- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 11:30

Back to list

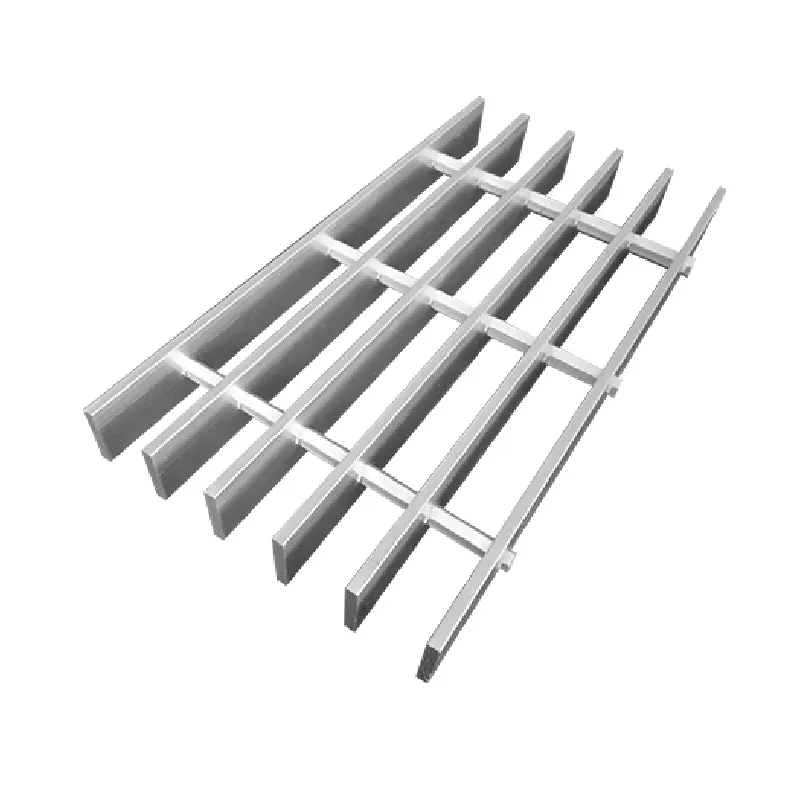

galvanized steel grating prices

Galvanized steel grating is a fundamental component in construction and industrial applications, known for its durability, safety features, and cost-efficiency. When it comes to making an informed purchasing decision, understanding the pricing nuances is essential for both small scale applications and large industrial projects.

One cannot overlook the galvanization process itself, which is a significant factor affecting cost. Galvanization ensures that the steel grating is corrosion-resistant, extending its lifespan. The process involves coating the steel in zinc, which, while adding to the initial cost, offers long-term savings by reducing maintenance and replacement needs. Depending on the zinc thickness and the method of galvanization (such as hot-dip galvanizing or electro-galvanizing), prices can fluctuate. Generally, hot-dip galvanizing, which involves immersing the grating in molten zinc, provides superior protection and is thus more expensive compared to electro-galvanizing. Market conditions and geopolitical factors also play a critical role in determining galvanized steel grating prices. Fluctuations in steel prices, largely due to global supply chain issues or tariffs, can lead to variable pricing. For example, a rapid increase in raw steel costs can directly lead to higher grating prices. It’s advisable to stay updated with global steel market trends and consider locking in prices when favorable conditions arise. Lastly, the supplier or manufacturer's reputation can influence pricing. Reputable manufacturers often provide premium quality gratings, following stringent quality controls and offering warranties, which can justify a higher price. Furthermore, bulk purchases can often lead to significant discounts, making it a strategic financial decision for larger projects. In summary, while galvanized steel grating prices are contingent upon a variety of factors including type, thickness, galvanization method, and market conditions, making an informed purchase requires a thorough understanding of the specific project requirements and current market dynamics. By evaluating these elements with expertise and precision, one can strategically select the right grating at a competitive price, ensuring safety, functionality, and durability in their application while optimizing cost-effectiveness.

One cannot overlook the galvanization process itself, which is a significant factor affecting cost. Galvanization ensures that the steel grating is corrosion-resistant, extending its lifespan. The process involves coating the steel in zinc, which, while adding to the initial cost, offers long-term savings by reducing maintenance and replacement needs. Depending on the zinc thickness and the method of galvanization (such as hot-dip galvanizing or electro-galvanizing), prices can fluctuate. Generally, hot-dip galvanizing, which involves immersing the grating in molten zinc, provides superior protection and is thus more expensive compared to electro-galvanizing. Market conditions and geopolitical factors also play a critical role in determining galvanized steel grating prices. Fluctuations in steel prices, largely due to global supply chain issues or tariffs, can lead to variable pricing. For example, a rapid increase in raw steel costs can directly lead to higher grating prices. It’s advisable to stay updated with global steel market trends and consider locking in prices when favorable conditions arise. Lastly, the supplier or manufacturer's reputation can influence pricing. Reputable manufacturers often provide premium quality gratings, following stringent quality controls and offering warranties, which can justify a higher price. Furthermore, bulk purchases can often lead to significant discounts, making it a strategic financial decision for larger projects. In summary, while galvanized steel grating prices are contingent upon a variety of factors including type, thickness, galvanization method, and market conditions, making an informed purchase requires a thorough understanding of the specific project requirements and current market dynamics. By evaluating these elements with expertise and precision, one can strategically select the right grating at a competitive price, ensuring safety, functionality, and durability in their application while optimizing cost-effectiveness.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024