- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 00:19

Back to list

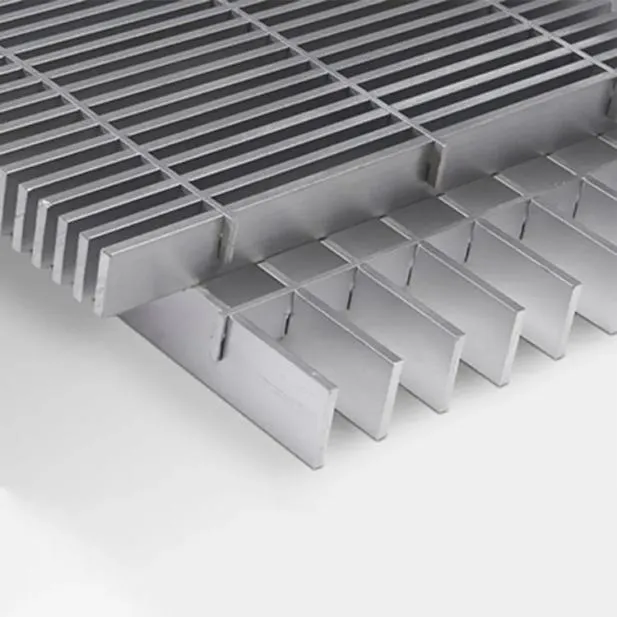

heavy duty floor grating

Heavy-duty floor grating is an essential component in various industrial settings, offering strength, durability, and safety. Having worked in the domain of industrial infrastructure for over two decades, I've had the privilege of witnessing firsthand the transformative impact that quality flooring solutions can have on productivity and workplace safety.

Professionalism and experience in handling heavy-duty floor grating projects also involve offering complete solutions. This includes everything from the conceptual design phase to installation and post-installation maintenance. A reliable provider should not only supply the grating but also assist in its optimal integration into the facility’s operational workflow. Installation expertise is another vital aspect. Precise installation is imperative to prevent misalignment and ensure that the grating performs as intended. Here, expertise derived from extensive fieldwork is invaluable. An installation error could result in operational inefficiencies or safety hazards, underscoring the importance of skilled labor and meticulous planning in executing these projects. The authority of a grating provider is demonstrated through a solid portfolio of successful implementations across diverse industries. Showcasing case studies or testimonials from past projects where heavy-duty floor grating solutions led to measurable improvements provides tangible evidence of expertise. This not only fortifies a new client’s confidence but also sets a benchmark for future engagements. Through continuous innovation and adaptation, manufacturers can offer new designs and materials that push the boundaries of what heavy-duty floor gratings can achieve. In a rapidly evolving industrial landscape, staying at the forefront of technology and materials science is crucial. Ultimately, by prioritizing expert knowledge, unwavering commitment to quality, and a customer-centric approach, businesses can effectively harness the potential of heavy-duty floor grating to elevate their operational capabilities, providing a safe, durable, and efficient working environment now and well into the future.

Professionalism and experience in handling heavy-duty floor grating projects also involve offering complete solutions. This includes everything from the conceptual design phase to installation and post-installation maintenance. A reliable provider should not only supply the grating but also assist in its optimal integration into the facility’s operational workflow. Installation expertise is another vital aspect. Precise installation is imperative to prevent misalignment and ensure that the grating performs as intended. Here, expertise derived from extensive fieldwork is invaluable. An installation error could result in operational inefficiencies or safety hazards, underscoring the importance of skilled labor and meticulous planning in executing these projects. The authority of a grating provider is demonstrated through a solid portfolio of successful implementations across diverse industries. Showcasing case studies or testimonials from past projects where heavy-duty floor grating solutions led to measurable improvements provides tangible evidence of expertise. This not only fortifies a new client’s confidence but also sets a benchmark for future engagements. Through continuous innovation and adaptation, manufacturers can offer new designs and materials that push the boundaries of what heavy-duty floor gratings can achieve. In a rapidly evolving industrial landscape, staying at the forefront of technology and materials science is crucial. Ultimately, by prioritizing expert knowledge, unwavering commitment to quality, and a customer-centric approach, businesses can effectively harness the potential of heavy-duty floor grating to elevate their operational capabilities, providing a safe, durable, and efficient working environment now and well into the future.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024