- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 20, 2025 02:20

Back to list

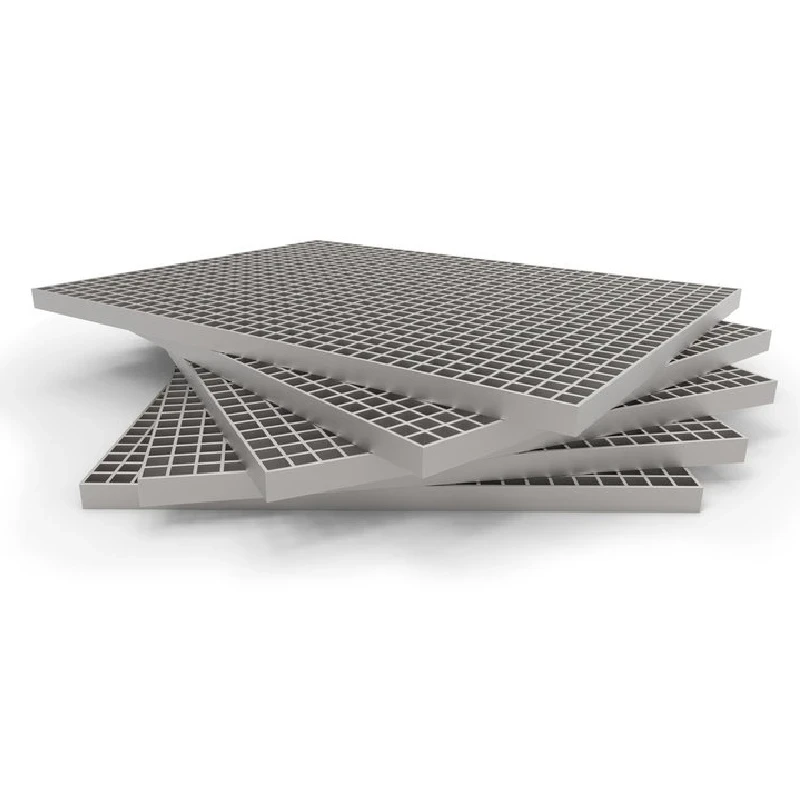

steel walkway grating

Steel galvanized grating is a remarkable innovation in the field of industrial flooring solutions, offering a blend of strength, durability, and corrosion resistance that is unparalleled. When utilized in the construction of floor forge walkways, its efficacy and benefits become evidently clear. This article delves into the intricacies of steel galvanized grating for walkways, illuminating the pivotal reasons why it should be the material of choice for professionals globally.

When it comes to installation, steel galvanized grating is both versatile and user-friendly. It can be sized and shaped according to specific requirements, facilitating custom applications across various industries. The product's lightweight nature simplifies the installation process, reducing labor costs and time. Furthermore, its adaptability means it can be effortlessly installed on existing structures without the need for extensive modification. The environmental benefits of opting for galvanized steel grating are also noteworthy. Galvanization extends the life of the steel, slowing down natural degradation and reducing the need for frequent replacements. This longevity contributes to sustainability efforts by minimizing resource consumption and waste generation. Moreover, steel is a recyclable material, ensuring that, at the end of its life cycle, it can be repurposed into new products without losing its intrinsic properties. In summary, steel galvanized grating is a supportive backbone for constructing durable, safe, and efficient floor forge walkways. Its combination of resilience against corrosion, robust strength, aesthetic appeal, and safety features makes it an unparalleled choice for industrial flooring solutions. It embodies a perfect balance between functionality and cost-effectiveness, ensuring that facilities can maintain high operational standards while adhering to budget constraints. Industry professionals favor steel galvanized grating for walkways due to its ease of installation, long-term cost savings, and minimal environmental impact. By integrating this product into industrial designs, businesses not only bolster their infrastructure but also enhance safety measures, contributing to a more secure and productive working environment. The decision to use steel galvanized grating is a testament to a commitment to quality, sustainability, and excellence in industrial construction projects.

When it comes to installation, steel galvanized grating is both versatile and user-friendly. It can be sized and shaped according to specific requirements, facilitating custom applications across various industries. The product's lightweight nature simplifies the installation process, reducing labor costs and time. Furthermore, its adaptability means it can be effortlessly installed on existing structures without the need for extensive modification. The environmental benefits of opting for galvanized steel grating are also noteworthy. Galvanization extends the life of the steel, slowing down natural degradation and reducing the need for frequent replacements. This longevity contributes to sustainability efforts by minimizing resource consumption and waste generation. Moreover, steel is a recyclable material, ensuring that, at the end of its life cycle, it can be repurposed into new products without losing its intrinsic properties. In summary, steel galvanized grating is a supportive backbone for constructing durable, safe, and efficient floor forge walkways. Its combination of resilience against corrosion, robust strength, aesthetic appeal, and safety features makes it an unparalleled choice for industrial flooring solutions. It embodies a perfect balance between functionality and cost-effectiveness, ensuring that facilities can maintain high operational standards while adhering to budget constraints. Industry professionals favor steel galvanized grating for walkways due to its ease of installation, long-term cost savings, and minimal environmental impact. By integrating this product into industrial designs, businesses not only bolster their infrastructure but also enhance safety measures, contributing to a more secure and productive working environment. The decision to use steel galvanized grating is a testament to a commitment to quality, sustainability, and excellence in industrial construction projects.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024