reduction in fluid loss and an increase in the lifespan of other equipment, showcasing the plastic frame shaker screen as a high-return investment. Trust in plastic frame shaker screens is further solidified through rigorous compliance with international safety and quality standards. Reputable manufacturers are frequently audited and certified by bodies such as ISO and API, ensuring that their products consistently meet global performance benchmarks. Trustworthiness is also evident in manufacturers’ willingness to provide warranties and support services, reflecting confidence in their product's durability and performance. In conclusion, the plastic frame shaker screen stands as a testament to innovation in industrial materials and processes. Its development reflects a deep understanding of the industry's needs, emphasizing experience, expertise, authoritativeness, and trustworthiness. With its proven benefits in cost savings and operational efficiency, it continues to be a preferred choice for industry professionals worldwide. As advancements in material science and engineering progress, one can only anticipate further enhancements to this pivotal technology, continuing to align with the evolving demands of energy and resource sectors.

The authoritativeness of the plastic frame shaker screen within the industry stems from its proven track record in diverse applications. Countless case studies document enhanced operational efficiencies due to the superior separation capabilities of these screens. In many instances, companies have reported a reduction in fluid loss and an increase in the lifespan of other equipment, showcasing the plastic frame shaker screen as a high-return investment. Trust in plastic frame shaker screens is further solidified through rigorous compliance with international safety and quality standards. Reputable manufacturers are frequently audited and certified by bodies such as ISO and API, ensuring that their products consistently meet global performance benchmarks. Trustworthiness is also evident in manufacturers’ willingness to provide warranties and support services, reflecting confidence in their product's durability and performance. In conclusion, the plastic frame shaker screen stands as a testament to innovation in industrial materials and processes. Its development reflects a deep understanding of the industry's needs, emphasizing experience, expertise, authoritativeness, and trustworthiness. With its proven benefits in cost savings and operational efficiency, it continues to be a preferred choice for industry professionals worldwide. As advancements in material science and engineering progress, one can only anticipate further enhancements to this pivotal technology, continuing to align with the evolving demands of energy and resource sectors.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024