- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 12:37

Back to list

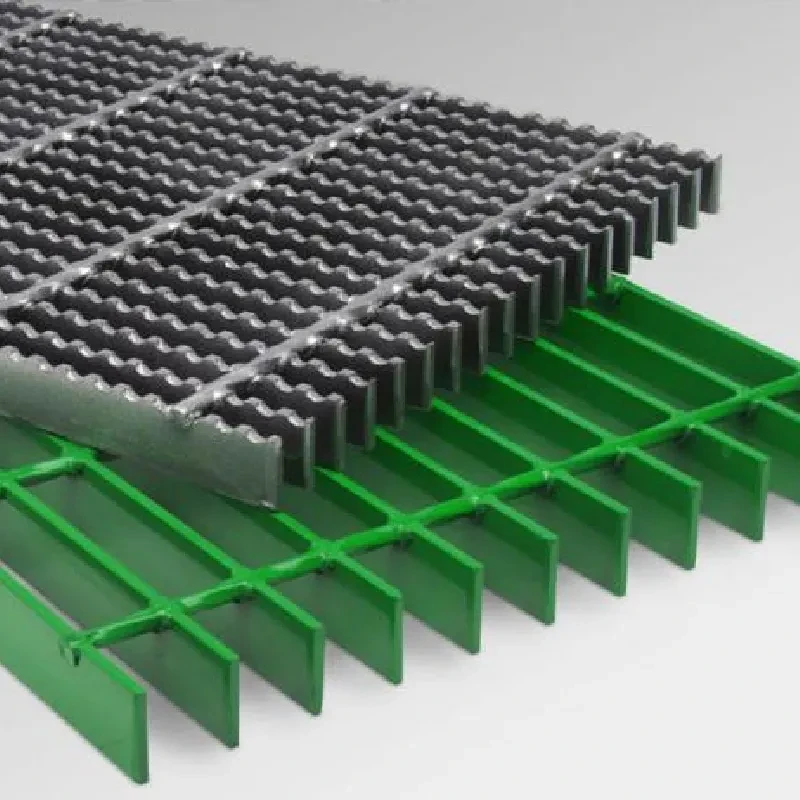

steel walkway mesh

Pipeline reinforced mesh has become an essential component in a wide array of industries, revolutionizing the way pipelines are constructed and maintained. This cutting-edge technology delivers unprecedented durability and strength, ensuring optimum performance under the most demanding conditions.

Trustworthiness is of utmost importance when industries decide to embrace new technologies. With pipeline reinforced mesh, trust is built through rigorous testing and adherence to international safety standards. Manufacturers subjected their mesh products to extensive mechanical testing under extreme pressure and environmental conditions, ensuring they meet or exceed the required performance criteria. Testimonials from industry leaders further reaffirm the reliability of reinforced mesh, with many citing a reduction in maintenance costs and an extension of pipeline life after transitioning to this technology. Product advancements continue to push the boundaries of what pipeline reinforced mesh can accomplish. Recent innovations include the development of eco-friendly materials that do not compromise on strength or durability while reducing environmental impact. Furthermore, advancements in manufacturing processes have resulted in customized reinforced mesh solutions, tailored to meet the specific needs of diverse pipeline projects. As industries evolve, so does the technology, ensuring that reinforced mesh remains at the forefront of pipeline innovation. For companies considering an investment in pipeline infrastructure, adopting reinforced mesh offers a strategic advantage. The initial costs are often offset by the long-term savings associated with reduced maintenance and enhanced pipeline performance. Additionally, its implementation signifies a commitment to adopting state-of-the-art technologies, positioning an organization as a leader in sustainability and innovation. In conclusion, pipeline reinforced mesh stands as a testament to the remarkable progress in engineering technology. Its proven performance, endorsed by industry experts, and its capacity to withstand challenging conditions solidifies its role as an indispensable tool for modern pipeline projects. As industries continue to seek solutions that balance performance with cost-effectiveness and sustainability, pipeline reinforced mesh emerges as the ideal choice, setting the standard for future innovations in pipeline construction and maintenance.

