- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 03, 2025 00:55

Back to list

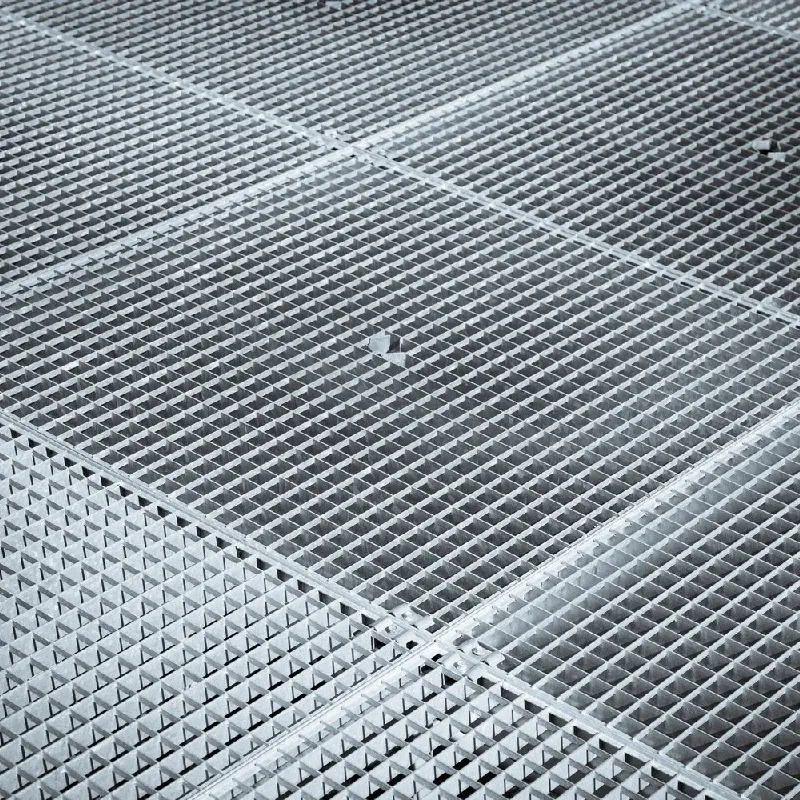

galvanized walkway grating

Enhancing both safety and functionality, galvanized walkway grating is an essential component in industrial, commercial, and even residential settings. These gratings are renowned for their strength, durability, and resistance to environmental factors, making them an optimal choice for various applications, such as walkways, platforms, and stair treads.

Maintenance of galvanized walkway grating is relatively straightforward, thanks to its protective zinc coating, which diminishes the frequency of upkeep activities. The surface naturally resists dirt and grime build-up, requiring only periodic cleaning to maintain its optimal condition. This ease of maintenance not only reduces operational costs but also ensures that the grating retains its aesthetic appeal and functional integrity years after installation. Environmental considerations also play a crucial role in the selection of galvanized walkway grating. The galvanizing process itself is environmentally friendly, with zinc being fully recyclable and less energy-intensive than other protective coatings. This eco-conscious element of the grating aligns with sustainable practices, allowing companies to meet green building standards and certifications. In terms of safety, galvanized walkway grating offers exceptional slip resistance, which is crucial in preventing accidents and ensuring the safety of workers and pedestrians. The grating's serrated edges provide added grip, making it suitable for both dry and wet conditions. This feature is especially important in industries where spillage is commonplace, such as in chemical processing or food and beverage manufacturing. In conclusion, galvanized walkway grating combines strength, durability, and environmental sustainability, making it a preferred choice for a wide range of applications. Its unparalleled resistance to corrosion and wear, coupled with its ease of maintenance and adherence to safety standards, positions it as a reliable and authoritative product in the domain of industrial flooring solutions. Whether employed in heavy industrial environments or used in commercial and residential situations, galvanized walkway grating consistently proves its worth, ensuring safety, durability, and peace of mind for companies and individuals alike.

Maintenance of galvanized walkway grating is relatively straightforward, thanks to its protective zinc coating, which diminishes the frequency of upkeep activities. The surface naturally resists dirt and grime build-up, requiring only periodic cleaning to maintain its optimal condition. This ease of maintenance not only reduces operational costs but also ensures that the grating retains its aesthetic appeal and functional integrity years after installation. Environmental considerations also play a crucial role in the selection of galvanized walkway grating. The galvanizing process itself is environmentally friendly, with zinc being fully recyclable and less energy-intensive than other protective coatings. This eco-conscious element of the grating aligns with sustainable practices, allowing companies to meet green building standards and certifications. In terms of safety, galvanized walkway grating offers exceptional slip resistance, which is crucial in preventing accidents and ensuring the safety of workers and pedestrians. The grating's serrated edges provide added grip, making it suitable for both dry and wet conditions. This feature is especially important in industries where spillage is commonplace, such as in chemical processing or food and beverage manufacturing. In conclusion, galvanized walkway grating combines strength, durability, and environmental sustainability, making it a preferred choice for a wide range of applications. Its unparalleled resistance to corrosion and wear, coupled with its ease of maintenance and adherence to safety standards, positions it as a reliable and authoritative product in the domain of industrial flooring solutions. Whether employed in heavy industrial environments or used in commercial and residential situations, galvanized walkway grating consistently proves its worth, ensuring safety, durability, and peace of mind for companies and individuals alike.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024