- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 18:03

Back to list

Steel Grating

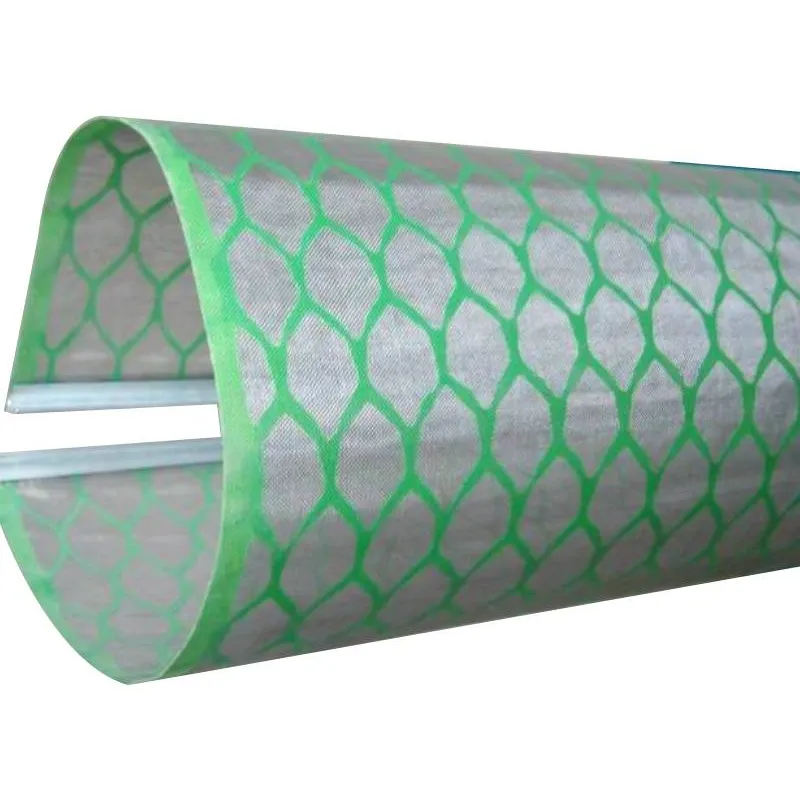

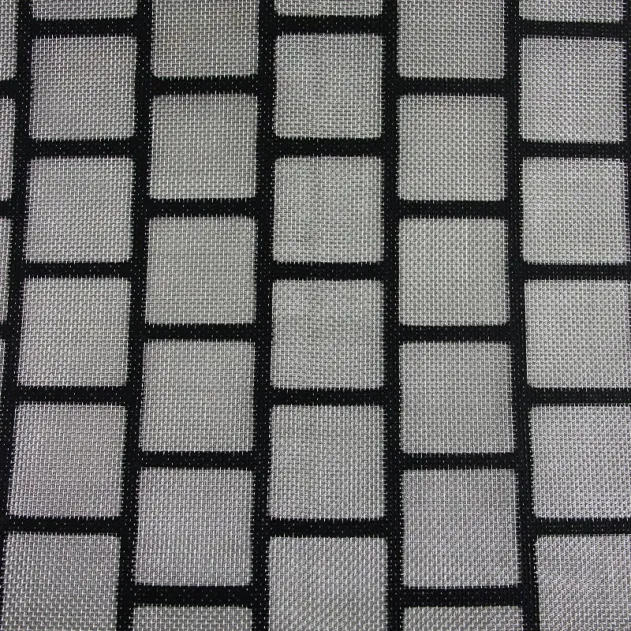

Unlocking the potential of close mesh grating involves understanding its comprehensive applications, robust advantages, and expert utilization across various industries. As a key component in numerous structural and safety applications, close mesh grating exemplifies superior design and functionality, making it a top choice among engineers and architects.

Trustworthiness emanates from the consistent performance of close mesh grating. Repeated success stories from various utilizations in industrial, commercial, and municipal projects build a strong testament to its reliability. The continued investment in research and development by manufacturing leaders also showcases a commitment to innovation, ensuring that close mesh grating remains at the forefront of engineering solutions with improved features and sustainable practices. In the realm of product selection, understanding these intricate details empowers stakeholders to make informed decisions. Close mesh grating is more than just a structural element; it is a comprehensive solution that embodies efficiency, safety, and innovation. For stakeholders considering enhancements to their project infrastructure, aligning their goals with the strengths of close mesh grating can result in long-term benefits that encompass economic efficiency, safety, and operational excellence. Businesses and project managers determined to leverage the maximum potential of close mesh grating must prioritize knowledge and expertise in their operational toolkit. By doing so, they harness not only the technical strengths but also bolster their reputation for safety and quality in an increasingly competitive market. In conclusion, close mesh grating is a forward-thinking investment in safety and durability. Through expert application and a profound understanding of its capacities and contributions, it stands as a pivotal asset within modern engineering and construction paradigms.

Trustworthiness emanates from the consistent performance of close mesh grating. Repeated success stories from various utilizations in industrial, commercial, and municipal projects build a strong testament to its reliability. The continued investment in research and development by manufacturing leaders also showcases a commitment to innovation, ensuring that close mesh grating remains at the forefront of engineering solutions with improved features and sustainable practices. In the realm of product selection, understanding these intricate details empowers stakeholders to make informed decisions. Close mesh grating is more than just a structural element; it is a comprehensive solution that embodies efficiency, safety, and innovation. For stakeholders considering enhancements to their project infrastructure, aligning their goals with the strengths of close mesh grating can result in long-term benefits that encompass economic efficiency, safety, and operational excellence. Businesses and project managers determined to leverage the maximum potential of close mesh grating must prioritize knowledge and expertise in their operational toolkit. By doing so, they harness not only the technical strengths but also bolster their reputation for safety and quality in an increasingly competitive market. In conclusion, close mesh grating is a forward-thinking investment in safety and durability. Through expert application and a profound understanding of its capacities and contributions, it stands as a pivotal asset within modern engineering and construction paradigms.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024