- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 19:44

Back to list

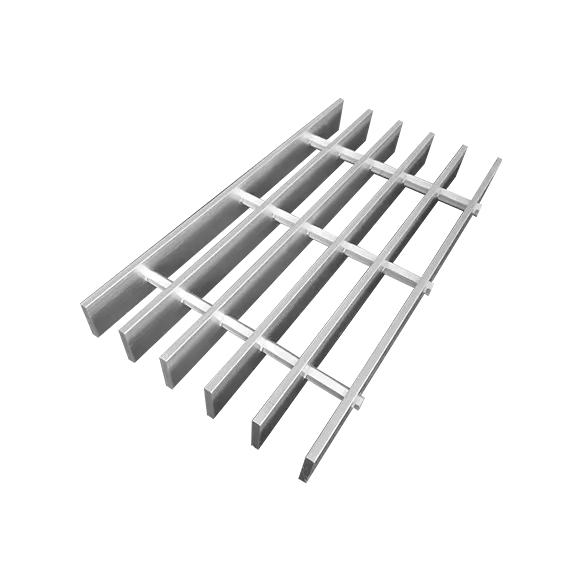

Steel Grating

Grating hot dip galvanized products have been a staple in industrial applications for decades, but understanding their full potential requires a deep dive into their unique attributes and benefits. Hot dip galvanizing is a process wherein metallic surfaces are coated with a layer of zinc to prevent corrosion. This robust treatment is particularly vital for grating, which is extensively used in environments susceptible to corrosion, such as industrial, marine, and outdoor settings.

Authoritativeness is another critical aspect that grating hot dip galvanized products hold, especially in sectors such as mining, oil and gas, and power generation. Industrial standards often necessitate materials that can tolerate extreme stress and exposure, and these galvanized gratings meet or surpass these rigorous requirements. Industry certification bodies often endorse these products, citing their reliability and effectiveness under extreme conditions. On the front of trustworthiness, the environmental benefits associated with hot dip galvanizing cannot be overstated. Zinc is a natural element and an essential component of the Earth’s crust. Its application in hot dip galvanizing is done under stringent environmental guidelines, ensuring no undue harm to the ecosystem. Furthermore, galvanized products are recyclable, supporting sustainable practices that modern industries are increasingly adopting. In considering the total lifecycle costs of industrial materials, grating hot dip galvanized products provide a superior return on investment. The initial costs are easily offset by the longevity and reduced maintenance these products require. Companies prioritizing long-term operational efficiency view these products as invaluable assets in their infrastructure. For those seeking to understand the real-world effectiveness of hot dip galvanized grating, numerous case studies demonstrate their resilience. Installations in coastal power plants, chemical factories, and offshore oil rigs have consistently shown the reliability of these products in resisting corrosion and maintaining structural integrity over decades. Users repeatedly report minimal issues and express satisfaction with the durability and performance even in the most demanding environments. As we continue to navigate the complexities of industrial requirements, the role of specialized materials has never been more critical. With proven performance, backed by scientific principles and rigorous testing, grating hot dip galvanized products offer a safe, sustainable, and financially sound choice for industries worldwide. Their unmatched performance and the assurance of quality through extensive research and development bolster their position as an industry leader. Investing in these products signifies a commitment to quality and operational excellence, a choice that promises to pay dividends in durability, safety, and cost-effectiveness.

Authoritativeness is another critical aspect that grating hot dip galvanized products hold, especially in sectors such as mining, oil and gas, and power generation. Industrial standards often necessitate materials that can tolerate extreme stress and exposure, and these galvanized gratings meet or surpass these rigorous requirements. Industry certification bodies often endorse these products, citing their reliability and effectiveness under extreme conditions. On the front of trustworthiness, the environmental benefits associated with hot dip galvanizing cannot be overstated. Zinc is a natural element and an essential component of the Earth’s crust. Its application in hot dip galvanizing is done under stringent environmental guidelines, ensuring no undue harm to the ecosystem. Furthermore, galvanized products are recyclable, supporting sustainable practices that modern industries are increasingly adopting. In considering the total lifecycle costs of industrial materials, grating hot dip galvanized products provide a superior return on investment. The initial costs are easily offset by the longevity and reduced maintenance these products require. Companies prioritizing long-term operational efficiency view these products as invaluable assets in their infrastructure. For those seeking to understand the real-world effectiveness of hot dip galvanized grating, numerous case studies demonstrate their resilience. Installations in coastal power plants, chemical factories, and offshore oil rigs have consistently shown the reliability of these products in resisting corrosion and maintaining structural integrity over decades. Users repeatedly report minimal issues and express satisfaction with the durability and performance even in the most demanding environments. As we continue to navigate the complexities of industrial requirements, the role of specialized materials has never been more critical. With proven performance, backed by scientific principles and rigorous testing, grating hot dip galvanized products offer a safe, sustainable, and financially sound choice for industries worldwide. Their unmatched performance and the assurance of quality through extensive research and development bolster their position as an industry leader. Investing in these products signifies a commitment to quality and operational excellence, a choice that promises to pay dividends in durability, safety, and cost-effectiveness.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024