- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 21:17

Back to list

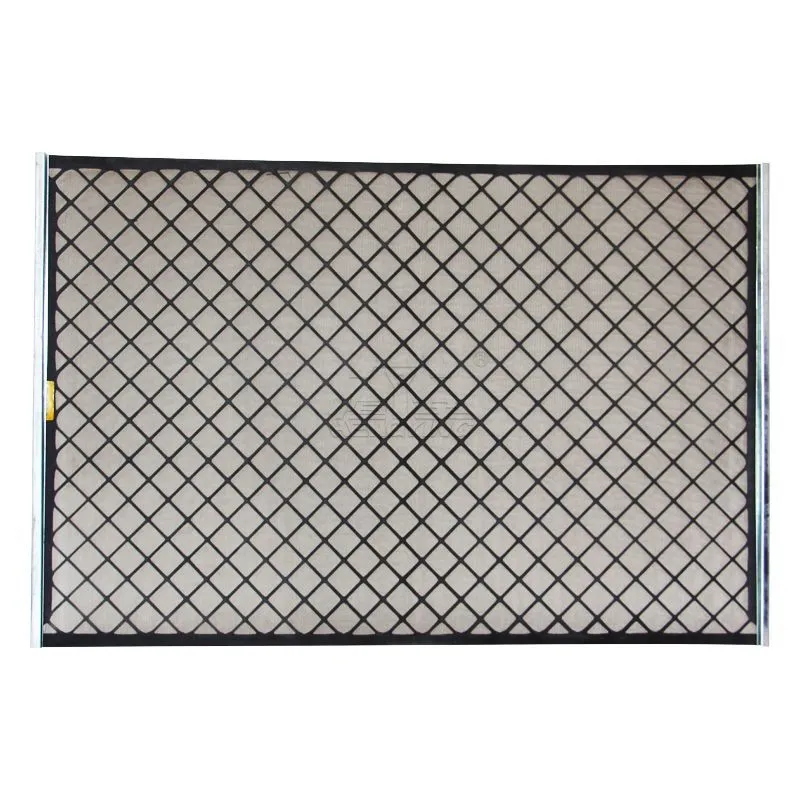

heavy-duty welded bar grating

Industrial environments demand robust and reliable components to withstand rigorous conditions and ensure safety and efficiency. Heavy duty metal grating is one such indispensable element, finding applications in platforms, walkways, catwalks, and drainage covers. This comprehensive guide explores the critical aspects of heavy duty metal grating, providing insights grounded in experience and expertise, and underscoring its authoritative role in industrial setups.

Trustworthiness in the heavy duty metal grating market is built on a foundation of compliance with industry standards and certifications. Professionals seeking high-quality grating should look for products that meet or exceed standards such as ANSI/NAAMM MBG 531. These standards ensure that the gratings have been tested for load-bearing capacity, corrosion resistance, and safety features. Choosing certified products from reputable manufacturers provides assurance of quality and performance. Another dimension of trust is the environmental impact of metal grating products. Eco-conscious industries are now considering the sustainability aspect of their materials and processes. Many manufacturers are adopting environmentally friendly practices, such as using recycled materials and implementing energy-efficient production methods. Opting for such products not only supports environmental conservation but also helps organizations meet regulatory requirements and enhance their corporate image. Maintenance is another critical factor influencing the longevity and performance of heavy duty metal grating. Regular inspections and cleaning schedules ensure that gratings remain free from debris that could potentially compromise their functionality. Protective coatings and treatments can also be applied to enhance their resistance to wear and environmental damage, further extending their service life. In conclusion, heavy duty metal grating is much more than a structural component; it is a cornerstone of industrial safety and efficiency. Its role in providing a durable, safe, and reliable solution in demanding environments makes it an authoritative choice for engineers and industry professionals. By understanding the nuances of material selection, manufacturing excellence, and maintenance best practices, stakeholders can make informed decisions that enhance operational integrity and trustworthiness, ultimately contributing to safer and more efficient industrial operations.

Trustworthiness in the heavy duty metal grating market is built on a foundation of compliance with industry standards and certifications. Professionals seeking high-quality grating should look for products that meet or exceed standards such as ANSI/NAAMM MBG 531. These standards ensure that the gratings have been tested for load-bearing capacity, corrosion resistance, and safety features. Choosing certified products from reputable manufacturers provides assurance of quality and performance. Another dimension of trust is the environmental impact of metal grating products. Eco-conscious industries are now considering the sustainability aspect of their materials and processes. Many manufacturers are adopting environmentally friendly practices, such as using recycled materials and implementing energy-efficient production methods. Opting for such products not only supports environmental conservation but also helps organizations meet regulatory requirements and enhance their corporate image. Maintenance is another critical factor influencing the longevity and performance of heavy duty metal grating. Regular inspections and cleaning schedules ensure that gratings remain free from debris that could potentially compromise their functionality. Protective coatings and treatments can also be applied to enhance their resistance to wear and environmental damage, further extending their service life. In conclusion, heavy duty metal grating is much more than a structural component; it is a cornerstone of industrial safety and efficiency. Its role in providing a durable, safe, and reliable solution in demanding environments makes it an authoritative choice for engineers and industry professionals. By understanding the nuances of material selection, manufacturing excellence, and maintenance best practices, stakeholders can make informed decisions that enhance operational integrity and trustworthiness, ultimately contributing to safer and more efficient industrial operations.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024