- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 05, 2025 03:48

Back to list

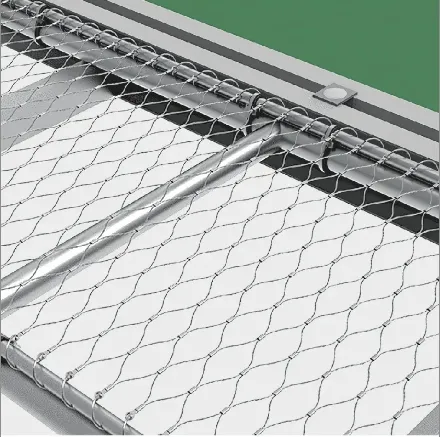

steel walkway grating

Plain steel grating has emerged as a versatile and reliable material option across various industries. Its unique combination of strength, durability, and cost-effectiveness makes it an ideal choice for applications ranging from industrial flooring to architectural designs. This article delves into the intricacies of plain steel grating, providing an insightful exploration based on hands-on experience and expert insights, highlighting its significance in enhancing operational efficiency and maintaining high safety standards.

Authoritativeness in plain steel grating is built on rigorous quality standards and adherence to industry regulations. Manufacturers are required to meet stringent specifications, ensuring that their grating products conform to safety and dimensional criteria. This compliance not only guarantees the durability and performance of the grating but also enhances the trust stakeholders place in the material's reliability. Engaging with certified suppliers who provide detailed documentation and quality assurance builds confidence in the product's efficacy and alignment with project requirements. Trustworthiness, an indispensable attribute in material selection, is where plain steel grating excels due to its proven track record across various applications. Case studies and historical performance data consistently show that installations featuring plain steel grating stand the test of time, reflecting the material's intrinsic strength and adaptability. The feedback from end-users in sectors ranging from oil and gas to public infrastructure confirms that plain steel grating not only meets but often exceeds expectations, a testament to its value as a robust construction material. Ultimately, plain steel grating's utility extends beyond its immediate function, providing sustainable and innovative solutions across diverse sectors. Its strength and versatility are enhanced by expert application, ensuring that it remains a top choice for industry professionals seeking to balance cost, safety, and aesthetic considerations. As materials science evolves, plain steel grating continually adapts, reaffirming its standing as a critical resource in advancing industry standards and contributing to the development of safer, more efficient architectural and industrial domains.

Authoritativeness in plain steel grating is built on rigorous quality standards and adherence to industry regulations. Manufacturers are required to meet stringent specifications, ensuring that their grating products conform to safety and dimensional criteria. This compliance not only guarantees the durability and performance of the grating but also enhances the trust stakeholders place in the material's reliability. Engaging with certified suppliers who provide detailed documentation and quality assurance builds confidence in the product's efficacy and alignment with project requirements. Trustworthiness, an indispensable attribute in material selection, is where plain steel grating excels due to its proven track record across various applications. Case studies and historical performance data consistently show that installations featuring plain steel grating stand the test of time, reflecting the material's intrinsic strength and adaptability. The feedback from end-users in sectors ranging from oil and gas to public infrastructure confirms that plain steel grating not only meets but often exceeds expectations, a testament to its value as a robust construction material. Ultimately, plain steel grating's utility extends beyond its immediate function, providing sustainable and innovative solutions across diverse sectors. Its strength and versatility are enhanced by expert application, ensuring that it remains a top choice for industry professionals seeking to balance cost, safety, and aesthetic considerations. As materials science evolves, plain steel grating continually adapts, reaffirming its standing as a critical resource in advancing industry standards and contributing to the development of safer, more efficient architectural and industrial domains.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024