Trustworthiness is of utmost importance when industries decide to embrace new technologies. With pipeline reinforced mesh, trust is built through rigorous testing and adherence to international safety standards. Manufacturers subjected their mesh products to extensive mechanical testing under extreme pressure and environmental conditions, ensuring they meet or exceed the required performance criteria. Testimonials from industry leaders further reaffirm the reliability of reinforced mesh, with many citing a reduction in maintenance costs and an extension of pipeline life after transitioning to this technology. Product advancements continue to push the boundaries of what pipeline reinforced mesh can accomplish. Recent innovations include the development of eco-friendly materials that do not compromise on strength or durability while reducing environmental impact. Furthermore, advancements in manufacturing processes have resulted in customized reinforced mesh solutions, tailored to meet the specific needs of diverse pipeline projects. As industries evolve, so does the technology, ensuring that reinforced mesh remains at the forefront of pipeline innovation. For companies considering an investment in pipeline infrastructure, adopting reinforced mesh offers a strategic advantage. The initial costs are often offset by the long-term savings associated with reduced maintenance and enhanced pipeline performance. Additionally, its implementation signifies a commitment to adopting state-of-the-art technologies, positioning an organization as a leader in sustainability and innovation. In conclusion, pipeline reinforced mesh stands as a testament to the remarkable progress in engineering technology. Its proven performance, endorsed by industry experts, and its capacity to withstand challenging conditions solidifies its role as an indispensable tool for modern pipeline projects. As industries continue to seek solutions that balance performance with cost-effectiveness and sustainability, pipeline reinforced mesh emerges as the ideal choice, setting the standard for future innovations in pipeline construction and maintenance.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

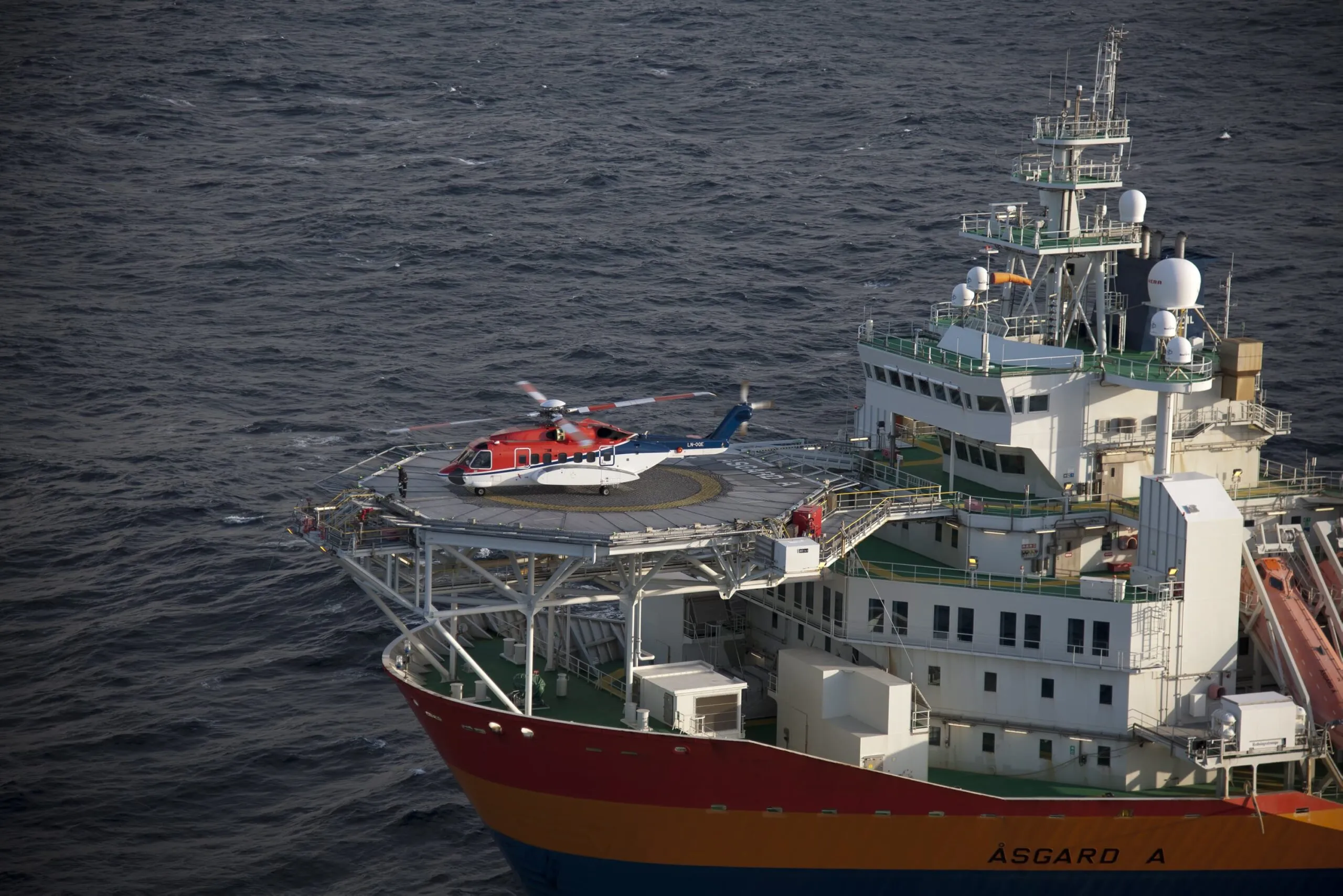

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024