- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 23:39

Back to list

grating types

Exploring the Diverse World of Grating Types An In-Depth Guide

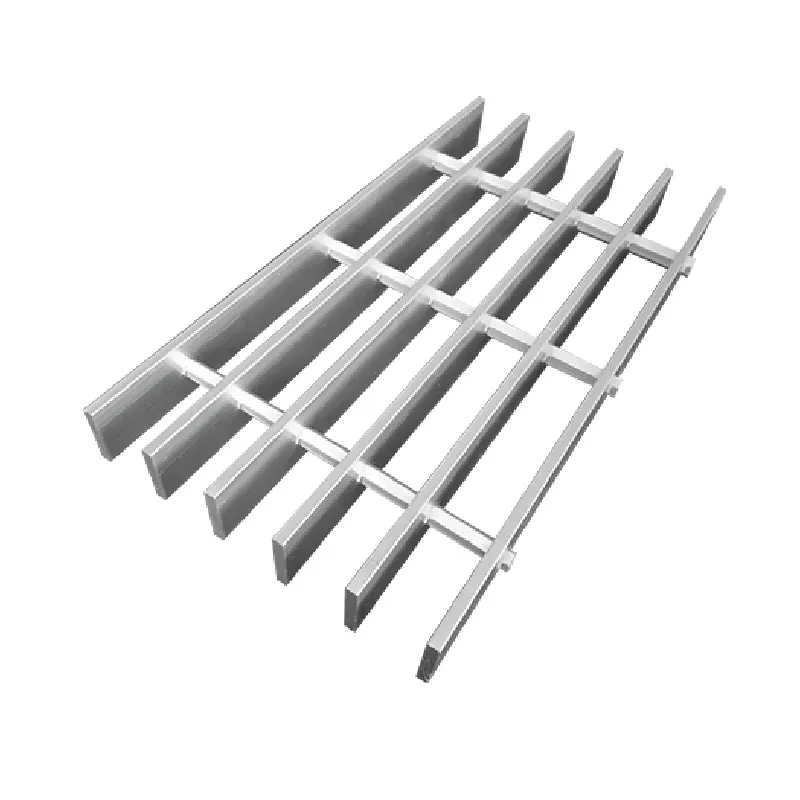

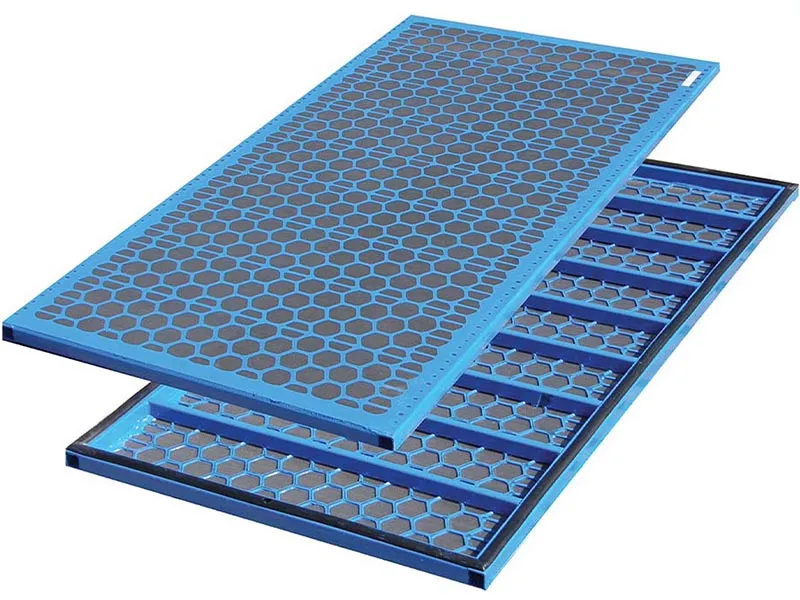

5. Pultruded Grating Pultruded grating is a type of FRP grating produced through the pultrusion process, which aligns reinforcements in a linear fashion. This method results in gratings that offer exceptional strength, often comparable to steel, but without the weight or maintenance demands. Pultruded grating is typically employed in environments requiring high load-bearing capacity without the risk of corrosion. 6. Stainless Steel Grating When hygiene is a top priority, stainless steel grating is the material of choice. Its anti-corrosive nature and ease of cleaning make it suitable for food and beverage facilities, pharmaceuticals, and laboratories. Stainless steel grating’s aesthetic and structural qualities also make it an attractive option for modern architectural designs. 7. Bar Grating Bar grating is a versatile product suitable for both commercial and industrial applications. It’s made by joining a series of load-bearing bars to cross bars, creating a grid that supports significant loads. Used in catwalks, trenches, and mezzanines, bar grating offers excellent drainage and air circulation while maintaining structural performance. Choosing the Right Grating Type Selecting the most suitable type involves assessing several factors the environment in which the grating will be used, the physical demands of the application, aesthetic considerations, and budget constraints. Each grating material offers specific advantages, and understanding these can prevent costly mistakes and enhance productivity and safety. For companies prioritizing environmental considerations, FRP and aluminum gratings offer sustainable benefits due to their recyclability and lower environmental impact during manufacture and use. Meanwhile, industries where chemical exposure is routine might favor FRP or stainless steel for their innate resistance to corrosion and easy maintenance. Gratings are foundational components that improve safety, increase operational efficiency, and contribute aesthetically to spaces. As experts in the field, understanding these differences and applications enhances decision-making, ensuring the right selections that drive innovation and operational excellence. Grating solutions are not merely construction components; they are integral to infrastructure, safety, and sustainability in modern design and industry.

5. Pultruded Grating Pultruded grating is a type of FRP grating produced through the pultrusion process, which aligns reinforcements in a linear fashion. This method results in gratings that offer exceptional strength, often comparable to steel, but without the weight or maintenance demands. Pultruded grating is typically employed in environments requiring high load-bearing capacity without the risk of corrosion. 6. Stainless Steel Grating When hygiene is a top priority, stainless steel grating is the material of choice. Its anti-corrosive nature and ease of cleaning make it suitable for food and beverage facilities, pharmaceuticals, and laboratories. Stainless steel grating’s aesthetic and structural qualities also make it an attractive option for modern architectural designs. 7. Bar Grating Bar grating is a versatile product suitable for both commercial and industrial applications. It’s made by joining a series of load-bearing bars to cross bars, creating a grid that supports significant loads. Used in catwalks, trenches, and mezzanines, bar grating offers excellent drainage and air circulation while maintaining structural performance. Choosing the Right Grating Type Selecting the most suitable type involves assessing several factors the environment in which the grating will be used, the physical demands of the application, aesthetic considerations, and budget constraints. Each grating material offers specific advantages, and understanding these can prevent costly mistakes and enhance productivity and safety. For companies prioritizing environmental considerations, FRP and aluminum gratings offer sustainable benefits due to their recyclability and lower environmental impact during manufacture and use. Meanwhile, industries where chemical exposure is routine might favor FRP or stainless steel for their innate resistance to corrosion and easy maintenance. Gratings are foundational components that improve safety, increase operational efficiency, and contribute aesthetically to spaces. As experts in the field, understanding these differences and applications enhances decision-making, ensuring the right selections that drive innovation and operational excellence. Grating solutions are not merely construction components; they are integral to infrastructure, safety, and sustainability in modern design and industry.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024