- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 01, 2025 02:25

Back to list

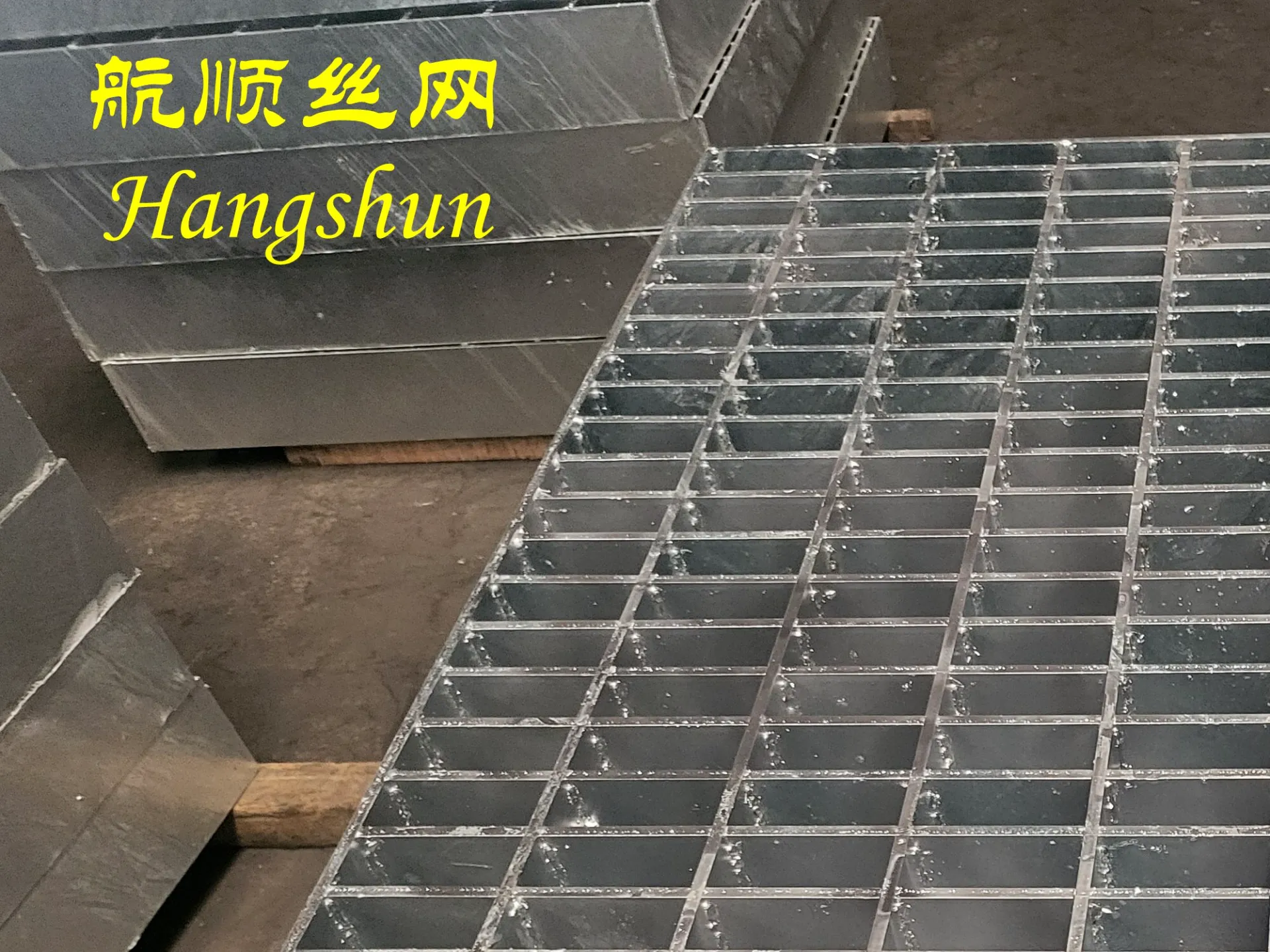

serrated steel grating

Non-serrated gratings have taken center stage in industries where precision, safety, and efficiency are paramount. As a trusted component in infrastructure projects, industrial floors, and architecture, non-serrated gratings offer unique advantages that are often underestimated. Let’s delve into why these gratings are a crucial choice and how they enhance both the practical and functional aspects of various applications.

