- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 05:47

Back to list

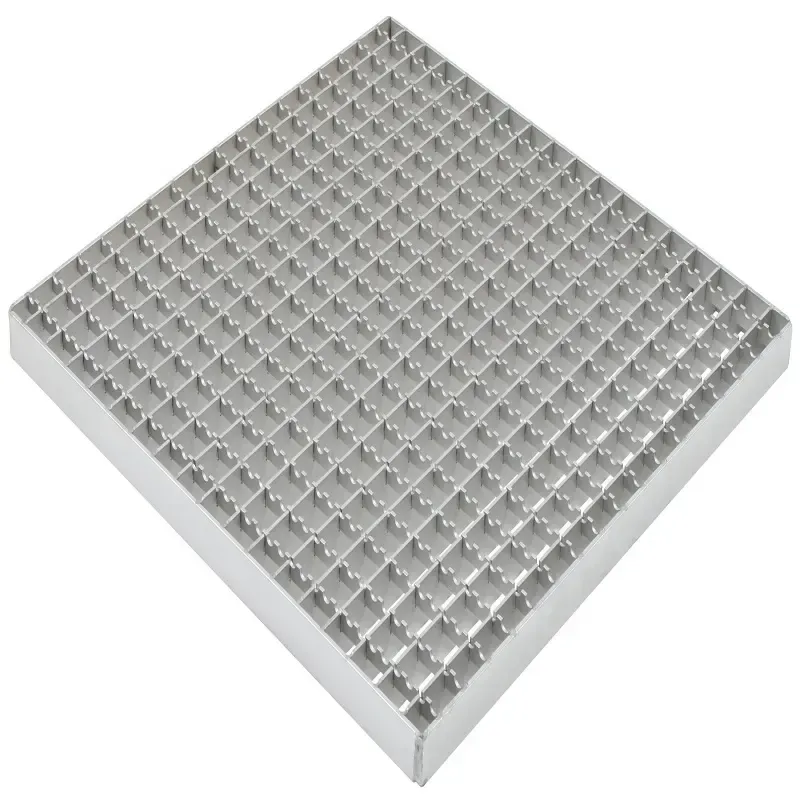

floor steel grating

Industrial floor grating is an integral component in various industries where safety, efficiency, and durability are paramount. Providing a sturdy and reliable surface, industrial grating is primarily employed in environments that demand high levels of tensile strength and resilience against environmental stressors. This article dives into the essential qualities, applications, and innovations surrounding industrial floor grating, offering valuable insights that emphasize experience, expertise, authority, and trustworthiness.

The expertise extends to understanding industry standards and regulations that govern the use of industrial floor grating. Knowledge of OSHA and ANSI regulations is indispensable for ensuring compliance and maintaining workplace safety. Transparent communication with regulatory authorities and continuous education on industry updates fortify a business's reputation for authority and credibility. In recent years, technological advancements have propelled innovations in industrial floor grating. Industry leaders are experimenting with composite materials and incorporating sensor technology to transform conventional grating systems into smart safety platforms. These intelligent gratings can detect load changes and environmental shifts, alerting operators to potential hazards, thereby preventing mishaps before they occur. Companies investing in these sustainable and advanced grating solutions not only enhance their operational safety but also demonstrate a commitment to technological progression and ecological stewardship, reinforcing their position as industry pioneers. Selecting the right industrial floor grating is instrumental in safeguarding worker welfare and ensuring the seamless operation of industrial facilities. Collaboration with manufacturers and suppliers who prioritize quality assurance and offer comprehensive post-purchase support fosters trust and guarantees long-term satisfaction. Testimonials from clients who have switched to more advanced grating solutions attest to increased productivity and reduced incident rates, underlining the significance of investing in the future. In conclusion, industrial floor grating is more than just a functional element; it's a strategic component that enhances safety, efficiency, and sustainability across diverse sectors. The right choice not only mitigates risks and fulfills regulatory requirements but also instills confidence and trustworthiness in a company's commitment to quality and innovation. As industries evolve, the role of industrial grating will continue to expand, driven by experience, expertise, authority, and trust.

The expertise extends to understanding industry standards and regulations that govern the use of industrial floor grating. Knowledge of OSHA and ANSI regulations is indispensable for ensuring compliance and maintaining workplace safety. Transparent communication with regulatory authorities and continuous education on industry updates fortify a business's reputation for authority and credibility. In recent years, technological advancements have propelled innovations in industrial floor grating. Industry leaders are experimenting with composite materials and incorporating sensor technology to transform conventional grating systems into smart safety platforms. These intelligent gratings can detect load changes and environmental shifts, alerting operators to potential hazards, thereby preventing mishaps before they occur. Companies investing in these sustainable and advanced grating solutions not only enhance their operational safety but also demonstrate a commitment to technological progression and ecological stewardship, reinforcing their position as industry pioneers. Selecting the right industrial floor grating is instrumental in safeguarding worker welfare and ensuring the seamless operation of industrial facilities. Collaboration with manufacturers and suppliers who prioritize quality assurance and offer comprehensive post-purchase support fosters trust and guarantees long-term satisfaction. Testimonials from clients who have switched to more advanced grating solutions attest to increased productivity and reduced incident rates, underlining the significance of investing in the future. In conclusion, industrial floor grating is more than just a functional element; it's a strategic component that enhances safety, efficiency, and sustainability across diverse sectors. The right choice not only mitigates risks and fulfills regulatory requirements but also instills confidence and trustworthiness in a company's commitment to quality and innovation. As industries evolve, the role of industrial grating will continue to expand, driven by experience, expertise, authority, and trust.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024