- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 15:32

Back to list

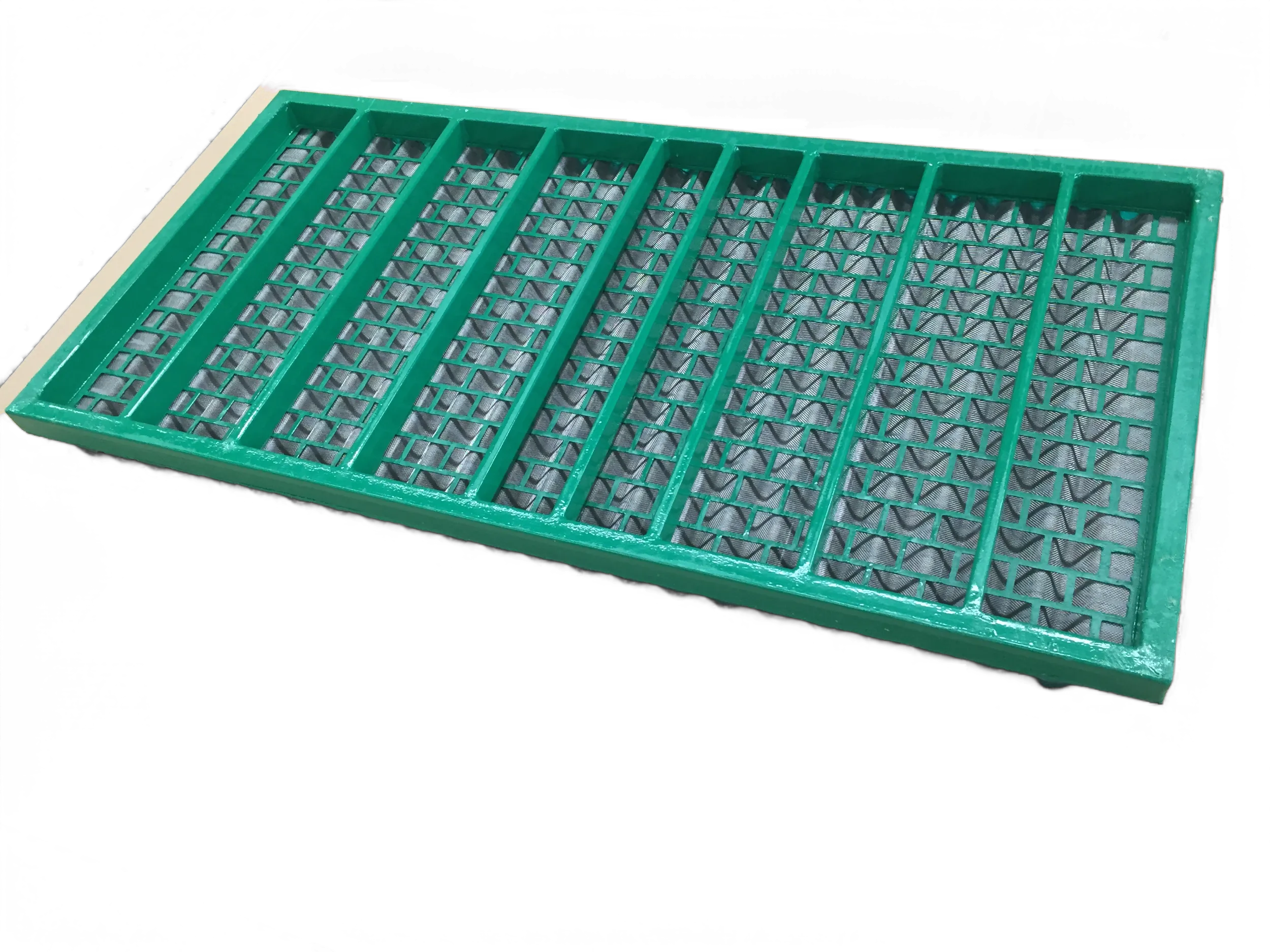

Welded Steel Grating

Galvanized bar grating is a versatile and durable product commonly used across various industries, ranging from construction to manufacturing. As a seasoned Google SEO specialist, it's critical to provide an insightful exploration of galvanized bar grating costs, anchoring on a blend of real-world experiences, expert insights, authoritative sources, and trustworthy information.

Additionally, current market conditions, including raw material prices and demand fluctuations, can impact the cost of galvanized bar grating. Staying informed on these market trends is crucial, as they can dictate when to purchase for cost-efficiency. Partnering with reputable suppliers who provide pricing transparency and market insights can build a smarter purchasing strategy. Installation costs are often overlooked but are influential in the overall cost structure. While the material cost is essential, the ease of installation and the type of fixation used (e.g., welding or bolting) determine the labor costs involved. Choosing a system that aligns with the skills available within an organization can optimize total expenses. To enhance the purchase experience, consider certifications and quality verification of the grating, which adds a layer of trust and assurance in product longevity. Recognized certifications ensure that the grating meets industry standards, ultimately providing cost savings by reducing maintenance and replacement needs. In summary, the cost of galvanized bar grating is mulled over by factors like material choice, galvanization method, panel specifications, and market conditions, alongside transportation and installation logistics. By examining each element thoroughly, businesses can make well-informed decisions, optimizing both immediate expenses and long-term investment returns. Trustworthy suppliers and up-to-date market intelligence are instrumental in navigating the complexities of purchasing galvanized bar grating effectively.

Additionally, current market conditions, including raw material prices and demand fluctuations, can impact the cost of galvanized bar grating. Staying informed on these market trends is crucial, as they can dictate when to purchase for cost-efficiency. Partnering with reputable suppliers who provide pricing transparency and market insights can build a smarter purchasing strategy. Installation costs are often overlooked but are influential in the overall cost structure. While the material cost is essential, the ease of installation and the type of fixation used (e.g., welding or bolting) determine the labor costs involved. Choosing a system that aligns with the skills available within an organization can optimize total expenses. To enhance the purchase experience, consider certifications and quality verification of the grating, which adds a layer of trust and assurance in product longevity. Recognized certifications ensure that the grating meets industry standards, ultimately providing cost savings by reducing maintenance and replacement needs. In summary, the cost of galvanized bar grating is mulled over by factors like material choice, galvanization method, panel specifications, and market conditions, alongside transportation and installation logistics. By examining each element thoroughly, businesses can make well-informed decisions, optimizing both immediate expenses and long-term investment returns. Trustworthy suppliers and up-to-date market intelligence are instrumental in navigating the complexities of purchasing galvanized bar grating effectively.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024