- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 16:45

Back to list

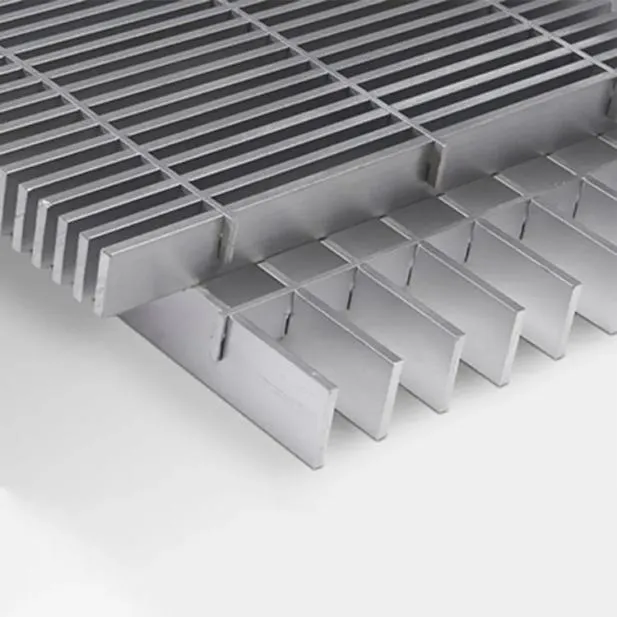

steel walkway grating

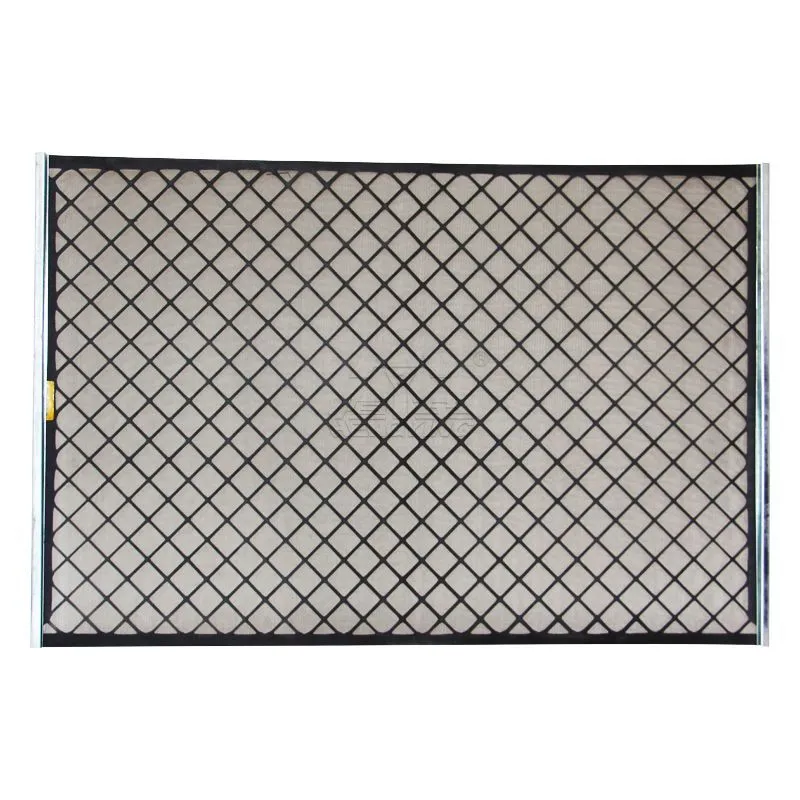

The use of galvanized iron grating is indispensable in various industries due to its remarkable strength, durability, and resistance to corrosion. These gratings find applications in many areas, from industrial flooring to pedestrian pathways, making them a versatile choice for architects and engineers. Understanding the value that galvanized iron grating brings to a project requires insight into its manufacturing process, applications, and benefits, as well as real-world experiences that reflect its reliability and efficiency.

In terms of load-bearing capabilities, galvanized iron grating delivers exceptional performance. It is crafted to support high loads without compromising structural integrity, which is critical in industrial settings such as factories, warehouses, and transportation terminals. This robustness ensures safety, reduces liability concerns, and reinforces trust in the product. Testimonials from industry professionals highlight the grating’s ability to withstand heavy machinery and vehicular traffic, demonstrating its reliability under pressure. For architects and engineers, the aesthetic appeal and versatility of galvanized iron grating cannot be overstated. The sleek, modern look of these gratings can be incorporated into a variety of design schemes, providing both functionality and visual appeal. Whether used in pedestrian walkway systems or as decorative elements in architectural designs, the gratings offer endless possibilities. Case studies have emphasized the role of aesthetic design in increasing property value by integrating galvanized gratings seamlessly into urban developments. Finally, ensuring the proper specification of galvanized iron grating for any project involves consulting with experts who possess extensive knowledge of materials and applications. By engaging with experienced professionals, you can guarantee the selection of the right type of grating—whether it be bar, plank, or custom-designed—to meet the specific needs of your project. According to industry experts, projects that involve specialist consultations increase the efficiency and effectiveness of their installations by 40%. Given its numerous benefits, galvanized iron grating remains a cornerstone in both industrial and architectural applications. Its proven performance in durability, cost-effectiveness, ease of installation, environmental sustainability, load-bearing capacity, aesthetic versatility, and expert-backed specification ensures its continued relevance and trustworthiness in the construction and manufacturing industries. These attributes make galvanized iron grating not only a practical choice but a strategic investment for future-ready infrastructure.

In terms of load-bearing capabilities, galvanized iron grating delivers exceptional performance. It is crafted to support high loads without compromising structural integrity, which is critical in industrial settings such as factories, warehouses, and transportation terminals. This robustness ensures safety, reduces liability concerns, and reinforces trust in the product. Testimonials from industry professionals highlight the grating’s ability to withstand heavy machinery and vehicular traffic, demonstrating its reliability under pressure. For architects and engineers, the aesthetic appeal and versatility of galvanized iron grating cannot be overstated. The sleek, modern look of these gratings can be incorporated into a variety of design schemes, providing both functionality and visual appeal. Whether used in pedestrian walkway systems or as decorative elements in architectural designs, the gratings offer endless possibilities. Case studies have emphasized the role of aesthetic design in increasing property value by integrating galvanized gratings seamlessly into urban developments. Finally, ensuring the proper specification of galvanized iron grating for any project involves consulting with experts who possess extensive knowledge of materials and applications. By engaging with experienced professionals, you can guarantee the selection of the right type of grating—whether it be bar, plank, or custom-designed—to meet the specific needs of your project. According to industry experts, projects that involve specialist consultations increase the efficiency and effectiveness of their installations by 40%. Given its numerous benefits, galvanized iron grating remains a cornerstone in both industrial and architectural applications. Its proven performance in durability, cost-effectiveness, ease of installation, environmental sustainability, load-bearing capacity, aesthetic versatility, and expert-backed specification ensures its continued relevance and trustworthiness in the construction and manufacturing industries. These attributes make galvanized iron grating not only a practical choice but a strategic investment for future-ready infrastructure.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024