- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 28, 2025 02:52

Back to list

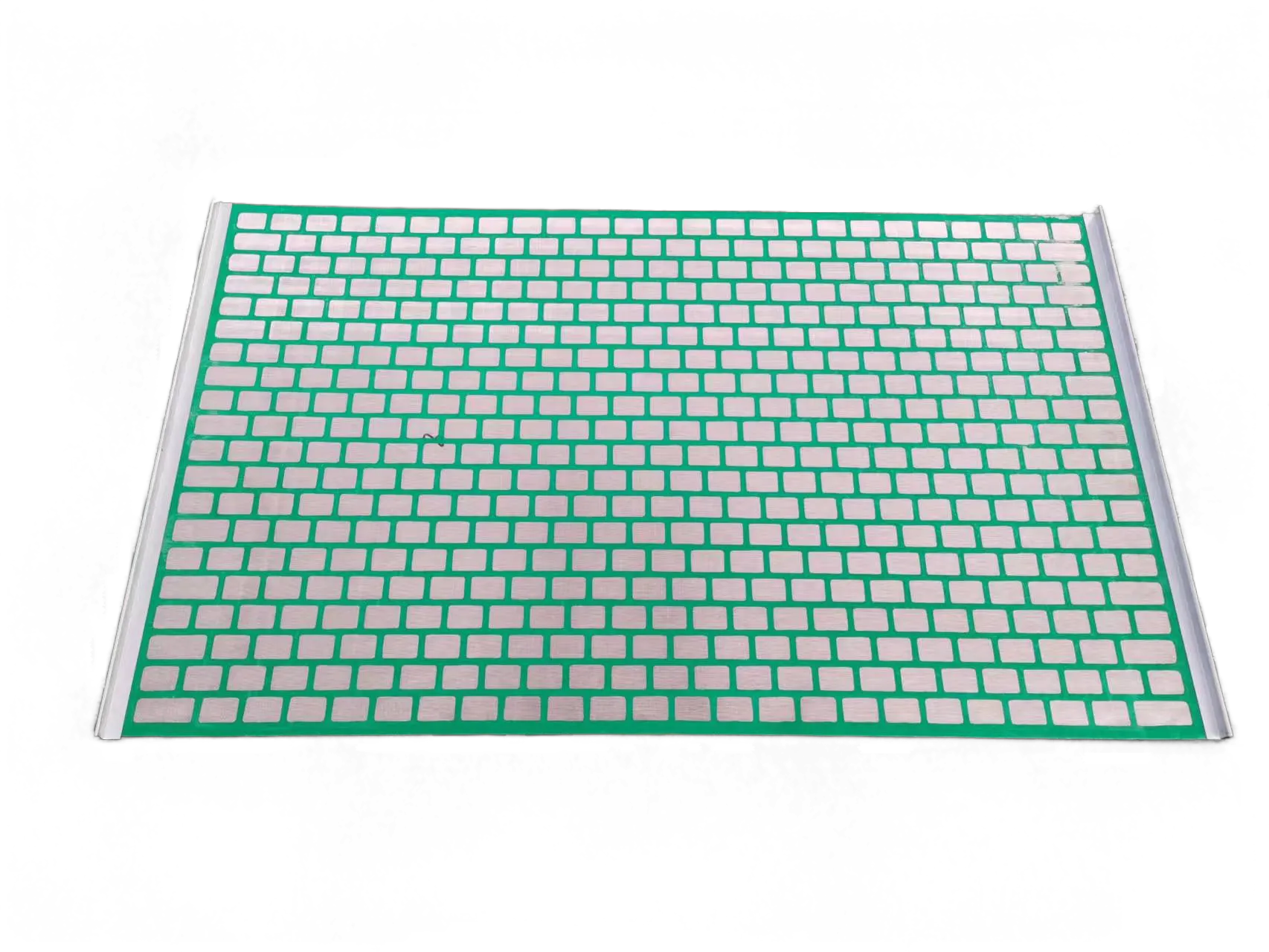

heavy-duty welded bar grating

Galvanized steel bar grating has emerged as a vital component in industrial, commercial, and even residential applications due to its durability, strength, and cost-effectiveness. Understanding the cost dynamics of galvanized bar grating can equip buyers and industry stakeholders with the necessary insights to make informed purchasing decisions.

Authoritativeness in Market Influences on Cost Industry authorities frequently address how several external factors can impact the pricing of galvanized bar grating. For example, tariff implementations and international trade policies can lead to significant price hikes or reductions. Authoritative bodies in metal and construction industries often provide market forecasts and reports that predict such trends, offering invaluable guidance for budget planning. The supply chain dynamics also come into play, particularly with respect to lead times and stock availability. As authorities point out, certain regions or suppliers might experience delays or shortages, driving up prices temporarily. Therefore, sourcing from a reliable supplier with established supply chains can mitigate unforeseen expenses. Trustworthiness in Supplier Selection and Cost Optimization Building trust with suppliers is pivotal in navigating the costs associated with galvanized bar grating. Trusted suppliers not only offer competitive pricing but also transparency in terms of additional fees, such as shipping and handling. Industry veterans suggest engaging with suppliers who provide detailed quotes and have a track record of reliability. Furthermore, establishing a collaborative relationship with suppliers can yield additional benefits such as discounts for bulk orders or repeat business. Trustworthy suppliers can also offer insights into cost-saving opportunities, such as utilizing off-cuts or alternative grating types that meet project specifications without compromising integrity. In conclusion, galvanized bar grating presents a balance of cost against a backdrop of performance and reliability. By leveraging experience, relying on professional expertise, consulting authoritative sources, and fostering trustworthy supplier relationships, stakeholders can optimize their investment and achieve long-term benefits. The key lies in understanding the nuanced elements that drive costs and proactively managing them to align with project goals and budgetary constraints.

Authoritativeness in Market Influences on Cost Industry authorities frequently address how several external factors can impact the pricing of galvanized bar grating. For example, tariff implementations and international trade policies can lead to significant price hikes or reductions. Authoritative bodies in metal and construction industries often provide market forecasts and reports that predict such trends, offering invaluable guidance for budget planning. The supply chain dynamics also come into play, particularly with respect to lead times and stock availability. As authorities point out, certain regions or suppliers might experience delays or shortages, driving up prices temporarily. Therefore, sourcing from a reliable supplier with established supply chains can mitigate unforeseen expenses. Trustworthiness in Supplier Selection and Cost Optimization Building trust with suppliers is pivotal in navigating the costs associated with galvanized bar grating. Trusted suppliers not only offer competitive pricing but also transparency in terms of additional fees, such as shipping and handling. Industry veterans suggest engaging with suppliers who provide detailed quotes and have a track record of reliability. Furthermore, establishing a collaborative relationship with suppliers can yield additional benefits such as discounts for bulk orders or repeat business. Trustworthy suppliers can also offer insights into cost-saving opportunities, such as utilizing off-cuts or alternative grating types that meet project specifications without compromising integrity. In conclusion, galvanized bar grating presents a balance of cost against a backdrop of performance and reliability. By leveraging experience, relying on professional expertise, consulting authoritative sources, and fostering trustworthy supplier relationships, stakeholders can optimize their investment and achieve long-term benefits. The key lies in understanding the nuanced elements that drive costs and proactively managing them to align with project goals and budgetary constraints.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024