- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 29, 2025 02:19

Back to list

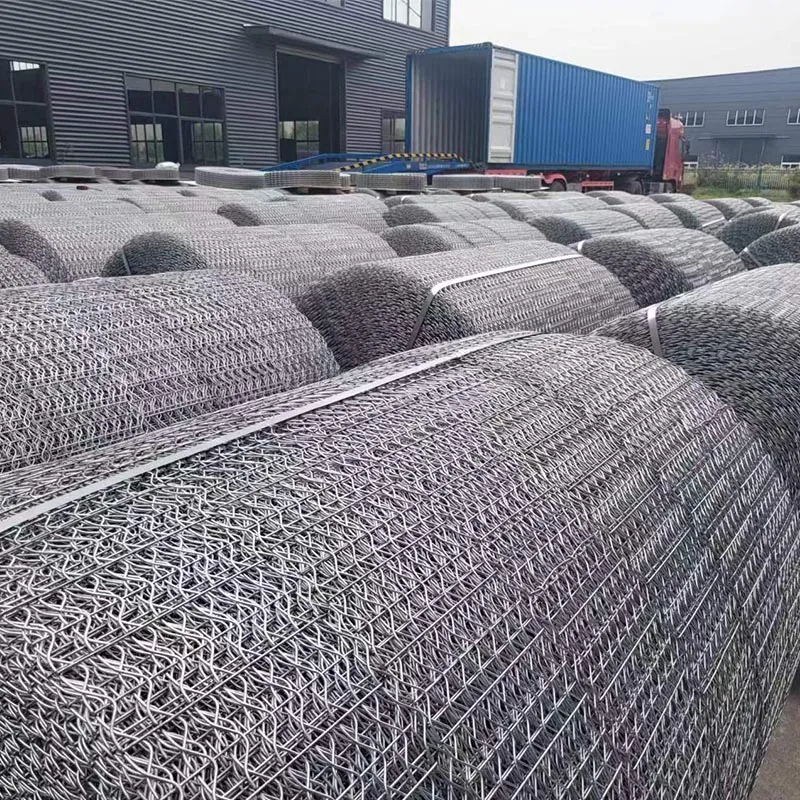

floor steel grating

Floor grating panels serve a vital role in numerous industrial and commercial applications, providing superior support, enhanced safety, and optimal drainage solutions. Expertly crafted, these panels are crucial for ensuring safety and functionality in settings that require durable flooring solutions. Understanding how floor grating panels work, their benefits, material composition, and installation processes is essential for industry professionals or anyone considering flooring upgrades.

Emphasis on Authoritativeness Companies that manufacture floor grating panels often lead their sectors through consistent innovation. An authoritative stance is maintained through rigorous testing and adherence to safety standards and load-bearing capacities. Leading manufacturers abide by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) guidelines, ensuring products meet prescribed safety and quality benchmarks. This authoritative commitment assures clients that they are investing in panels that not only meet but exceed industry standards. Furthermore, industry top players provide extensive guides and educational resources to help clientele understand product usability and benefits. This transparency fosters a knowledge-based trusting relationship with clients, underscoring their authoritative position in the market. Trustworthiness in Installation and Maintenance Efficient installation is crucial to ensure the longevity and functionality of floor grating panels. Trustworthy suppliers offer comprehensive installation services, with expertise in addressing site-specific challenges. Proper securement and alignment guarantee that panels are not only efficient in their current state but can withstand years of wear with minimal upkeep. Once installed, maintaining the integrity of these panels is straightforward, often requiring a simple cleaning to remove debris that could accumulate and affect drainage. The low maintenance aspect significantly adds to their cost-effectiveness, reducing the necessity for frequent replacements and repairs. Clients can trust in the longevity and sustained performance of their investment, backed by manufacturers' warranties that reflect confidence in their durability and longevity. In conclusion, floor grating panels symbolize an intersection of expert craftsmanship, authoritative quality, and end-user centered design principles. These structures serve more than just functional purposes; they are a testament to advanced engineering tailored to meet the specific needs of diverse industries. With a focus on safety, strength, and sustainability, floor grating panels remain an indispensable element in industrial flooring solutions, backed by the experience of users and experts globally.

Emphasis on Authoritativeness Companies that manufacture floor grating panels often lead their sectors through consistent innovation. An authoritative stance is maintained through rigorous testing and adherence to safety standards and load-bearing capacities. Leading manufacturers abide by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) guidelines, ensuring products meet prescribed safety and quality benchmarks. This authoritative commitment assures clients that they are investing in panels that not only meet but exceed industry standards. Furthermore, industry top players provide extensive guides and educational resources to help clientele understand product usability and benefits. This transparency fosters a knowledge-based trusting relationship with clients, underscoring their authoritative position in the market. Trustworthiness in Installation and Maintenance Efficient installation is crucial to ensure the longevity and functionality of floor grating panels. Trustworthy suppliers offer comprehensive installation services, with expertise in addressing site-specific challenges. Proper securement and alignment guarantee that panels are not only efficient in their current state but can withstand years of wear with minimal upkeep. Once installed, maintaining the integrity of these panels is straightforward, often requiring a simple cleaning to remove debris that could accumulate and affect drainage. The low maintenance aspect significantly adds to their cost-effectiveness, reducing the necessity for frequent replacements and repairs. Clients can trust in the longevity and sustained performance of their investment, backed by manufacturers' warranties that reflect confidence in their durability and longevity. In conclusion, floor grating panels symbolize an intersection of expert craftsmanship, authoritative quality, and end-user centered design principles. These structures serve more than just functional purposes; they are a testament to advanced engineering tailored to meet the specific needs of diverse industries. With a focus on safety, strength, and sustainability, floor grating panels remain an indispensable element in industrial flooring solutions, backed by the experience of users and experts globally.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024