- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 28, 2025 01:45

Back to list

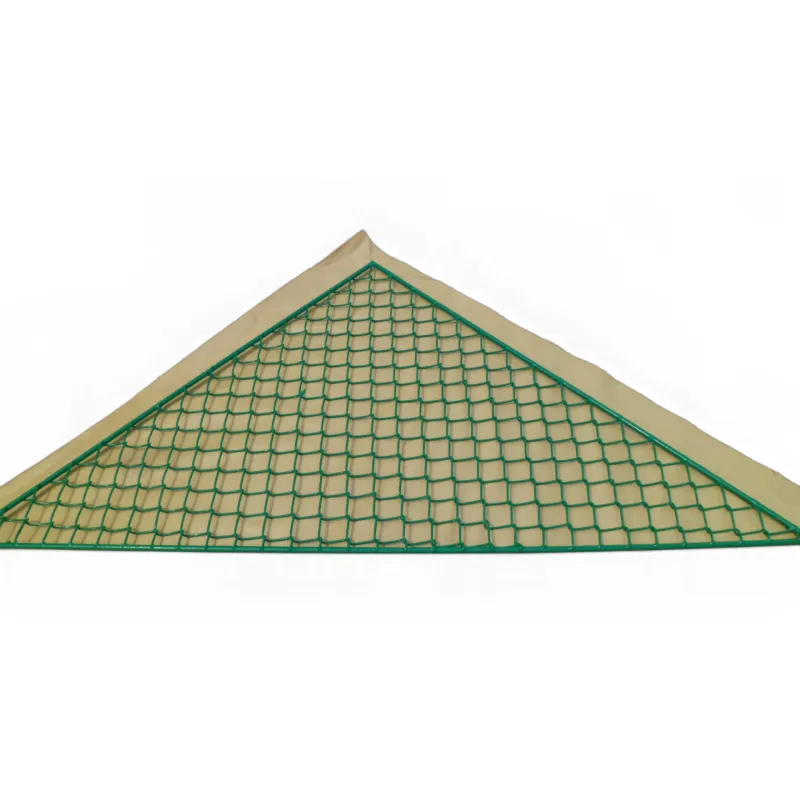

heavy duty gratings

Heavy duty gratings are an integral component in numerous industrial applications, remarkable for their robustness, reliability, and ability to support substantial loads. As industries continue to evolve, the need for resilient infrastructure has never been more pronounced. This article delves into the multifaceted advantages of heavy duty gratings, underscoring their unmatched utility in a wide spectrum of sectors.

Trustworthiness in the grating industry is built on decades of consistent performance and proven results. Case studies abound where the deployment of these gratings has led to tangible improvements in operational safety and workflow efficiency. Industries looking to invest in sustainable infrastructure solutions are often guided by the testimonials and documented benefits accrued from organizations that have efficiently integrated heavy duty gratings into their operations. Innovation continues to drive advancements in grating technology. Contemporary heavy duty gratings increasingly incorporate features such as anti-slip surfaces, enhanced drainage capabilities, and even aesthetic customization options. These innovations are particularly prevalent in sectors where both functionality and aesthetic considerations are paramount, such as architectural installations or public infrastructural projects. The environmental impact of industrial manufacturing has not been overlooked, and heavy duty gratings are no exception. Eco-friendly production practices are gaining traction, with manufacturers striving to minimize waste and reduce their carbon footprint. The choice of sustainable materials and efficient manufacturing processes reflect a broader industry shift towards ecological responsibility without compromising on product efficacy. In conclusion, heavy duty gratings stand as a testament to the innovative strides and commitment to quality within the industrial sector. Their unmatched ability to perform under the most demanding conditions, paired with a manufacturing pedigree steeped in expertise, positions them as a cornerstone of modern industrial infrastructure. Through continued innovation and commitment to sustainable practices, heavy duty gratings will undoubtedly maintain their pivotal role across diverse industry landscapes.

Trustworthiness in the grating industry is built on decades of consistent performance and proven results. Case studies abound where the deployment of these gratings has led to tangible improvements in operational safety and workflow efficiency. Industries looking to invest in sustainable infrastructure solutions are often guided by the testimonials and documented benefits accrued from organizations that have efficiently integrated heavy duty gratings into their operations. Innovation continues to drive advancements in grating technology. Contemporary heavy duty gratings increasingly incorporate features such as anti-slip surfaces, enhanced drainage capabilities, and even aesthetic customization options. These innovations are particularly prevalent in sectors where both functionality and aesthetic considerations are paramount, such as architectural installations or public infrastructural projects. The environmental impact of industrial manufacturing has not been overlooked, and heavy duty gratings are no exception. Eco-friendly production practices are gaining traction, with manufacturers striving to minimize waste and reduce their carbon footprint. The choice of sustainable materials and efficient manufacturing processes reflect a broader industry shift towards ecological responsibility without compromising on product efficacy. In conclusion, heavy duty gratings stand as a testament to the innovative strides and commitment to quality within the industrial sector. Their unmatched ability to perform under the most demanding conditions, paired with a manufacturing pedigree steeped in expertise, positions them as a cornerstone of modern industrial infrastructure. Through continued innovation and commitment to sustainable practices, heavy duty gratings will undoubtedly maintain their pivotal role across diverse industry landscapes.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024