- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 09:44

Back to list

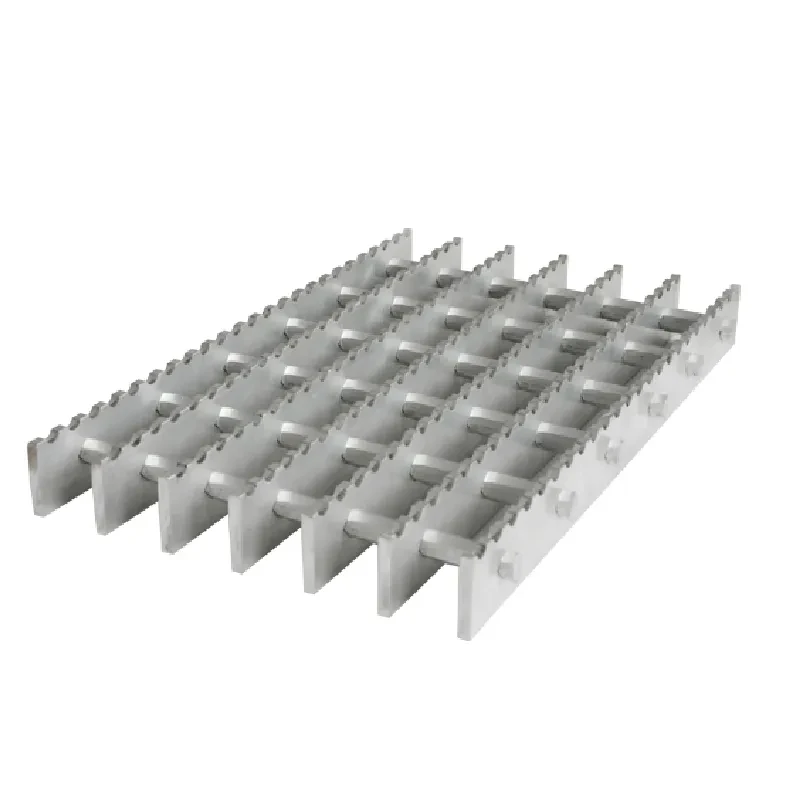

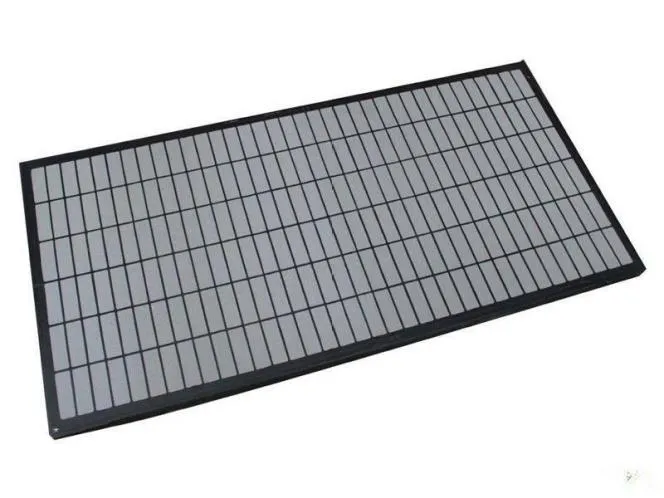

grating price

Understanding the world of industrial materials can often be complex, especially when it comes to specifying the correct types for unique applications. One such material that has seen a considerable surge in demand is grating. Navigating the grating price landscape can be challenging, but it is essential for making informed purchasing decisions and ensuring value.

Furthermore, grating specifications — including load ratings, bar spacing, and thickness — can greatly impact final pricing. Projects requiring higher load ratings necessitate denser, thicker grating options, inevitably leading to increased material costs. Conversely, spaces with lighter foot traffic may benefit from thinner, less expensive grating options. Supply chain considerations, including raw material availability and logistics, can also influence grating prices. Global events, such as trade tariffs or shipping disruptions, have the potential to drive prices up unexpectedly. Thus, maintaining strong relationships with reputable suppliers who can navigate these variables, providing consistent and competitive pricing, is crucial. Beyond these factors, environmental considerations are increasingly influencing purchasing decisions. Sustainable production processes and materials that adhere to environmental standards can slightly increase costs but often result in long-term savings by enhancing site safety and reducing ecological impact. Finally, ensuring the authenticity of the grating supplier is imperative. Trustworthiness in this sector is measured by adherence to industry standards, transparency in production processes, and a solid track record of quality assurance. Choosing a supplier that exemplifies these attributes can mitigate risks associated with inferior quality products that might compromise structural integrity. As an informed buyer, recognizing these multifaceted aspects provides a competitive edge in navigating the grating price landscape. By understanding how material choices, manufacturing methods, and market conditions interplay to influence pricing, companies can effectively meet their project requirements while optimizing budgets. In a market as dynamic as this, staying informed and maintaining a network of reliable suppliers ensures both the success and safety of industrial applications.

Furthermore, grating specifications — including load ratings, bar spacing, and thickness — can greatly impact final pricing. Projects requiring higher load ratings necessitate denser, thicker grating options, inevitably leading to increased material costs. Conversely, spaces with lighter foot traffic may benefit from thinner, less expensive grating options. Supply chain considerations, including raw material availability and logistics, can also influence grating prices. Global events, such as trade tariffs or shipping disruptions, have the potential to drive prices up unexpectedly. Thus, maintaining strong relationships with reputable suppliers who can navigate these variables, providing consistent and competitive pricing, is crucial. Beyond these factors, environmental considerations are increasingly influencing purchasing decisions. Sustainable production processes and materials that adhere to environmental standards can slightly increase costs but often result in long-term savings by enhancing site safety and reducing ecological impact. Finally, ensuring the authenticity of the grating supplier is imperative. Trustworthiness in this sector is measured by adherence to industry standards, transparency in production processes, and a solid track record of quality assurance. Choosing a supplier that exemplifies these attributes can mitigate risks associated with inferior quality products that might compromise structural integrity. As an informed buyer, recognizing these multifaceted aspects provides a competitive edge in navigating the grating price landscape. By understanding how material choices, manufacturing methods, and market conditions interplay to influence pricing, companies can effectively meet their project requirements while optimizing budgets. In a market as dynamic as this, staying informed and maintaining a network of reliable suppliers ensures both the success and safety of industrial applications.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024