- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 21:00

Back to list

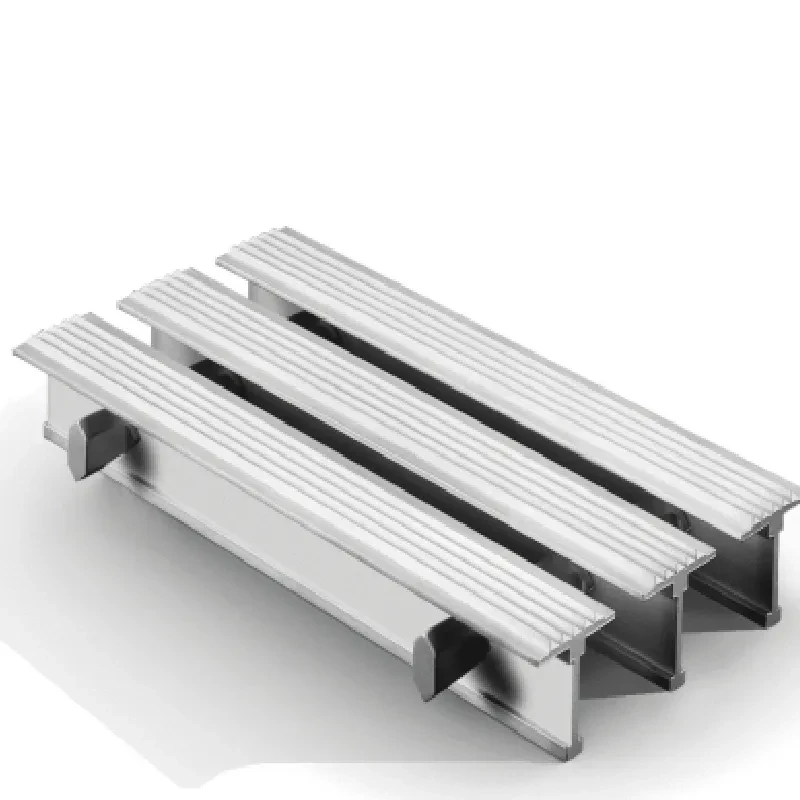

metal grating panels

Metal grating panels have emerged as an indispensable component in various industrial and architectural applications, offering not just a functional element, but also an enhancement to safety and design. Their evolution spans across decades, embodying a blend of engineering precision and aesthetic finesse, thereby becoming a staple for professionals who seek reliability combined with versatility.

Furthermore, these panels support sustainable construction practices. Many metal grating products are made from recycled materials and are themselves recyclable, aligning with growing ecological considerations. The environmental impact is minimized when combined with their superior lifespan and reduced frequency of replacement, offering businesses a sustainable option that does not compromise on performance. In terms of design flexibility, metal grating panels offer diverse applications. Customizable options allow for the creation of distinctive architectural elements, where perforations and designs can be tailored to client specifications, enhancing both functionality and aesthetics. Their integration into modern architectural projects is not just about meeting functional requirements but also about contributing to the overall design language, making them an esteemed choice for designers and architects alike. Finally, embracing metal grating panels enthuses a culture of innovation and safety in workplaces. As industries strive for efficiency, these panels offer scalable solutions that cater to both evolving standards and aesthetic requirements, setting a benchmark in modern industrial applications. They stand as a testament to versatile engineering, where functionality meets enduring quality — a choice backed by legacy, and strengthened by trust among industry leaders and innovators. In conclusion, the hybrid of experience, expertise, authority, and trustworthiness positions metal grating panels not just as a product but as an essential feature of modern infrastructure, facilitating advancements in safety, sustainability, and design.

Furthermore, these panels support sustainable construction practices. Many metal grating products are made from recycled materials and are themselves recyclable, aligning with growing ecological considerations. The environmental impact is minimized when combined with their superior lifespan and reduced frequency of replacement, offering businesses a sustainable option that does not compromise on performance. In terms of design flexibility, metal grating panels offer diverse applications. Customizable options allow for the creation of distinctive architectural elements, where perforations and designs can be tailored to client specifications, enhancing both functionality and aesthetics. Their integration into modern architectural projects is not just about meeting functional requirements but also about contributing to the overall design language, making them an esteemed choice for designers and architects alike. Finally, embracing metal grating panels enthuses a culture of innovation and safety in workplaces. As industries strive for efficiency, these panels offer scalable solutions that cater to both evolving standards and aesthetic requirements, setting a benchmark in modern industrial applications. They stand as a testament to versatile engineering, where functionality meets enduring quality — a choice backed by legacy, and strengthened by trust among industry leaders and innovators. In conclusion, the hybrid of experience, expertise, authority, and trustworthiness positions metal grating panels not just as a product but as an essential feature of modern infrastructure, facilitating advancements in safety, sustainability, and design.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024