- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 15:51

Back to list

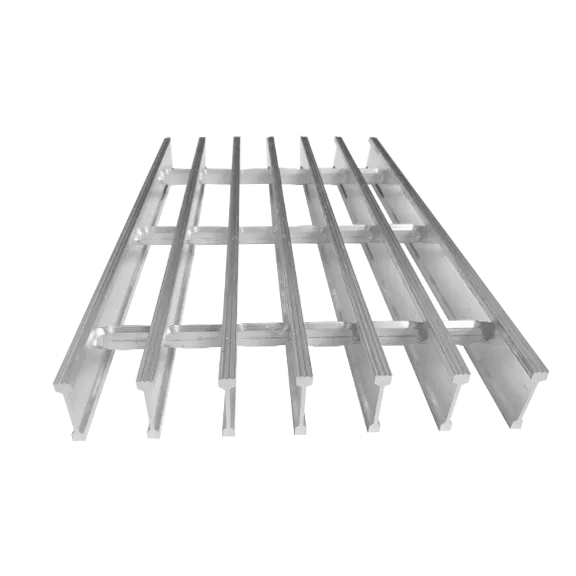

Swage-Locked Steel Grating

Metal grating, a versatile and durable solution, has become a staple in various industries due to its robustness and functionality. This article will delve into the myriad applications, benefits, and expertise-backed insights on metal grating, providing an authoritative guide to understanding its relevance in today's industrial and architectural landscapes.

Trustworthiness in the metal grating industry is built through compliance with international standards such as the ASTM and EN. These standards ensure products meet stringent safety and quality benchmarks, providing peace of mind to end-users. Companies that adhere to these standards demonstrate a commitment to quality and safety, establishing themselves as reputable suppliers in the market. For businesses considering metal grating as a solution, understanding the total cost of ownership is essential. While the initial investment may appear significant, the long-term benefits such as reduced maintenance costs, durability, and safety enhancements far outweigh the upfront expense. Engaging with suppliers who offer comprehensive consultancy services, including site assessments and custom grating solutions, can provide invaluable insights, helping businesses make informed decisions tailored to their specific needs. Exploring case studies where metal grating has transformed operations can further illustrate its value. For example, in a wastewater treatment plant, the implementation of stainless steel grating reduced maintenance downtime by over 30%, directly impacting operational efficiency. Such real-world examples underscore the importance of choosing the right type of grating and leveraging expert advice to ensure successful implementation. In conclusion, metal grating is a pivotal component across various sectors, providing unmatched strength, safety, and aesthetic appeal. Expertise in selecting the appropriate material, adhering to industry standards, and understanding its application nuances enhances its utility. Businesses that invest in high-quality metal grating solutions benefit from long-term savings, operational efficiency, and enhanced safety protocols, underscoring its integral role in modern infrastructure and design.

Trustworthiness in the metal grating industry is built through compliance with international standards such as the ASTM and EN. These standards ensure products meet stringent safety and quality benchmarks, providing peace of mind to end-users. Companies that adhere to these standards demonstrate a commitment to quality and safety, establishing themselves as reputable suppliers in the market. For businesses considering metal grating as a solution, understanding the total cost of ownership is essential. While the initial investment may appear significant, the long-term benefits such as reduced maintenance costs, durability, and safety enhancements far outweigh the upfront expense. Engaging with suppliers who offer comprehensive consultancy services, including site assessments and custom grating solutions, can provide invaluable insights, helping businesses make informed decisions tailored to their specific needs. Exploring case studies where metal grating has transformed operations can further illustrate its value. For example, in a wastewater treatment plant, the implementation of stainless steel grating reduced maintenance downtime by over 30%, directly impacting operational efficiency. Such real-world examples underscore the importance of choosing the right type of grating and leveraging expert advice to ensure successful implementation. In conclusion, metal grating is a pivotal component across various sectors, providing unmatched strength, safety, and aesthetic appeal. Expertise in selecting the appropriate material, adhering to industry standards, and understanding its application nuances enhances its utility. Businesses that invest in high-quality metal grating solutions benefit from long-term savings, operational efficiency, and enhanced safety protocols, underscoring its integral role in modern infrastructure and design.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024