- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 17:18

Back to list

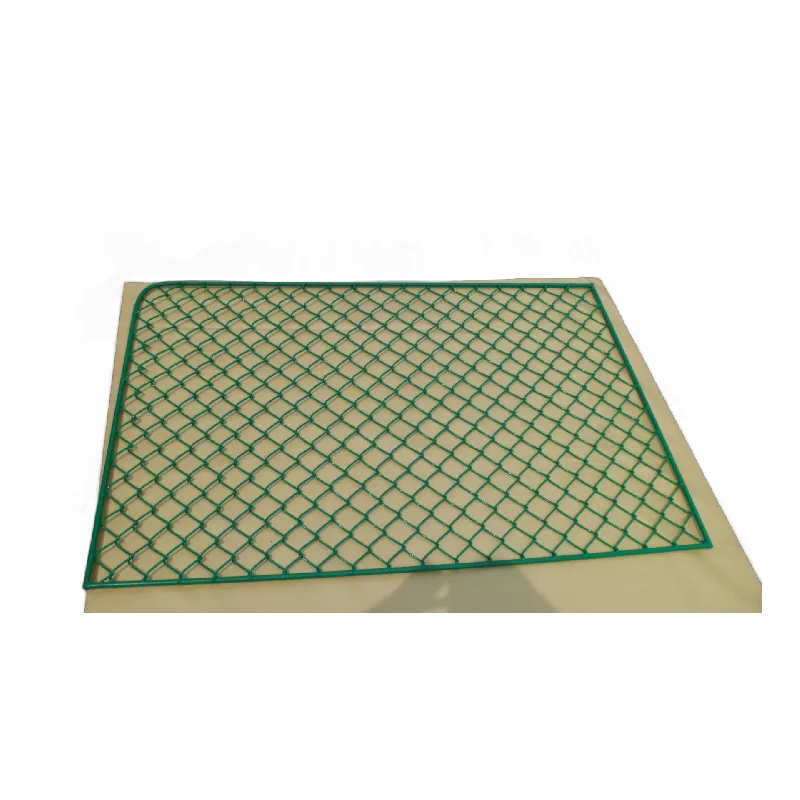

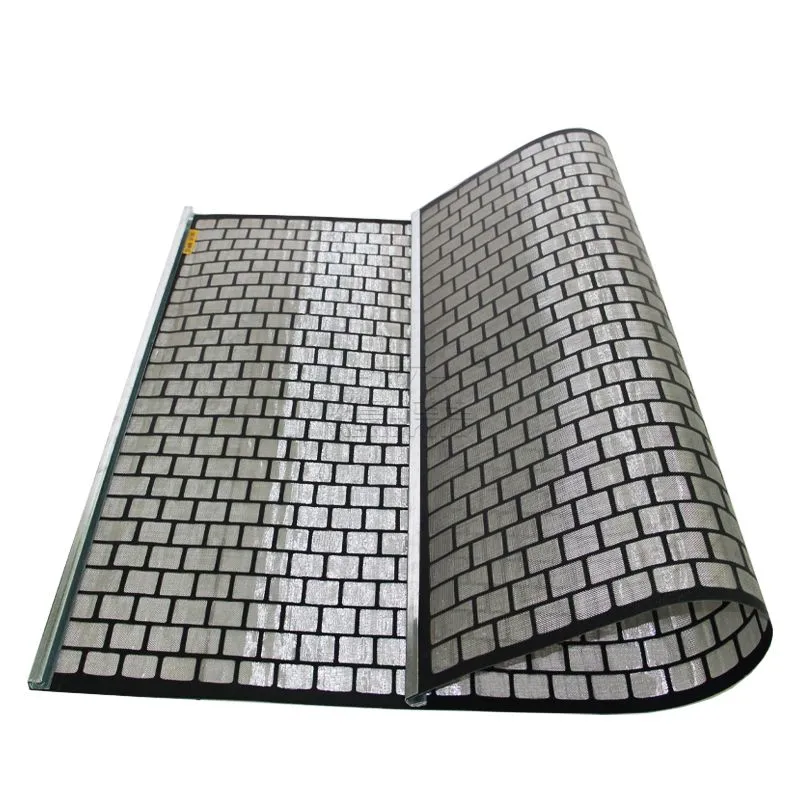

metal walkways gratings

Galvanized metal grates are an essential component in various industries due to their exceptional durability, versatility, and corrosion-resistant properties. These grates find applications ranging from residential drainage systems to heavy-duty industrial platforms, where safety and efficiency are paramount. With a growing focus on longevity and maintenance-free solutions in infrastructure and construction, galvanized metal grates have emerged as an ideal choice. This article explores the intrinsic qualities of galvanized metal grates while providing expert insights into their practical applications and benefits, underpinned by trust and authority.

The use of galvanized metal grates in industries extends to manufacturing environments, where their slip-resistant surfaces are crucial for workplace safety. In settings such as factories or warehouses, these grates offer protection against slips and falls, making them critical in facilities where spills or wet conditions are frequent. Additionally, for industries dealing with volatile chemicals or high humidity levels, the non-reactive zinc coating adds a layer of protection, safeguarding both the infrastructure and the workforce. Trust in galvanized metal grates is further reinforced by industry standards and compliance benchmarks. Organizations like the American Galvanizers Association (AGA) provide guidelines and best practices for the production and usage of galvanized materials, ensuring that products meet and exceed safety and quality standards. This assurance of credibility is critical for decision-makers in procurement and project management, as it offers peace of mind that the materials used will perform reliably under rigorous conditions. In conclusion, galvanized metal grates represent a perfect blend of resilience, efficiency, and cost-effectiveness. Their adoption across various domains underscores their adaptability and endurance in challenging environments. By investing in galvanized solutions, industries solidify their commitment to quality infrastructure, aligning with modern demands for durability and sustainability. As the only solution that combines these attributes with minimal upkeep, galvanized metal grates undoubtedly stand out as a peak choice for today’s infrastructure and industrial needs.

The use of galvanized metal grates in industries extends to manufacturing environments, where their slip-resistant surfaces are crucial for workplace safety. In settings such as factories or warehouses, these grates offer protection against slips and falls, making them critical in facilities where spills or wet conditions are frequent. Additionally, for industries dealing with volatile chemicals or high humidity levels, the non-reactive zinc coating adds a layer of protection, safeguarding both the infrastructure and the workforce. Trust in galvanized metal grates is further reinforced by industry standards and compliance benchmarks. Organizations like the American Galvanizers Association (AGA) provide guidelines and best practices for the production and usage of galvanized materials, ensuring that products meet and exceed safety and quality standards. This assurance of credibility is critical for decision-makers in procurement and project management, as it offers peace of mind that the materials used will perform reliably under rigorous conditions. In conclusion, galvanized metal grates represent a perfect blend of resilience, efficiency, and cost-effectiveness. Their adoption across various domains underscores their adaptability and endurance in challenging environments. By investing in galvanized solutions, industries solidify their commitment to quality infrastructure, aligning with modern demands for durability and sustainability. As the only solution that combines these attributes with minimal upkeep, galvanized metal grates undoubtedly stand out as a peak choice for today’s infrastructure and industrial needs.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024