- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:56

Back to list

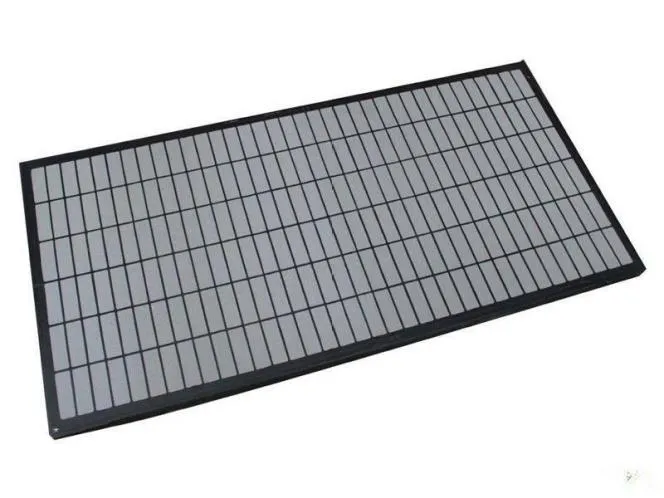

steel walkway grating

Navigating the Costs of Steel Grating Expert Insights for Your Next Project

Installation and Maintenance Installation conditions and maintenance requirements also impact the cost considerations of steel grating. Easy-to-install grating, designed for minimal labor, can reduce initial setup costs. Similarly, maintenance-intensive grating may accumulate expenses over time, affecting the long-term cost-effectiveness of the investment. It is vital to consider the lifecycle costs, ensuring the selected grating meets both budgetary constraints and operational needs. Supply Chain and Market Conditions The global steel market is subject to fluctuations, impacting the cost of raw materials. Supply chain dynamics, such as transportation costs and tariff rates, can also cause price variations. Geographic location, proximity to suppliers, and current market demand are factors that can either raise or lower costs. Staying informed about these market conditions helps in making cost-effective decisions and timing purchases to optimize savings. Choosing the Right Supplier Collaborating with reputable suppliers forms the cornerstone of an efficient steel grating procurement process. Trusted suppliers provide transparent pricing, high-quality products, and reliable customer service. Engaging with industry-certified suppliers who offer warranties and post-sale support further enhances the trustworthiness of your investment, ensuring peace of mind and product longevity. In conclusion, understanding the multifaceted aspects that determine the cost of steel grating equips you with the knowledge to make informed purchasing decisions. By considering the type, design, manufacturing process, installation, and market variables, along with choosing a reputable supplier, you can effectively navigate costs while ensuring quality and reliability for your projects.

Installation and Maintenance Installation conditions and maintenance requirements also impact the cost considerations of steel grating. Easy-to-install grating, designed for minimal labor, can reduce initial setup costs. Similarly, maintenance-intensive grating may accumulate expenses over time, affecting the long-term cost-effectiveness of the investment. It is vital to consider the lifecycle costs, ensuring the selected grating meets both budgetary constraints and operational needs. Supply Chain and Market Conditions The global steel market is subject to fluctuations, impacting the cost of raw materials. Supply chain dynamics, such as transportation costs and tariff rates, can also cause price variations. Geographic location, proximity to suppliers, and current market demand are factors that can either raise or lower costs. Staying informed about these market conditions helps in making cost-effective decisions and timing purchases to optimize savings. Choosing the Right Supplier Collaborating with reputable suppliers forms the cornerstone of an efficient steel grating procurement process. Trusted suppliers provide transparent pricing, high-quality products, and reliable customer service. Engaging with industry-certified suppliers who offer warranties and post-sale support further enhances the trustworthiness of your investment, ensuring peace of mind and product longevity. In conclusion, understanding the multifaceted aspects that determine the cost of steel grating equips you with the knowledge to make informed purchasing decisions. By considering the type, design, manufacturing process, installation, and market variables, along with choosing a reputable supplier, you can effectively navigate costs while ensuring quality and reliability for your projects.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024