- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 23, 2025 05:00

Back to list

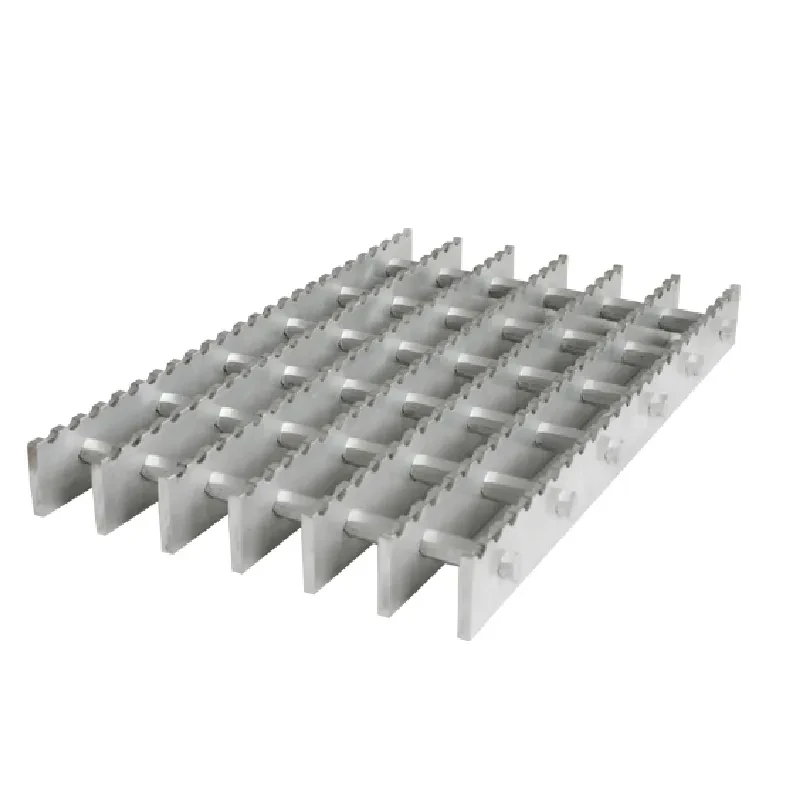

Swage-Locked Steel Grating

Galvanized metal grating has emerged as a preferred choice in various industries, thanks to its robustness, versatility, and longevity. This remarkable material is not just a mere construction component but a game-changer in the world of industrial applications, reflecting years of expertise and innovation.

Real-world experiences consistently highlight the practical benefits of galvanized metal grating. Facility managers and infrastructure supervisors praise its minimal maintenance requirements and cost-effectiveness. Unlike other materials that may demand frequent repairs or replacements, galvanized grating remains structurally sound over time, providing a long-term solution and significant return on investment. It's common to find testimonials that emphasize the material's ease of installation and customization, further cementing its reputation in real-world applications. Ensuring safety is another vital aspect where galvanized metal grating exhibits excellence. Its non-slip surface reduces the risk of workplace accidents, which is a significant concern in industrial settings. Engineers often recommend it in areas prone to liquid spillage or where substances may accumulate on the surface. This safety feature not only protects employees but also reflects the responsibility and trustworthiness of a company in maintaining secure working conditions. As sustainability becomes an increasingly important consideration for businesses, galvanized metal grating aligns well with eco-friendly practices. The use of recyclable materials and the long lifespan minimizes the environmental impact, demonstrating an ethical approach while maintaining functionality and dependability. In conclusion, galvanized metal grating exemplifies the interplay of professional expertise, strategic innovation, and durable reliability. It is more than just a product; it is a solution masterfully crafted to meet the evolving demands of modern industry. Those who opt for galvanized metal grating benefit from a tried-and-tested resource that withstands the test of time, attesting to its unmatched quality and industry authority.

Real-world experiences consistently highlight the practical benefits of galvanized metal grating. Facility managers and infrastructure supervisors praise its minimal maintenance requirements and cost-effectiveness. Unlike other materials that may demand frequent repairs or replacements, galvanized grating remains structurally sound over time, providing a long-term solution and significant return on investment. It's common to find testimonials that emphasize the material's ease of installation and customization, further cementing its reputation in real-world applications. Ensuring safety is another vital aspect where galvanized metal grating exhibits excellence. Its non-slip surface reduces the risk of workplace accidents, which is a significant concern in industrial settings. Engineers often recommend it in areas prone to liquid spillage or where substances may accumulate on the surface. This safety feature not only protects employees but also reflects the responsibility and trustworthiness of a company in maintaining secure working conditions. As sustainability becomes an increasingly important consideration for businesses, galvanized metal grating aligns well with eco-friendly practices. The use of recyclable materials and the long lifespan minimizes the environmental impact, demonstrating an ethical approach while maintaining functionality and dependability. In conclusion, galvanized metal grating exemplifies the interplay of professional expertise, strategic innovation, and durable reliability. It is more than just a product; it is a solution masterfully crafted to meet the evolving demands of modern industry. Those who opt for galvanized metal grating benefit from a tried-and-tested resource that withstands the test of time, attesting to its unmatched quality and industry authority.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024