- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 05, 2025 03:18

Back to list

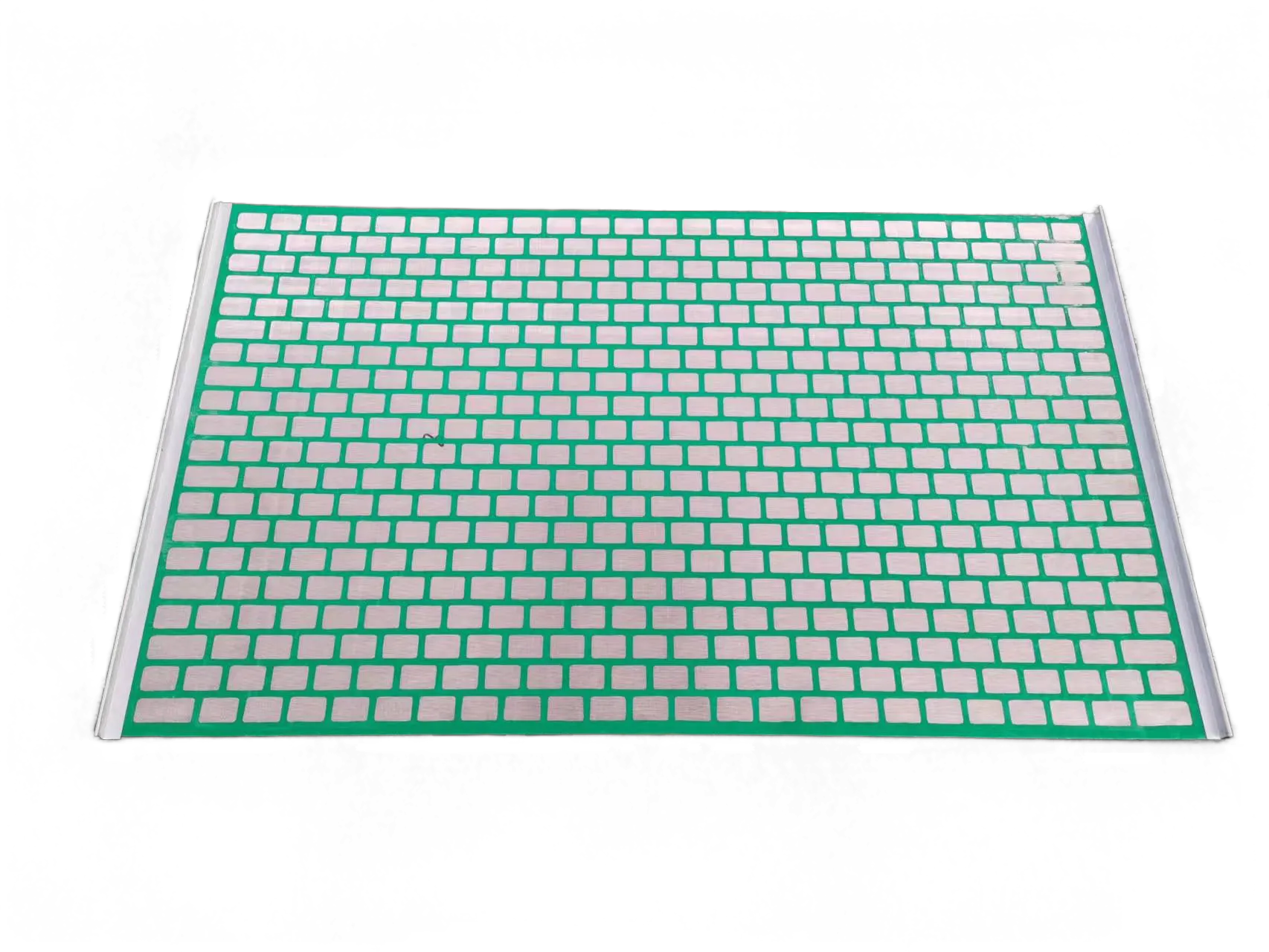

steel walkway grating

Hot dip galvanized steel grating has become an essential material in various industrial applications due to its durability, strength, and resistance to corrosion. This versatile product has earned its reputation in sectors ranging from construction to manufacturing, where it is prized for its ability to withstand harsh environments while providing necessary support and safety.

Furthermore, when considering the authoritativeness of hot dip galvanized steel grating, it is noteworthy that it is a preferred choice among engineers and designers. This is primarily due to its versatility, which allows for customization according to specific project requirements. Whether it’s for a small-scale installation or a massive infrastructure project, the ability to tailor the grating dimensions, load capacity, and finish provides a unique competitive edge. Trustworthiness is inherently linked to the product’s proven track record in diverse applications. Industries that have utilized hot dip galvanized steel grating report significant reductions in lifecycle costs, largely owing to its minimal maintenance requirements. The predictability of its performance under various conditions establishes it as a reliable component in structural design. In environmentally conscious times, the recyclability of galvanized steel cannot be overlooked. When the grating reaches the end of its life cycle, the steel and zinc elements can be recycled, contributing to sustainable building practices. This aspect not only benefits the environment but also supports businesses aiming to meet green certification requisites. In essence, hot dip galvanized steel grating harmonizes practical and economic benefits, making it an invaluable material in contemporary construction and industrial operations. Its resilience, compliance with standards, safety enhancements, and environmental efficiency all consolidate its standing as a trusted solution. For any company or contractor looking to invest in a dependable material that assures longevity and performance, hot dip galvanized steel grating is a wise choice. The ongoing advancements in galvanizing technologies continue to improve the properties of steel grating, ensuring it remains at the forefront of industrial materials. As industries evolve, the need for reliable, high-performance materials grows, and hot dip galvanized steel grating meets this demand with excellence, making its value undeniable in today’s market.

Furthermore, when considering the authoritativeness of hot dip galvanized steel grating, it is noteworthy that it is a preferred choice among engineers and designers. This is primarily due to its versatility, which allows for customization according to specific project requirements. Whether it’s for a small-scale installation or a massive infrastructure project, the ability to tailor the grating dimensions, load capacity, and finish provides a unique competitive edge. Trustworthiness is inherently linked to the product’s proven track record in diverse applications. Industries that have utilized hot dip galvanized steel grating report significant reductions in lifecycle costs, largely owing to its minimal maintenance requirements. The predictability of its performance under various conditions establishes it as a reliable component in structural design. In environmentally conscious times, the recyclability of galvanized steel cannot be overlooked. When the grating reaches the end of its life cycle, the steel and zinc elements can be recycled, contributing to sustainable building practices. This aspect not only benefits the environment but also supports businesses aiming to meet green certification requisites. In essence, hot dip galvanized steel grating harmonizes practical and economic benefits, making it an invaluable material in contemporary construction and industrial operations. Its resilience, compliance with standards, safety enhancements, and environmental efficiency all consolidate its standing as a trusted solution. For any company or contractor looking to invest in a dependable material that assures longevity and performance, hot dip galvanized steel grating is a wise choice. The ongoing advancements in galvanizing technologies continue to improve the properties of steel grating, ensuring it remains at the forefront of industrial materials. As industries evolve, the need for reliable, high-performance materials grows, and hot dip galvanized steel grating meets this demand with excellence, making its value undeniable in today’s market.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024