- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 05:22

Back to list

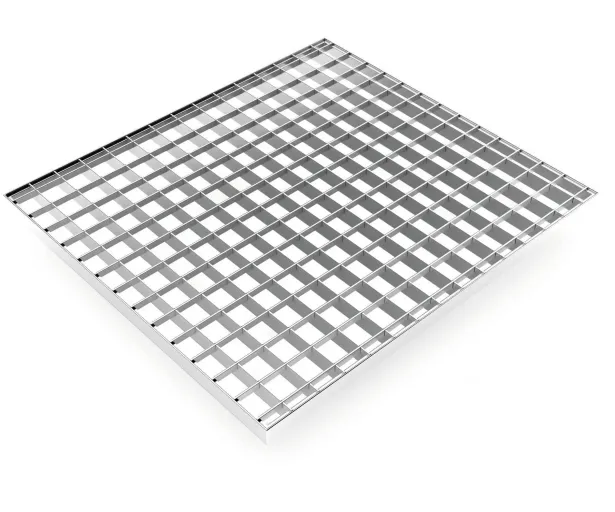

metal grating for sale

Metal mesh grating has emerged as a versatile and indispensable component across various industries. Known for its robustness and adaptability, metal mesh grating offers solutions tailored to meet specific requirements in industrial, architectural, and commercial applications.

Safety is an intrinsic aspect of metal mesh grating, closely tied to the credibility and reliability of its application. Slip resistance is an essential feature, particularly within industrial settings, where the risk of accidents must be minimized. Advanced manufacturing techniques, such as serration and specific surface treatments, enhance the grip and safety characteristics of metal mesh grating. The future of metal mesh grating lies in sustainable practices. Innovations are steering towards environmentally friendly materials and energy-efficient production methods. As the construction and manufacturing sectors shift towards sustainability, the demand for eco-friendly metal mesh grating solutions is anticipated to grow. These practices not only contribute to ecological conservation but also align with the modern consumer's awareness and demand for responsible sourcing. Metal mesh grating thus stands at the confluence of safety, utility, and design. Each installation, whether in a high-traffic industrial area or a sleek architectural project, tells a story of engineered precision and thoughtful application. The ongoing research and development in materials and manufacturing techniques promise a future where metal mesh grating continues to lead as a reliable and multifunctional component across diverse uses. While the advent of 3D printing and smart materials is pushing the boundaries of what can be achieved with metal mesh grating, the core values of durability, safety, and versatility remain steadfast. It is these values that underline the product's enduring appeal and its status as a cornerstone in both traditional and contemporary applications. As industries evolve, the role of metal mesh grating will undoubtedly expand, offering new solutions to complex challenges. By staying at the forefront of industry advancements, we ensure that our knowledge and expertise in metal mesh grating remain unmatched, providing clients with the dependable products and insights they need to succeed in their endeavors.

Safety is an intrinsic aspect of metal mesh grating, closely tied to the credibility and reliability of its application. Slip resistance is an essential feature, particularly within industrial settings, where the risk of accidents must be minimized. Advanced manufacturing techniques, such as serration and specific surface treatments, enhance the grip and safety characteristics of metal mesh grating. The future of metal mesh grating lies in sustainable practices. Innovations are steering towards environmentally friendly materials and energy-efficient production methods. As the construction and manufacturing sectors shift towards sustainability, the demand for eco-friendly metal mesh grating solutions is anticipated to grow. These practices not only contribute to ecological conservation but also align with the modern consumer's awareness and demand for responsible sourcing. Metal mesh grating thus stands at the confluence of safety, utility, and design. Each installation, whether in a high-traffic industrial area or a sleek architectural project, tells a story of engineered precision and thoughtful application. The ongoing research and development in materials and manufacturing techniques promise a future where metal mesh grating continues to lead as a reliable and multifunctional component across diverse uses. While the advent of 3D printing and smart materials is pushing the boundaries of what can be achieved with metal mesh grating, the core values of durability, safety, and versatility remain steadfast. It is these values that underline the product's enduring appeal and its status as a cornerstone in both traditional and contemporary applications. As industries evolve, the role of metal mesh grating will undoubtedly expand, offering new solutions to complex challenges. By staying at the forefront of industry advancements, we ensure that our knowledge and expertise in metal mesh grating remain unmatched, providing clients with the dependable products and insights they need to succeed in their endeavors.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024