- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 10:19

Back to list

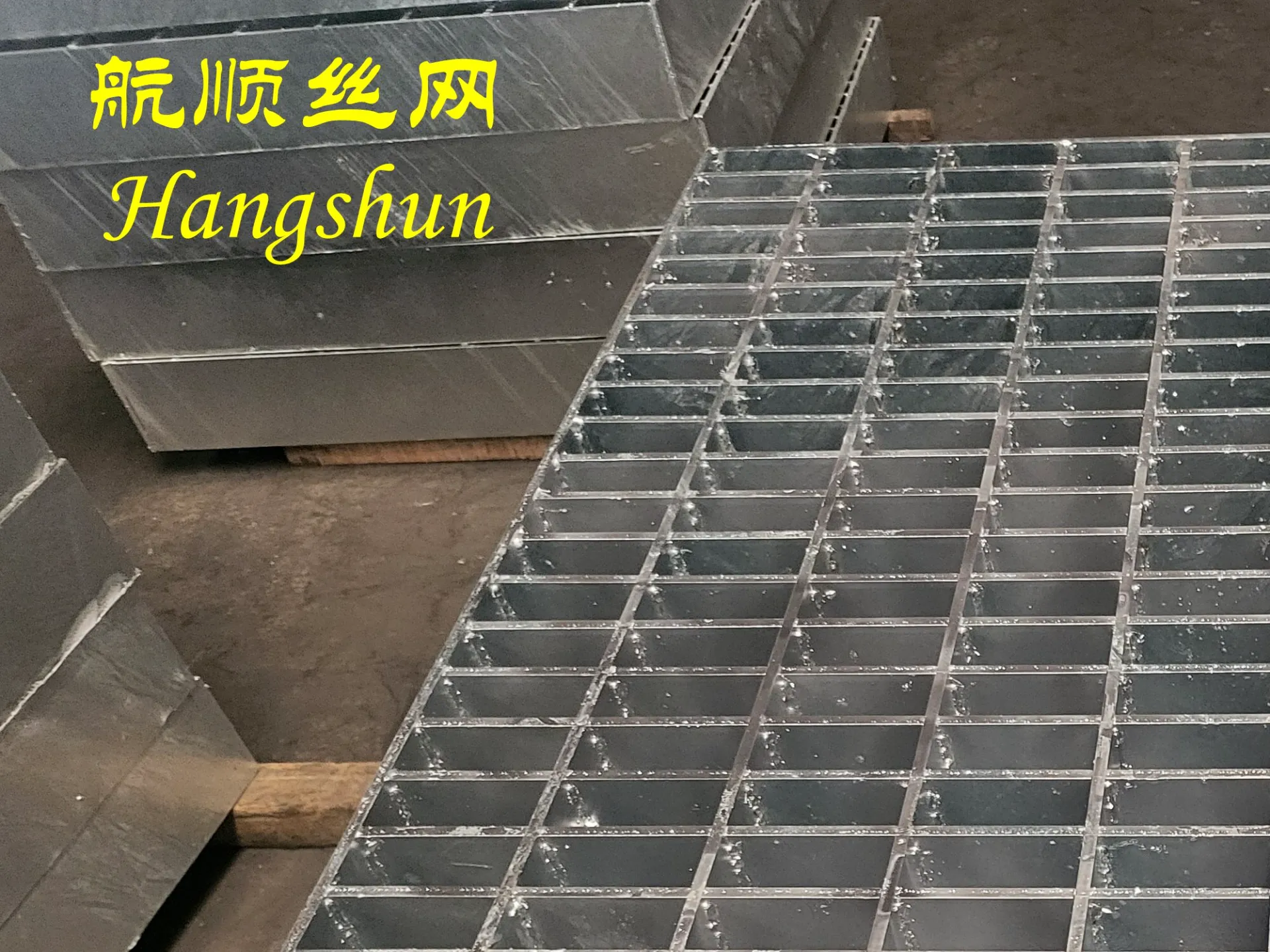

bar grating prices

Navigating the landscape of bar grating prices can be an intricate task, especially for those who rely heavily on this indispensable product across various industries. As a tool that combines functionality with endurance, bar grating is at the core of many infrastructure projects, from industrial flooring to bridges and walkways. Understanding the nuances behind the pricing of bar gratings not only helps in budgeting but also ensures that one gets the right product suited to their specific needs.

Customization further influences pricing. Standard grating panels come at lower costs due to mass production efficiencies, but many clients require customization to meet specific dimensions or load-bearing requirements. Tailored solutions often involve additional costs, encapsulating design, cutting, and finishing services to perfectly fit project needs. Furthermore, the geographic location of suppliers and logistics considerations can also sway bar grating prices. Transportation costs, import duties, and regulatory compliances add layers of complexity to pricing structures, emphasizing the importance of negotiating with local suppliers when feasible. Local sourcing not only reduces transport expenses but also supports economic sustainability by fostering regional businesses. In this context, partnerships with reputable suppliers become invaluable. Trustworthy suppliers bring transparency to the table, ensuring no hidden costs accrue post-purchasing. Their experience and expertise in the field help deliver product assurance and adherences to safety standards and certifications, dealing not only in products but peace of mind. Lastly, businesses should also consider the long-term investment aspect when evaluating bar grating costs. Factoring in the total cost of ownership, including installation, lifespan, maintenance, and depreciation, provides a holistic understanding of expense versus value. A higher upfront cost for superior materials or design might yield better economic returns over time, reducing the need for frequent replacements or repairs. In summary, navigating bar grating prices requires a nuanced understanding of material properties, manufacturing methods, customization needs, location factors, and supplier reliability. The insights gained through exploring these elements empower businesses to make informed purchases that align with their objectives, ensuring safety, efficiency, and financial prudence in utilizing bar gratings across various applications.

Customization further influences pricing. Standard grating panels come at lower costs due to mass production efficiencies, but many clients require customization to meet specific dimensions or load-bearing requirements. Tailored solutions often involve additional costs, encapsulating design, cutting, and finishing services to perfectly fit project needs. Furthermore, the geographic location of suppliers and logistics considerations can also sway bar grating prices. Transportation costs, import duties, and regulatory compliances add layers of complexity to pricing structures, emphasizing the importance of negotiating with local suppliers when feasible. Local sourcing not only reduces transport expenses but also supports economic sustainability by fostering regional businesses. In this context, partnerships with reputable suppliers become invaluable. Trustworthy suppliers bring transparency to the table, ensuring no hidden costs accrue post-purchasing. Their experience and expertise in the field help deliver product assurance and adherences to safety standards and certifications, dealing not only in products but peace of mind. Lastly, businesses should also consider the long-term investment aspect when evaluating bar grating costs. Factoring in the total cost of ownership, including installation, lifespan, maintenance, and depreciation, provides a holistic understanding of expense versus value. A higher upfront cost for superior materials or design might yield better economic returns over time, reducing the need for frequent replacements or repairs. In summary, navigating bar grating prices requires a nuanced understanding of material properties, manufacturing methods, customization needs, location factors, and supplier reliability. The insights gained through exploring these elements empower businesses to make informed purchases that align with their objectives, ensuring safety, efficiency, and financial prudence in utilizing bar gratings across various applications.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024