- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 20:11

Back to list

Steel Grating

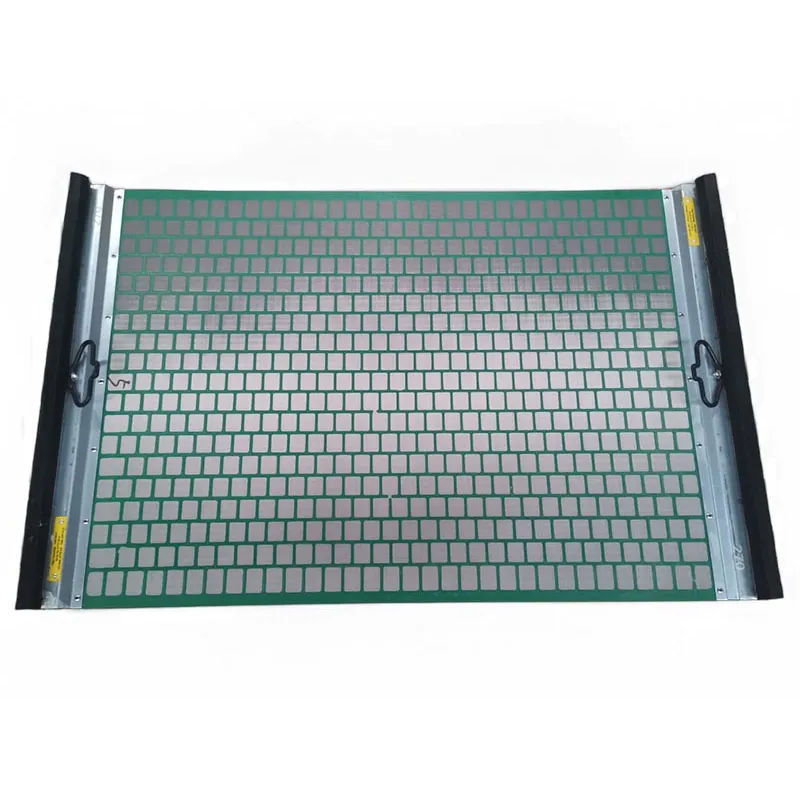

Exploring the World of Galvanised Walkway Panels An Expert Insight

The importance of selecting high-quality galvanised walkway panels cannot be stressed enough. It is critical for supplier credentials to be thoroughly vetted, ensuring compliance with international safety standards and environmental regulations. A reputable supplier should be able to provide comprehensive documentation verifying the quality and sourcing of their raw materials. Additionally, customer reviews and case studies provide valuable insights into the product’s performance across various applications. Engaging with suppliers who offer rigorous testing and quality assurance processes is imperative. This not only enhances trustworthiness but also supports informed decision-making for engineers and project managers. Innovations and Future Trends As industries push toward more sustainable practices, emerging trends in galvanised walkway panels focus on eco-friendly manufacturing processes. The development of more efficient galvanisation methods that reduce energy consumption and greenhouse gas emissions is underway. Simultaneously, advanced coatings are being researched to further enhance the anticorrosive properties without compromising environmental safety. The integration of technology with these panels is also anticipated. Smart panels, embedded with sensors to gauge environmental and load conditions, could soon revolutionise industrial safety standards. This innovation promises to offer real-time data and alerts, enabling preemptive maintenance actions and optimising project performance. Authoritative Best Practices To optimise the use of galvanised walkway panels, it is essential to adhere to best practices in their installation and maintenance. Proper inspection protocols should be in place to assess wear and tear, despite the product's renowned durability. Educating the workforce on the correct handling and placement techniques further extends the panels' service life. Consulting with structural engineers early in the project design phase ensures that the selected panels align with the specific load-bearing and environmental requirements of the site. It is also advisable to integrate routine cleaning schedules to prevent build-up of debris or substances that could potentially undermine the slip-resistant surface. In conclusion, galvanised walkway panels embody a confluence of safety, efficiency, and sustainability that is critical across numerous industrial applications. Their adoption signifies a commitment to quality and reliability, making these an essential consideration in any comprehensive safety and infrastructure strategy.

The importance of selecting high-quality galvanised walkway panels cannot be stressed enough. It is critical for supplier credentials to be thoroughly vetted, ensuring compliance with international safety standards and environmental regulations. A reputable supplier should be able to provide comprehensive documentation verifying the quality and sourcing of their raw materials. Additionally, customer reviews and case studies provide valuable insights into the product’s performance across various applications. Engaging with suppliers who offer rigorous testing and quality assurance processes is imperative. This not only enhances trustworthiness but also supports informed decision-making for engineers and project managers. Innovations and Future Trends As industries push toward more sustainable practices, emerging trends in galvanised walkway panels focus on eco-friendly manufacturing processes. The development of more efficient galvanisation methods that reduce energy consumption and greenhouse gas emissions is underway. Simultaneously, advanced coatings are being researched to further enhance the anticorrosive properties without compromising environmental safety. The integration of technology with these panels is also anticipated. Smart panels, embedded with sensors to gauge environmental and load conditions, could soon revolutionise industrial safety standards. This innovation promises to offer real-time data and alerts, enabling preemptive maintenance actions and optimising project performance. Authoritative Best Practices To optimise the use of galvanised walkway panels, it is essential to adhere to best practices in their installation and maintenance. Proper inspection protocols should be in place to assess wear and tear, despite the product's renowned durability. Educating the workforce on the correct handling and placement techniques further extends the panels' service life. Consulting with structural engineers early in the project design phase ensures that the selected panels align with the specific load-bearing and environmental requirements of the site. It is also advisable to integrate routine cleaning schedules to prevent build-up of debris or substances that could potentially undermine the slip-resistant surface. In conclusion, galvanised walkway panels embody a confluence of safety, efficiency, and sustainability that is critical across numerous industrial applications. Their adoption signifies a commitment to quality and reliability, making these an essential consideration in any comprehensive safety and infrastructure strategy.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024