- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 21, 2025 02:14

Back to list

stainless steel rope helipad perimeter safety netting

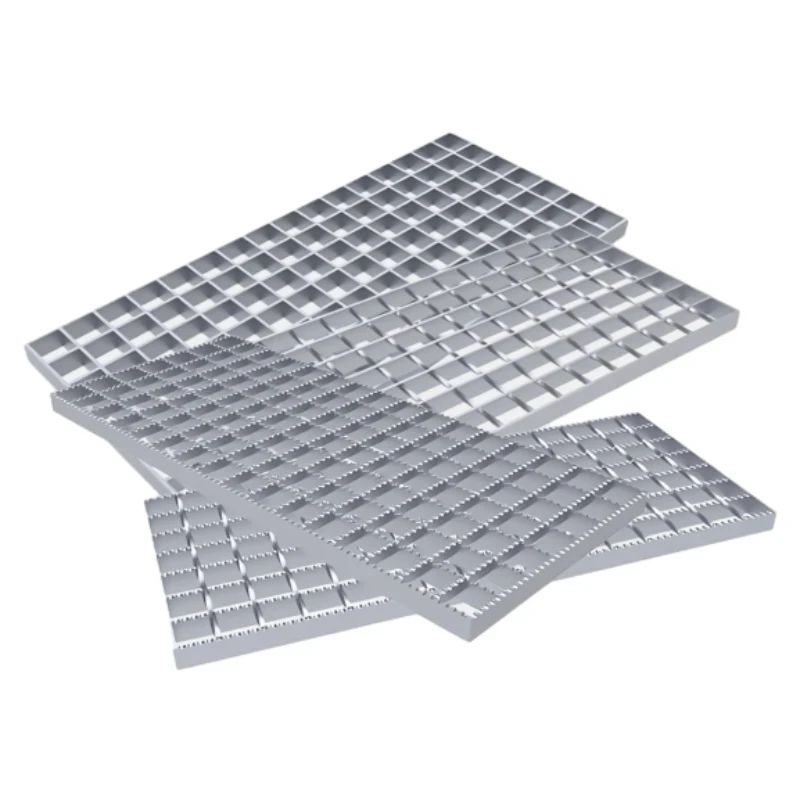

Galvanized steel grids play a pivotal role in numerous industrial and commercial applications, highlighting not only their manifold uses but also their superiority as a material choice. The intricate process of galvanization, which involves coating the steel with a protective layer of zinc, imbues it with exceptional resistance to corrosion, thereby bolstering its lifespan dramatically. In environments where exposure to moisture and chemicals is frequent, galvanized steel grids emerge as an unrivaled candidate due to their robustness and durability.

The environmental aspect of galvanized steel grids also lends them an advantage in the modern sustainable building ethos. The longevity of these materials, coupled with the fact that steel is one of the most recycled materials globally, positions galvanized steel grids as an eco-conscious choice. Their recyclability ensures that their life cycle supports reduced environmental impact, which is a compelling factor for businesses and industries striving for sustainability credentials. A critical aspect of experience and professionalism lies in installation and maintenance requirements for galvanized steel grids. While installation can often appear straightforward, ensuring the longevity and optimal performance of these grids demands experienced oversight. Proper handling during the installation process can mitigate risks such as warping or structural compromise while regular maintenance checks—although minimal due to the nature of the material—ensure early detection of potential issues, thus preserving the structural integrity. The trust in galvanized steel grids can also be quantified by innovations seen in enhanced coatings and manufacturing techniques, pushing the boundaries of their effectiveness even further. Modern advancements have resulted in coatings that provide even higher resistance not only to corrosion but also to abrasion and impact, thereby expanding their suitability to environments where traditional galvanized solutions would fare less favorably. In conclusion, galvanized steel grids are more than mere materials; they embody a synthesis of technology and art, offering solutions that are as reliable as they are versatile. For entities ranging from small businesses to large-scale industrial operations, the utility and advantages of these grids align closely with safety, efficiency, and sustainability objectives. This makes galvanized steel grids an authoritative choice in the realm of construction materials, fostering trust with stakeholders who prioritize quality and longevity in both products and processes.

The environmental aspect of galvanized steel grids also lends them an advantage in the modern sustainable building ethos. The longevity of these materials, coupled with the fact that steel is one of the most recycled materials globally, positions galvanized steel grids as an eco-conscious choice. Their recyclability ensures that their life cycle supports reduced environmental impact, which is a compelling factor for businesses and industries striving for sustainability credentials. A critical aspect of experience and professionalism lies in installation and maintenance requirements for galvanized steel grids. While installation can often appear straightforward, ensuring the longevity and optimal performance of these grids demands experienced oversight. Proper handling during the installation process can mitigate risks such as warping or structural compromise while regular maintenance checks—although minimal due to the nature of the material—ensure early detection of potential issues, thus preserving the structural integrity. The trust in galvanized steel grids can also be quantified by innovations seen in enhanced coatings and manufacturing techniques, pushing the boundaries of their effectiveness even further. Modern advancements have resulted in coatings that provide even higher resistance not only to corrosion but also to abrasion and impact, thereby expanding their suitability to environments where traditional galvanized solutions would fare less favorably. In conclusion, galvanized steel grids are more than mere materials; they embody a synthesis of technology and art, offering solutions that are as reliable as they are versatile. For entities ranging from small businesses to large-scale industrial operations, the utility and advantages of these grids align closely with safety, efficiency, and sustainability objectives. This makes galvanized steel grids an authoritative choice in the realm of construction materials, fostering trust with stakeholders who prioritize quality and longevity in both products and processes.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024