- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 30, 2025 04:06

Back to list

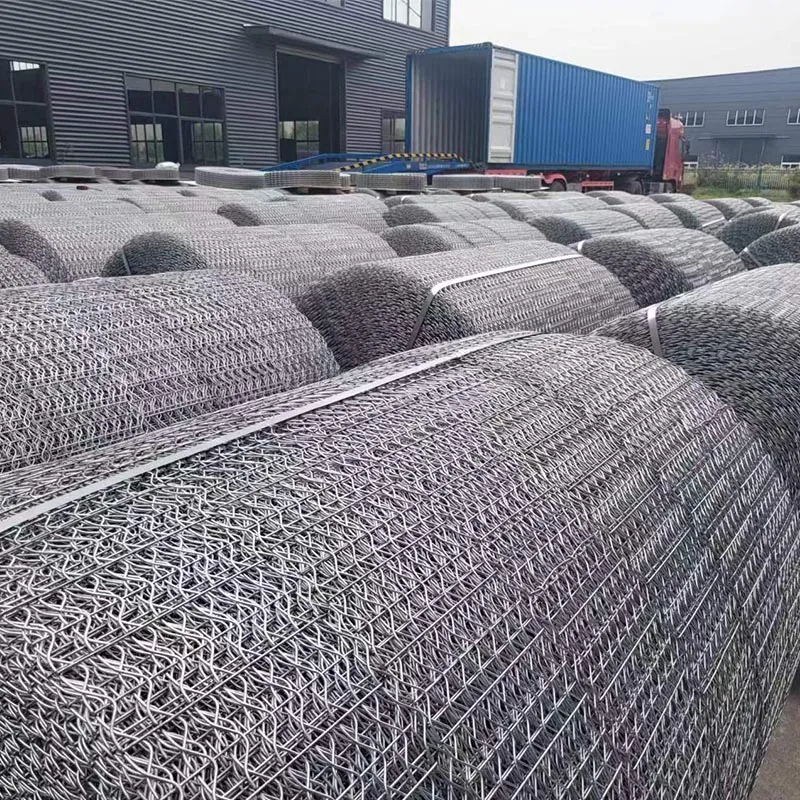

serrated steel grating

Galvanized serrated bar grating is quickly becoming a crucial component in various industrial applications due to its durability and slip-resistant properties. As industries transition to more efficient and safer operations, understanding the inherent advantages of this product is vital for selecting the appropriate materials for infrastructure projects. This article delves into the real-world applications, expert insights, authoritative recommendations, and trustworthy evaluations surrounding galvanized serrated bar grating, offering an in-depth analysis for professionals considering its use.

Trustworthiness is further emphasized by the robust performance reviews and feedback from long-term research studies examining the lifecycle and environmental impact of galvanized serrated bar grating. Independent audits and test results consistently underscore its high tensile strength and weather resistance, while sustainability reports demonstrate that the galvanization process adheres to environmentally friendly practices. This assurance is augmented by the warranty services offered by leading manufacturers, who not only stand by the material's performance but also provide extensive support and service options, facilitating greater confidence among users. In aggregate, galvanized serrated bar grating emerges as a tried-and-tested solution for industries aiming to amalgamate durability, safety, and compliance into their operational frameworks. Its adoption is a testament to a preference for materials that do not only meet immediate functional needs but also integrate seamlessly into long-term strategic objectives prioritized by businesses. For industries keen on upgrading their infrastructural elements, galvanized serrated bar grating offers a confluence of reliability, professional endorsement, and industry acknowledgment. The consideration of real-world experiences alongside professional expertise makes a compelling case for its inclusion in safety and infrastructure enhancements. Thus, businesses and decision-makers seeking reliable, sustainable, and efficient materials find in galvanized serrated bar grating an ideal solution that meets both current and future industrial demands.

Trustworthiness is further emphasized by the robust performance reviews and feedback from long-term research studies examining the lifecycle and environmental impact of galvanized serrated bar grating. Independent audits and test results consistently underscore its high tensile strength and weather resistance, while sustainability reports demonstrate that the galvanization process adheres to environmentally friendly practices. This assurance is augmented by the warranty services offered by leading manufacturers, who not only stand by the material's performance but also provide extensive support and service options, facilitating greater confidence among users. In aggregate, galvanized serrated bar grating emerges as a tried-and-tested solution for industries aiming to amalgamate durability, safety, and compliance into their operational frameworks. Its adoption is a testament to a preference for materials that do not only meet immediate functional needs but also integrate seamlessly into long-term strategic objectives prioritized by businesses. For industries keen on upgrading their infrastructural elements, galvanized serrated bar grating offers a confluence of reliability, professional endorsement, and industry acknowledgment. The consideration of real-world experiences alongside professional expertise makes a compelling case for its inclusion in safety and infrastructure enhancements. Thus, businesses and decision-makers seeking reliable, sustainable, and efficient materials find in galvanized serrated bar grating an ideal solution that meets both current and future industrial demands.

Share

Prev:

Next:

Latest news

-

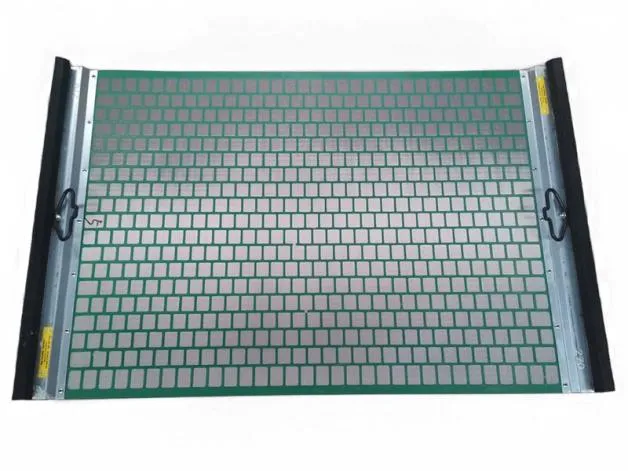

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024