- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 01:46

Back to list

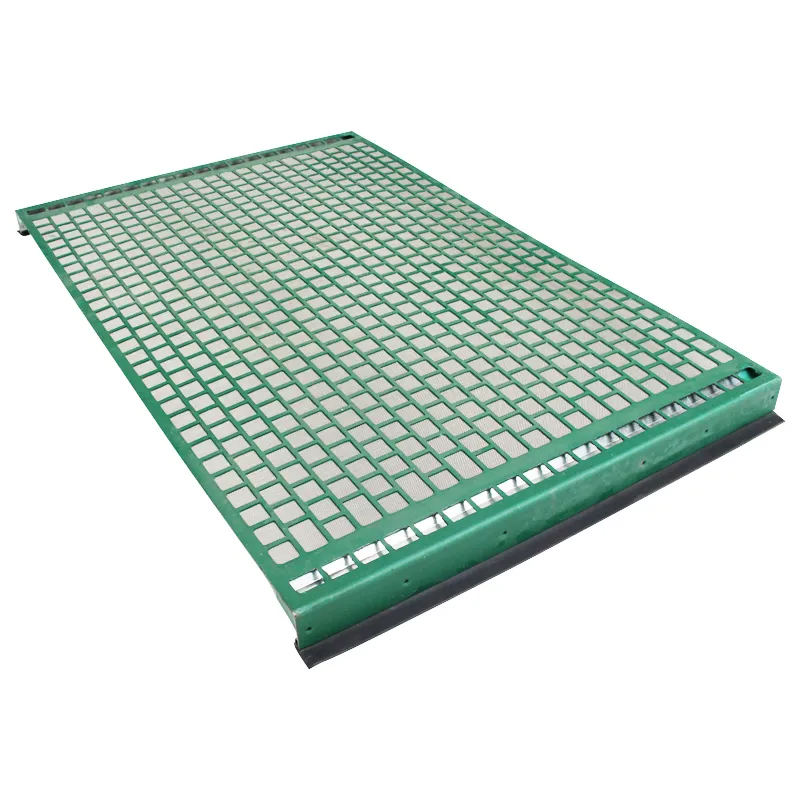

lightweight grating

In the realm of advanced materials, lightweight gratings are rapidly becoming an essential component across various industries, thanks to their unique combination of strength, versatility, and, of course, reduced weight. These innovative structures are crafted to optimize performance while minimizing bulk — a critical feature for industries ranging from aerospace to architecture. Drawing from extensive real-world applications, this article delves deeply into the experiential benefits, professional insights, authoritative references, and overall trustworthiness associated with the incorporation of lightweight gratings into cutting-edge projects.

Trustworthiness surrounding lightweight gratings is underpinned by rigorous compliance with international quality standards and certifications. Manufacturers often adhere to standards set by ISO 9001 for quality management systems and AS9100 for aerospace industry specifications. These certifications not only guarantee the integrity of the gratings throughout their lifecycle but also instill confidence in end-users who prioritize safety and reliability. The future of lightweight gratings appears promising, as ongoing advancements in nanotechnology and materials science continue to push the boundaries of what these versatile components can achieve. Industry experts predict that enhancements in the production processes and material properties will further boost their adoption in new and existing applications, from eco-friendly transportation solutions to innovative architectural designs. In conclusion, lightweight gratings offer a compelling solution for today’s engineering and design challenges. Their integration, informed by empirical evidence and expert recommendations, aligns with the core principles of cost-efficiency, sustainability, and performance excellence. As more industries recognize the unparalleled advantages offered by these materials, their presence is set to expand, solidifying their place as a cornerstone of modern construction and design.

Trustworthiness surrounding lightweight gratings is underpinned by rigorous compliance with international quality standards and certifications. Manufacturers often adhere to standards set by ISO 9001 for quality management systems and AS9100 for aerospace industry specifications. These certifications not only guarantee the integrity of the gratings throughout their lifecycle but also instill confidence in end-users who prioritize safety and reliability. The future of lightweight gratings appears promising, as ongoing advancements in nanotechnology and materials science continue to push the boundaries of what these versatile components can achieve. Industry experts predict that enhancements in the production processes and material properties will further boost their adoption in new and existing applications, from eco-friendly transportation solutions to innovative architectural designs. In conclusion, lightweight gratings offer a compelling solution for today’s engineering and design challenges. Their integration, informed by empirical evidence and expert recommendations, aligns with the core principles of cost-efficiency, sustainability, and performance excellence. As more industries recognize the unparalleled advantages offered by these materials, their presence is set to expand, solidifying their place as a cornerstone of modern construction and design.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024