- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 12:05

Back to list

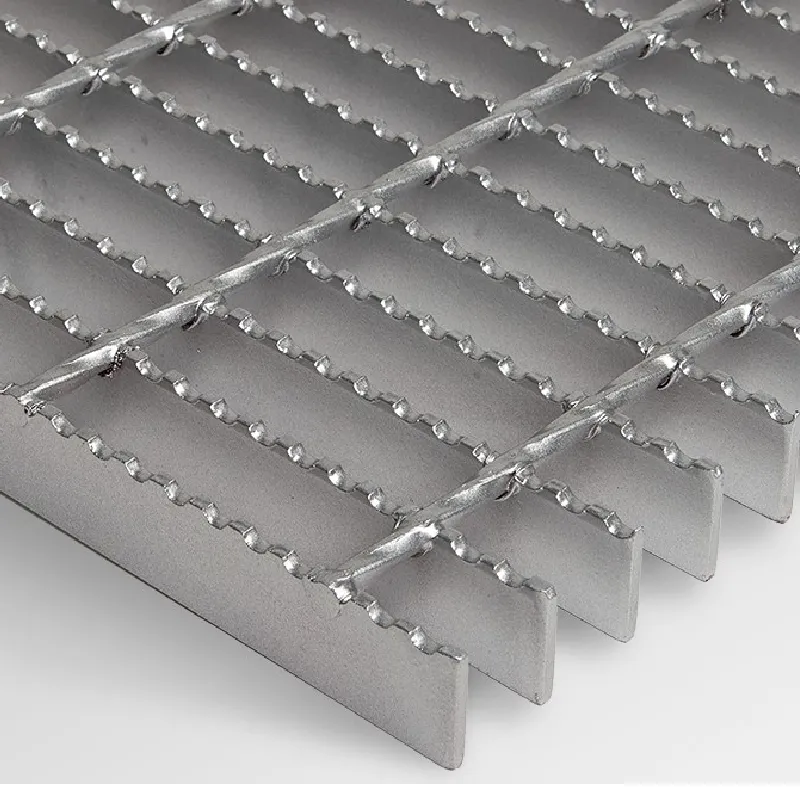

floor grating price

The importance of understanding floor grating prices is paramount for anyone involved in construction, architecture, or supply chain logistics of building materials. Floor grating, a fundamental American or European construction material, serves a multitude of purposes, combining functionality with aesthetic appeal. Having worked in this industry for over a decade, my expertise can help you navigate the varied aspects of floor grating prices and provide insight into making informed purchasing decisions.

Expertise in this domain highlights the role of market dynamics in pricing. Variations in raw material costs due to economic fluctuation, supply chain disruptions, and geopolitical events can substantially impact floor grating prices. Therefore, maintaining vendor relationships and understanding market conditions can provide price stabilization over long-term engagements. The seller's reputation and service quality also affect the final cost of floor grating. Vendors offering additional services such as customization, quality assurance, certification, and compliant delivery logistics might come with a premium. However, they ensure reliability and adherence to industry standards, which can be crucial for large-scale and safety-centric projects. Partnering with such vendors builds trust and often results in fewer supply-chain headaches. In-depth industry insight suggests that regional factors should not be overlooked. Locally sourced floor grating can sometimes be more economical due to reduced shipping costs. However, ensure these local suppliers meet the required quality standards. International purchases might provide a cost benefit but can come with added complexity in shipping logistics, import duties, and extended delivery times, which should be factored into total expenditure calculations. Finally, volume purchases can substantially influence floor grating pricing. Bulk buying not only potentially reduces the cost per unit due to economies of scale but also strengthens your negotiating position with suppliers. Seasoned procurement specialists often utilize fixed-price contracts to hedge against volatility in pricing. Building these strategies into your procurement plan will maximize financial efficiency. In conclusion, the multifaceted nature of floor grating prices necessitates a comprehensive evaluation of materials, dimensions, production methods, market conditions, supplier reliability, and purchase strategies. Leveraging the right combination ensures both economic efficiency and functional superiority in your construction endeavors. Your investment in understanding these dynamics will pay dividends in project outcomes, budget adherence, and ultimately, the safety and satisfaction of end-users.

Expertise in this domain highlights the role of market dynamics in pricing. Variations in raw material costs due to economic fluctuation, supply chain disruptions, and geopolitical events can substantially impact floor grating prices. Therefore, maintaining vendor relationships and understanding market conditions can provide price stabilization over long-term engagements. The seller's reputation and service quality also affect the final cost of floor grating. Vendors offering additional services such as customization, quality assurance, certification, and compliant delivery logistics might come with a premium. However, they ensure reliability and adherence to industry standards, which can be crucial for large-scale and safety-centric projects. Partnering with such vendors builds trust and often results in fewer supply-chain headaches. In-depth industry insight suggests that regional factors should not be overlooked. Locally sourced floor grating can sometimes be more economical due to reduced shipping costs. However, ensure these local suppliers meet the required quality standards. International purchases might provide a cost benefit but can come with added complexity in shipping logistics, import duties, and extended delivery times, which should be factored into total expenditure calculations. Finally, volume purchases can substantially influence floor grating pricing. Bulk buying not only potentially reduces the cost per unit due to economies of scale but also strengthens your negotiating position with suppliers. Seasoned procurement specialists often utilize fixed-price contracts to hedge against volatility in pricing. Building these strategies into your procurement plan will maximize financial efficiency. In conclusion, the multifaceted nature of floor grating prices necessitates a comprehensive evaluation of materials, dimensions, production methods, market conditions, supplier reliability, and purchase strategies. Leveraging the right combination ensures both economic efficiency and functional superiority in your construction endeavors. Your investment in understanding these dynamics will pay dividends in project outcomes, budget adherence, and ultimately, the safety and satisfaction of end-users.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024