- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 18:26

Back to list

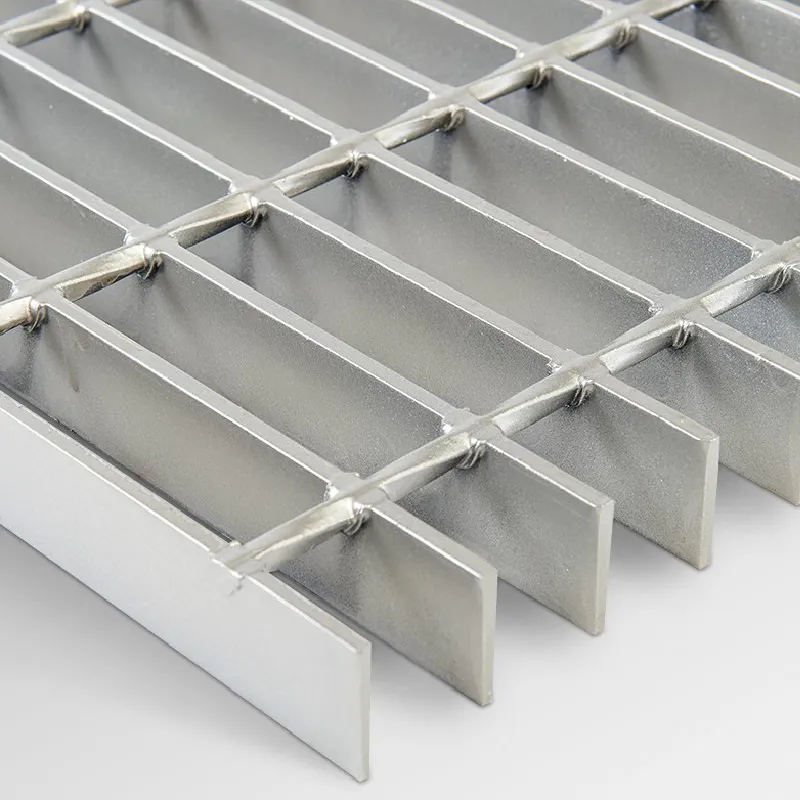

Welded Steel Grating

Bar grating, an essential component in various industrial and commercial applications, is often overlooked yet forms a critical part of structural design. Its inherent strength, durability, and versatility make it an unrivaled choice for constructing floors, walkways, mezzanines, and safety barriers. This article delves into the various aspects of bar grating, highlighting its significance and providing insights based on real-world experiences and expertise.

In terms of authoritativeness, regulatory compliance is a pivotal consideration. Bar grating must adhere to stringent standards set forth by national and international bodies to ensure safety and performance. These standards govern aspects like load bearing, slip resistance, and fire safety, which are critical in settings where human safety is paramount. Many experts document that compliance not only assures user safety but also enhances the credibility and reliability of the installation, an essential factor in project planning and execution. Trustworthiness in bar grating is also deeply connected with manufacturer reputation and warranties provided. Industry veterans advise selecting products from reputable manufacturers known for their quality assurance processes and after-sales support. A manufacturer’s commitment to quality is often reflected in their warranty policies, offering clients peace of mind regarding the longevity and performance of the product. Testimonials and case studies are valuable resources in assessing the trustworthiness of different grating solutions by providing insights into previous applications and customer satisfaction levels. Finally, the customization options available in bar grating design enhance its adaptability to bespoke project requirements. Whether it's varying bar profiles, spacing configurations, or surface finishes, the ability to tailor bar grating solutions provides designers and engineers with flexibility for seamless integration into diverse architectural plans. Many professionals share experiences where custom grating designs have solved unique structural challenges, underscoring the importance of collaboration between suppliers and clients to achieve optimal outcomes. In conclusion, bar grating is more than a mere structural element; it stands as a testament to engineering ingenuity. Real-world experience, coupled with technical expertise, highlights its indispensable role in creating safe and efficient environments. As industries strive for more sustainable and cost-effective solutions, bar grating continues to prove its worth, underpinned by authority and trust from both manufacturers and end-users alike. Unlocking its potential lies in informed decision-making, backed by accurate assessments and collaboration, ensuring that bar grating remains a cornerstone of modern infrastructure.

In terms of authoritativeness, regulatory compliance is a pivotal consideration. Bar grating must adhere to stringent standards set forth by national and international bodies to ensure safety and performance. These standards govern aspects like load bearing, slip resistance, and fire safety, which are critical in settings where human safety is paramount. Many experts document that compliance not only assures user safety but also enhances the credibility and reliability of the installation, an essential factor in project planning and execution. Trustworthiness in bar grating is also deeply connected with manufacturer reputation and warranties provided. Industry veterans advise selecting products from reputable manufacturers known for their quality assurance processes and after-sales support. A manufacturer’s commitment to quality is often reflected in their warranty policies, offering clients peace of mind regarding the longevity and performance of the product. Testimonials and case studies are valuable resources in assessing the trustworthiness of different grating solutions by providing insights into previous applications and customer satisfaction levels. Finally, the customization options available in bar grating design enhance its adaptability to bespoke project requirements. Whether it's varying bar profiles, spacing configurations, or surface finishes, the ability to tailor bar grating solutions provides designers and engineers with flexibility for seamless integration into diverse architectural plans. Many professionals share experiences where custom grating designs have solved unique structural challenges, underscoring the importance of collaboration between suppliers and clients to achieve optimal outcomes. In conclusion, bar grating is more than a mere structural element; it stands as a testament to engineering ingenuity. Real-world experience, coupled with technical expertise, highlights its indispensable role in creating safe and efficient environments. As industries strive for more sustainable and cost-effective solutions, bar grating continues to prove its worth, underpinned by authority and trust from both manufacturers and end-users alike. Unlocking its potential lies in informed decision-making, backed by accurate assessments and collaboration, ensuring that bar grating remains a cornerstone of modern infrastructure.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024