- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 01:26

Back to list

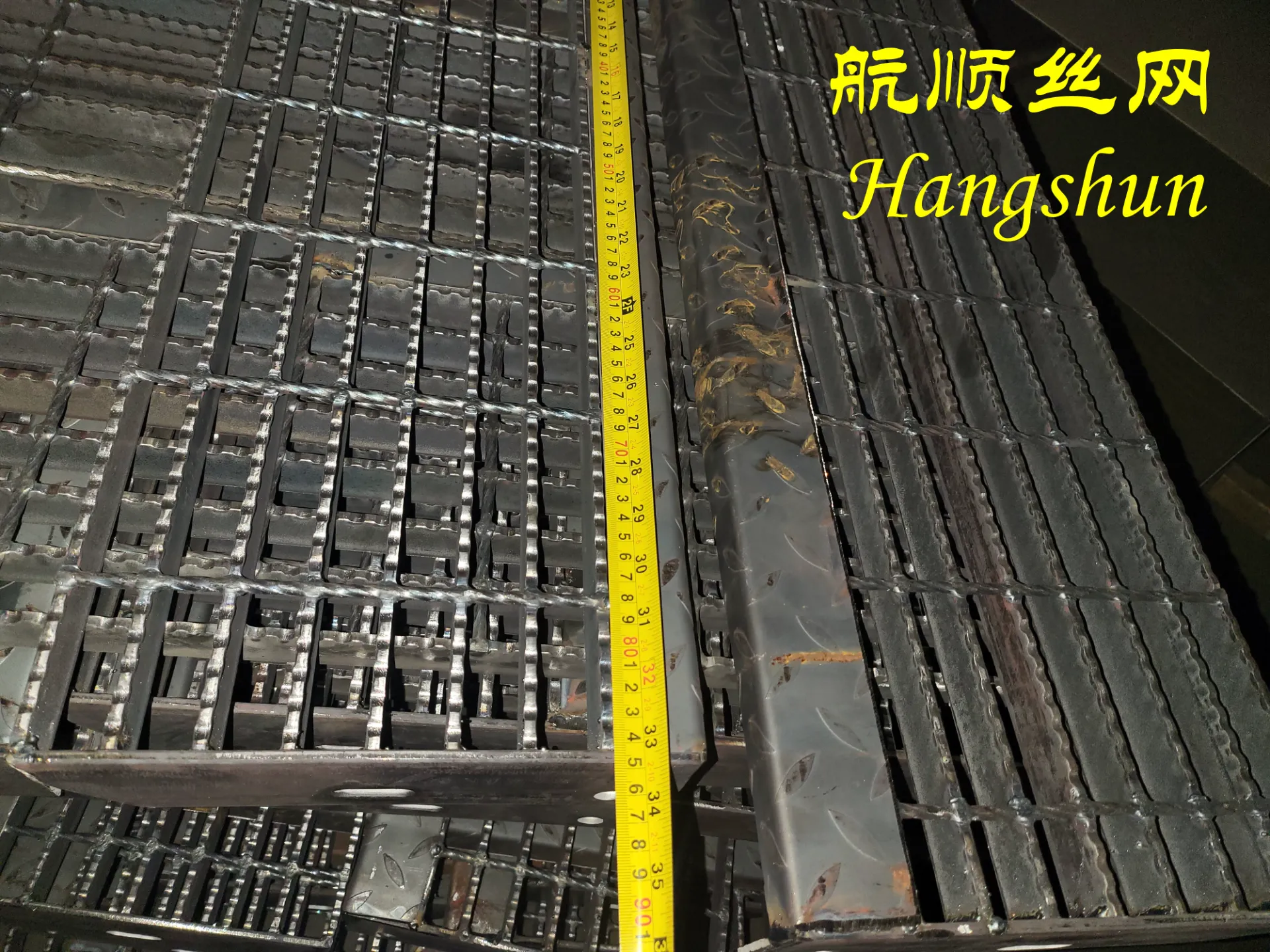

light duty grating

In today's competitive market, industries are constantly seeking out effective ways to optimize their operations while maintaining safety and functionality standards. One product that has continually proven to be indispensable in the realm of industrial flooring and platforms is light duty grating. This versatile material not only offers a multitude of benefits but also stands out due to its unrivaled design when considering practicality and sustainability.

