- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 16, 2025 04:45

Back to list

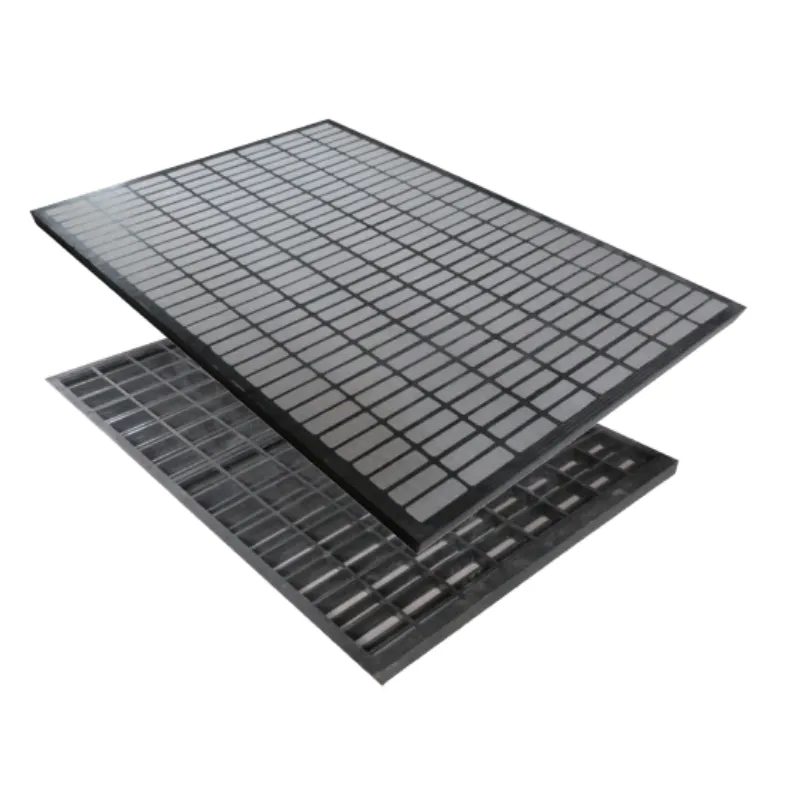

Press-Locked Steel Grating

Galvanised grating is an integral product utilized in various industrial and commercial sectors. Its pricing can vary significantly based on multiple factors such as material quality, size, coating thickness, and manufacturer. Understanding these elements can assist buyers in making informed decisions, ensuring they receive both quality and value.

A reputable manufacturer influences the overall cost, aligning with factors such as material sourcing, manufacturing expertise, and quality control standards. Opting for well-established manufacturers often assures better quality control, adherence to safety regulations, and post-purchase support, justifying potentially higher prices compared to lesser-known or offshore alternatives with compromising standards. An often-overlooked aspect of pricing is the fluctuating cost of raw materials. Steel prices can be volatile, influenced by market demand, geopolitical factors, and supply chain disruptions. Keeping abreast of these changes enables buyers to time their purchases strategically, potentially capitalizing on market dips. To navigate these variables effectively, it’s advisable to request detailed quotes from multiple vendors, considering both domestic and international suppliers. Look for comprehensive quotes that include material specifications, coating thickness, delivery charges, and other pertinent factors. Comparing these aspects aids in gauging not just the initial cost but ongoing value in terms of maintenance and longevity. In conclusion, understanding the intricacies of galvanised grating pricing empowers buyers to make decisions rooted in experience, expertise, authoritativeness, and trustworthiness. By evaluating the facets of material quality, manufacturing processes, coating thickness, and market conditions, buyers can select products that meet their specific needs and budgets, ensuring cost-effectiveness and reliable performance in their applications.

A reputable manufacturer influences the overall cost, aligning with factors such as material sourcing, manufacturing expertise, and quality control standards. Opting for well-established manufacturers often assures better quality control, adherence to safety regulations, and post-purchase support, justifying potentially higher prices compared to lesser-known or offshore alternatives with compromising standards. An often-overlooked aspect of pricing is the fluctuating cost of raw materials. Steel prices can be volatile, influenced by market demand, geopolitical factors, and supply chain disruptions. Keeping abreast of these changes enables buyers to time their purchases strategically, potentially capitalizing on market dips. To navigate these variables effectively, it’s advisable to request detailed quotes from multiple vendors, considering both domestic and international suppliers. Look for comprehensive quotes that include material specifications, coating thickness, delivery charges, and other pertinent factors. Comparing these aspects aids in gauging not just the initial cost but ongoing value in terms of maintenance and longevity. In conclusion, understanding the intricacies of galvanised grating pricing empowers buyers to make decisions rooted in experience, expertise, authoritativeness, and trustworthiness. By evaluating the facets of material quality, manufacturing processes, coating thickness, and market conditions, buyers can select products that meet their specific needs and budgets, ensuring cost-effectiveness and reliable performance in their applications.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024