- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 30, 2025 04:52

Back to list

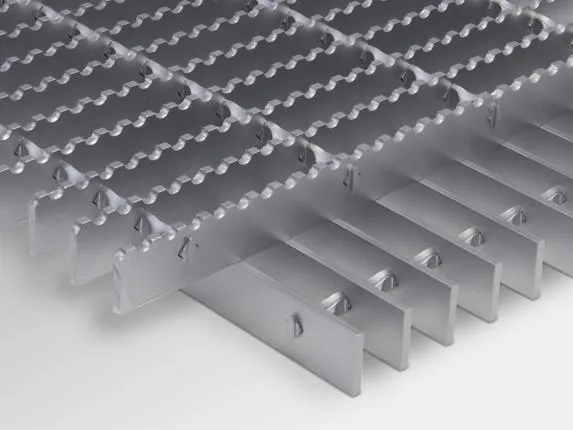

Press-Locked Steel Grating

Heavy-duty stainless steel grating is rapidly becoming the material of choice for a wide range of industrial and commercial applications. Boasting a blend of durability, strength, and resistance to corrosion, this type of grating is engineered to withstand the harshest environments and meet the strictest safety standards. In this in-depth exploration, we aim to delve into the qualities that make heavy-duty stainless steel grating indispensable in various sectors, backed by professional insight, authoritative information, and trustworthy data.

From an ecological perspective, heavy-duty stainless steel grating is an environmentally considerate choice. Being fully recyclable, it contributes to a sustainable lifecycle, supporting industries in their strategic moves towards green initiatives. As global emphasis on reducing carbon footprints grows, industries employing this material benefit from not only its performance but also its alignment with sustainability goals. Furthermore, the aesthetic appeal of stainless steel grating cannot be understated. Its sleek, modern look is adaptable for architectural designs, providing both functionality and an enhanced visual profile for buildings and infrastructures. The material's ability to maintain its appearance over many years without discolouration or rusting is invaluable for projects where aesthetic longevity is desired. Professionals seeking reliable information on stainless steel grating often turn to trusted sources such as the American Iron and Steel Institute (AISI) and the Specialty Steel Industry of North America (SSINA), which provide detailed specifications and usage guidelines. These authoritative bodies advocate for standards that ensure products meet industry benchmarks, giving you the confidence that what you're using is endorsed by experts in the field. In drawing from collective industry expertise, it’s clear that choosing heavy-duty stainless steel grating is a strategic decision supported by experiential evidence and authoritative consensus. For those vested in operations where the safety, durability, and quality of materials define success, investing in this grating type is both a practical and forward-looking move. With these insights, engineers, procurement specialists, and decision-makers are better positioned to leverage heavy-duty stainless steel grating in optimizing facility operations while aligning with contemporary trends in sustainability and design excellence. The investment not only secures reliable performance but also future-proofs infrastructure with a material that's stood the test of industrial evolution. As industries continue to embrace innovation, heavy-duty stainless steel grating stands out as a testament to that progress.

From an ecological perspective, heavy-duty stainless steel grating is an environmentally considerate choice. Being fully recyclable, it contributes to a sustainable lifecycle, supporting industries in their strategic moves towards green initiatives. As global emphasis on reducing carbon footprints grows, industries employing this material benefit from not only its performance but also its alignment with sustainability goals. Furthermore, the aesthetic appeal of stainless steel grating cannot be understated. Its sleek, modern look is adaptable for architectural designs, providing both functionality and an enhanced visual profile for buildings and infrastructures. The material's ability to maintain its appearance over many years without discolouration or rusting is invaluable for projects where aesthetic longevity is desired. Professionals seeking reliable information on stainless steel grating often turn to trusted sources such as the American Iron and Steel Institute (AISI) and the Specialty Steel Industry of North America (SSINA), which provide detailed specifications and usage guidelines. These authoritative bodies advocate for standards that ensure products meet industry benchmarks, giving you the confidence that what you're using is endorsed by experts in the field. In drawing from collective industry expertise, it’s clear that choosing heavy-duty stainless steel grating is a strategic decision supported by experiential evidence and authoritative consensus. For those vested in operations where the safety, durability, and quality of materials define success, investing in this grating type is both a practical and forward-looking move. With these insights, engineers, procurement specialists, and decision-makers are better positioned to leverage heavy-duty stainless steel grating in optimizing facility operations while aligning with contemporary trends in sustainability and design excellence. The investment not only secures reliable performance but also future-proofs infrastructure with a material that's stood the test of industrial evolution. As industries continue to embrace innovation, heavy-duty stainless steel grating stands out as a testament to that progress.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024