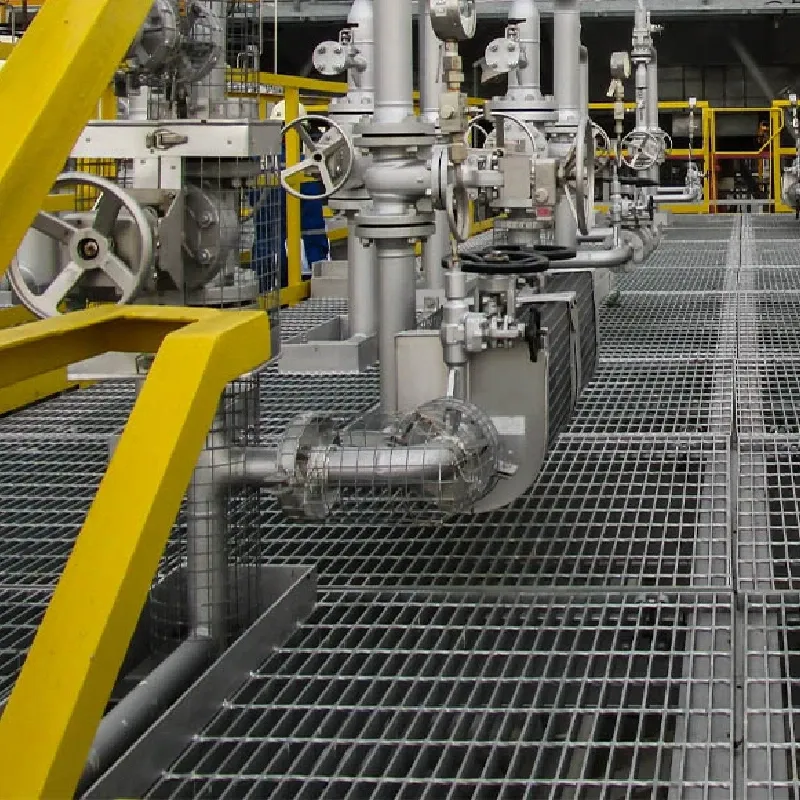

Trustworthiness is another essential factor that distinguishes light duty grating from its competitors. Manufacturers of such products prioritize transparency, offering comprehensive information and support throughout the product lifecycle. This includes clear installation instructions, maintenance guidelines, and after-sales service, ensuring that customers are fully supported from purchase through to application. Furthermore, their commitment to using sustainable materials not only improves product longevity but also demonstrates a dedication to an eco-friendly future, aligning with the growing consumer demand for sustainable industrial solutions. In terms of application, light duty grating is remarkably diverse, serving roles in walkways, mezzanines, drainage covers, stair treads, and more. Its open grid design facilitates easy drainage and airflow, preventing the accumulation of liquids and debris that could impair operations and pose safety risks. This feature is especially advantageous in sectors where cleanliness and hygiene are paramount, such as food processing and chemical industries. The future of light duty grating looks promising as industries continue to evolve and prioritize products that offer both safety and efficiency. It exemplifies how thoughtful design and material science can converge to solve real-world problems, setting benchmarks for innovation in industrial applications. As technology advances, we can anticipate even more refined versions of this grating, incorporating cutting-edge materials and smart features to further enhance their utility and functionality. In sum, light duty grating is a prime example of a product that successfully combines practicality with expert engineering. Its widespread acclaim and utilization across industries stand as a testament to its exceptional performance and versatility. When it comes to choosing a flooring or platform solution that is reliable, durable, and efficient, light duty grating is without a doubt a superior choice, offering benefits that extend far beyond its immediate functional uses.

Trustworthiness is another essential factor that distinguishes light duty grating from its competitors. Manufacturers of such products prioritize transparency, offering comprehensive information and support throughout the product lifecycle. This includes clear installation instructions, maintenance guidelines, and after-sales service, ensuring that customers are fully supported from purchase through to application. Furthermore, their commitment to using sustainable materials not only improves product longevity but also demonstrates a dedication to an eco-friendly future, aligning with the growing consumer demand for sustainable industrial solutions. In terms of application, light duty grating is remarkably diverse, serving roles in walkways, mezzanines, drainage covers, stair treads, and more. Its open grid design facilitates easy drainage and airflow, preventing the accumulation of liquids and debris that could impair operations and pose safety risks. This feature is especially advantageous in sectors where cleanliness and hygiene are paramount, such as food processing and chemical industries. The future of light duty grating looks promising as industries continue to evolve and prioritize products that offer both safety and efficiency. It exemplifies how thoughtful design and material science can converge to solve real-world problems, setting benchmarks for innovation in industrial applications. As technology advances, we can anticipate even more refined versions of this grating, incorporating cutting-edge materials and smart features to further enhance their utility and functionality. In sum, light duty grating is a prime example of a product that successfully combines practicality with expert engineering. Its widespread acclaim and utilization across industries stand as a testament to its exceptional performance and versatility. When it comes to choosing a flooring or platform solution that is reliable, durable, and efficient, light duty grating is without a doubt a superior choice, offering benefits that extend far beyond its immediate functional uses.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024