When it comes to maintenance, non-serrated gratings offer a distinct edge. Their smooth surfaces result in easier cleaning and reduced maintenance efforts compared to serrated alternatives. Quick and simple upkeep translates to lower operational costs for businesses and public facilities, as cleaning processes are often less time-consuming and require less intensive labor. This cost efficiency is a vital consideration for any budget-conscious project managers and facility supervisors. Selecting non-serrated gratings also aligns with sustainability goals. Certain materials used in these gratings, like recycled aluminum or eco-friendly fiberglass, support green building certifications. Additionally, their durability and low maintenance needs mean fewer replacements over time, reducing waste and resource consumption. As the demand for sustainable building solutions rises, non-serrated gratings offer an avenue for companies and developers to meet environmental standards while still attaining practical benefits. The installation of non-serrated gratings is another area where they excel. The simplicity associated with their setup can often result in reduced installation times and costs. For project managers, this efficiency can translate into fewer labor hours and less operational downtime, ensuring projects remain on schedule and within budget. This aspect is crucial in fast-paced construction environments where time is money, and any delays can lead to significant financial consequences. While non-serrated gratings are already advantageous, ongoing innovations continue to enhance their utility. Advances in material science are producing even more robust and lighter grating options, ensuring that they can meet the specific demands of emerging industries. Furthermore, developments in anti-corrosion coatings are expanding their applicability to harsher environments, such as chemical processing plants or offshore facilities. In conclusion, non-serrated gratings offer unparalleled safety, durability, and aesthetic appeal, making them an insightful choice for a variety of applications. Their versatility across multiple sectors showcases their indispensability for both small-scale and massive infrastructure projects. As industries continue to evolve, non-serrated gratings will undoubtedly remain at the forefront, championing efficiency, safety, and sustainability. Whether in public, industrial, or aesthetic applications, they stand as a testament to thoughtful design and engineering excellence.

When it comes to maintenance, non-serrated gratings offer a distinct edge. Their smooth surfaces result in easier cleaning and reduced maintenance efforts compared to serrated alternatives. Quick and simple upkeep translates to lower operational costs for businesses and public facilities, as cleaning processes are often less time-consuming and require less intensive labor. This cost efficiency is a vital consideration for any budget-conscious project managers and facility supervisors. Selecting non-serrated gratings also aligns with sustainability goals. Certain materials used in these gratings, like recycled aluminum or eco-friendly fiberglass, support green building certifications. Additionally, their durability and low maintenance needs mean fewer replacements over time, reducing waste and resource consumption. As the demand for sustainable building solutions rises, non-serrated gratings offer an avenue for companies and developers to meet environmental standards while still attaining practical benefits. The installation of non-serrated gratings is another area where they excel. The simplicity associated with their setup can often result in reduced installation times and costs. For project managers, this efficiency can translate into fewer labor hours and less operational downtime, ensuring projects remain on schedule and within budget. This aspect is crucial in fast-paced construction environments where time is money, and any delays can lead to significant financial consequences. While non-serrated gratings are already advantageous, ongoing innovations continue to enhance their utility. Advances in material science are producing even more robust and lighter grating options, ensuring that they can meet the specific demands of emerging industries. Furthermore, developments in anti-corrosion coatings are expanding their applicability to harsher environments, such as chemical processing plants or offshore facilities. In conclusion, non-serrated gratings offer unparalleled safety, durability, and aesthetic appeal, making them an insightful choice for a variety of applications. Their versatility across multiple sectors showcases their indispensability for both small-scale and massive infrastructure projects. As industries continue to evolve, non-serrated gratings will undoubtedly remain at the forefront, championing efficiency, safety, and sustainability. Whether in public, industrial, or aesthetic applications, they stand as a testament to thoughtful design and engineering excellence.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024