- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 21, 2025 03:00

Back to list

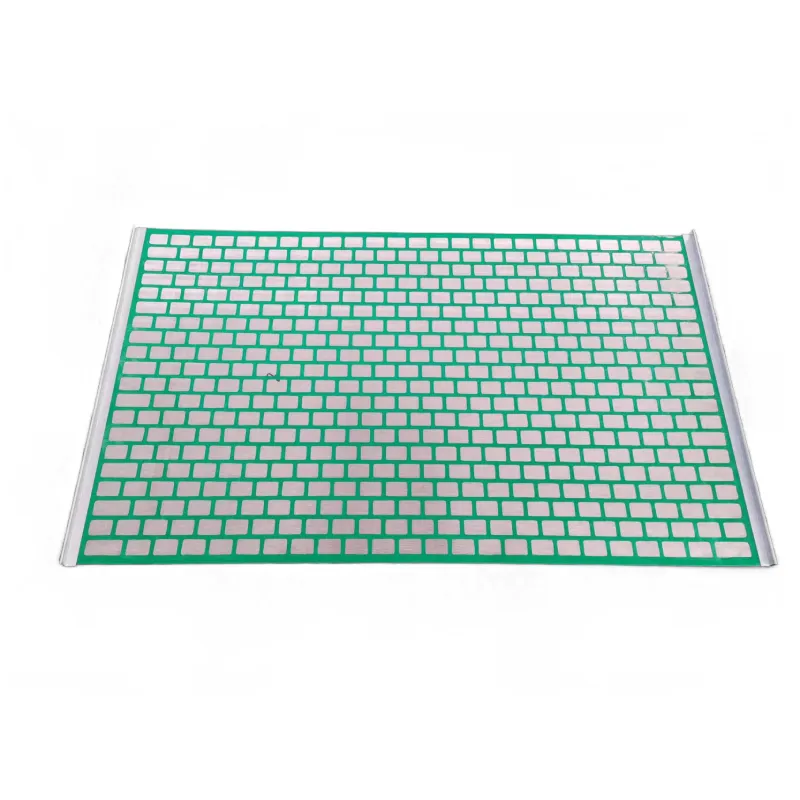

metal grating for sale

Galvanised metal grating has become a cornerstone of modern industrial and commercial applications, providing a robust solution for flooring, walkway, and safety barriers. The process of galvanisation, which involves coating the metal, typically steel, with a protective layer of zinc, significantly enhances the durability and corrosion resistance of the grating. Here, we delve into why galvanised metal grating is revered in various sectors, exploring real-world experiences, professional insights, and the authoritative reasons that drive its adoption.

Innovation has not bypassed galvanised metal grating, either. Recent advances have seen the integration of additional features that cater to specific industrial needs. For instance, electrically conductive gratings are gaining popularity in electronics manufacturing, where static discharge poses a risk. Here, galvanised grating not only solves structural needs but also mitigates electrical hazards, showcasing adaptability and advanced problem-solving. Cost-effectiveness is another compelling argument that experts present for the wide-scale adoption of galvanised metal grating. While the initial investment in galvanised products might be marginally higher than in non-galvanised alternatives, the lifecycle cost benefits are substantial. Reduced maintenance needs and extended longevity mean that over time, facilities incur lower costs, making galvanised grating a financially prudent choice. Moreover, galvanised metal grating aligns with modern sustainability goals. Zinc itself is a natural, abundant resource, and galvanisation extends the material's life, delaying the need for replacement and reducing waste. Furthermore, at the end of its use phase, both steel and zinc are recyclable, reinforcing the eco-friendly credentials of galvanised metal grating and its alignment with the circular economy. The credibility of those who champion galvanised metal grating is also central to its reputation. Industry leaders, from architects to safety officers, advocate for its use, often backed by robust case studies that highlight successful implementations across various sectors. This collective endorsement from professionals who rely on its performance builds a narrative of trustworthiness that is pivotal in construction and industrial circles. In conclusion, galvanised metal grating is not merely a product but a solution borne out of extensive research and development, practical application, and industry endorsement. Its unparalleled durability, combined with a plethora of functional features and environmental benefits, make it an indispensable component in modern infrastructure projects. Embracing this technology is not just a nod to enhanced performance but a stride towards safer, more economical, and environmentally responsible industrial practices.

Innovation has not bypassed galvanised metal grating, either. Recent advances have seen the integration of additional features that cater to specific industrial needs. For instance, electrically conductive gratings are gaining popularity in electronics manufacturing, where static discharge poses a risk. Here, galvanised grating not only solves structural needs but also mitigates electrical hazards, showcasing adaptability and advanced problem-solving. Cost-effectiveness is another compelling argument that experts present for the wide-scale adoption of galvanised metal grating. While the initial investment in galvanised products might be marginally higher than in non-galvanised alternatives, the lifecycle cost benefits are substantial. Reduced maintenance needs and extended longevity mean that over time, facilities incur lower costs, making galvanised grating a financially prudent choice. Moreover, galvanised metal grating aligns with modern sustainability goals. Zinc itself is a natural, abundant resource, and galvanisation extends the material's life, delaying the need for replacement and reducing waste. Furthermore, at the end of its use phase, both steel and zinc are recyclable, reinforcing the eco-friendly credentials of galvanised metal grating and its alignment with the circular economy. The credibility of those who champion galvanised metal grating is also central to its reputation. Industry leaders, from architects to safety officers, advocate for its use, often backed by robust case studies that highlight successful implementations across various sectors. This collective endorsement from professionals who rely on its performance builds a narrative of trustworthiness that is pivotal in construction and industrial circles. In conclusion, galvanised metal grating is not merely a product but a solution borne out of extensive research and development, practical application, and industry endorsement. Its unparalleled durability, combined with a plethora of functional features and environmental benefits, make it an indispensable component in modern infrastructure projects. Embracing this technology is not just a nod to enhanced performance but a stride towards safer, more economical, and environmentally responsible industrial practices.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024