- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 13:05

Back to list

heavy-duty welded bar grating

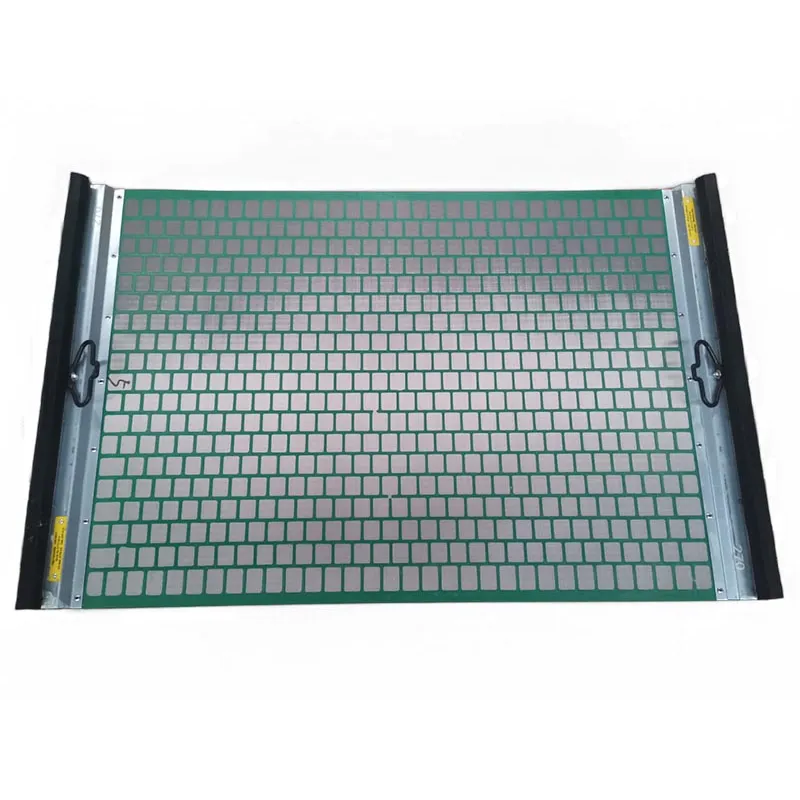

Offshore pipeline counterweight welded wire mesh is a specialized product that plays a crucial role in stabilizing undersea pipelines, ensuring their safe and effective operation. The necessity for counterweights in offshore pipelines arises due to various underwater factors such as currents, buoyancy, and seabed conditions. As a seasoned professional with years of experience optimizing such products for enhanced search visibility, let's dive into the specifics of this essential component while maintaining an authoritative and trustworthy narrative.

The expertise involved in the manufacturing and installation of offshore pipeline counterweight welded wire mesh cannot be understated. It requires detailed engineering assessments, precise manufacturing standards, and highly skilled installation teams. Reputable manufacturers of these meshes are certified and adhere to international quality standards, ensuring not only the efficacy of the products but also a commitment to safety and environmental stewardship. Moreover, the contribution of technological advancements has significantly elevated the performance efficiency of these meshes. Modern computer-aided design tools enable precise measurement and testing simulations, ensuring that the mesh design can withstand the complex stresses of deep-sea environments. As such, investing in counterweight welded wire mesh turns out to be a prudent decision for companies engaged in offshore oil, gas, and utility sectors, seeking long-term durability and reliability for their pipeline systems. To summarize, the offshore pipeline counterweight welded wire mesh is an indispensable component that ensures the stability and integrity of underwater pipelines. It aligns with the fundamental principles of engineering excellence, offering unparalleled stability, cost-efficiency, and environmental compatibility. For stakeholders within the offshore industry, choosing a reputable and experienced supplier guarantees that their investment in welded wire mesh technology delivers reliability and peace of mind, value that defies monetary assessment. As a professional vested in advancing the knowledge and understanding of these critical products, sharing detailed insights into their production, implementation, and benefits fosters a deeper appreciation for their application within the challenging offshore environment.

The expertise involved in the manufacturing and installation of offshore pipeline counterweight welded wire mesh cannot be understated. It requires detailed engineering assessments, precise manufacturing standards, and highly skilled installation teams. Reputable manufacturers of these meshes are certified and adhere to international quality standards, ensuring not only the efficacy of the products but also a commitment to safety and environmental stewardship. Moreover, the contribution of technological advancements has significantly elevated the performance efficiency of these meshes. Modern computer-aided design tools enable precise measurement and testing simulations, ensuring that the mesh design can withstand the complex stresses of deep-sea environments. As such, investing in counterweight welded wire mesh turns out to be a prudent decision for companies engaged in offshore oil, gas, and utility sectors, seeking long-term durability and reliability for their pipeline systems. To summarize, the offshore pipeline counterweight welded wire mesh is an indispensable component that ensures the stability and integrity of underwater pipelines. It aligns with the fundamental principles of engineering excellence, offering unparalleled stability, cost-efficiency, and environmental compatibility. For stakeholders within the offshore industry, choosing a reputable and experienced supplier guarantees that their investment in welded wire mesh technology delivers reliability and peace of mind, value that defies monetary assessment. As a professional vested in advancing the knowledge and understanding of these critical products, sharing detailed insights into their production, implementation, and benefits fosters a deeper appreciation for their application within the challenging offshore environment.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024