- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 15, 2025 09:18

Back to list

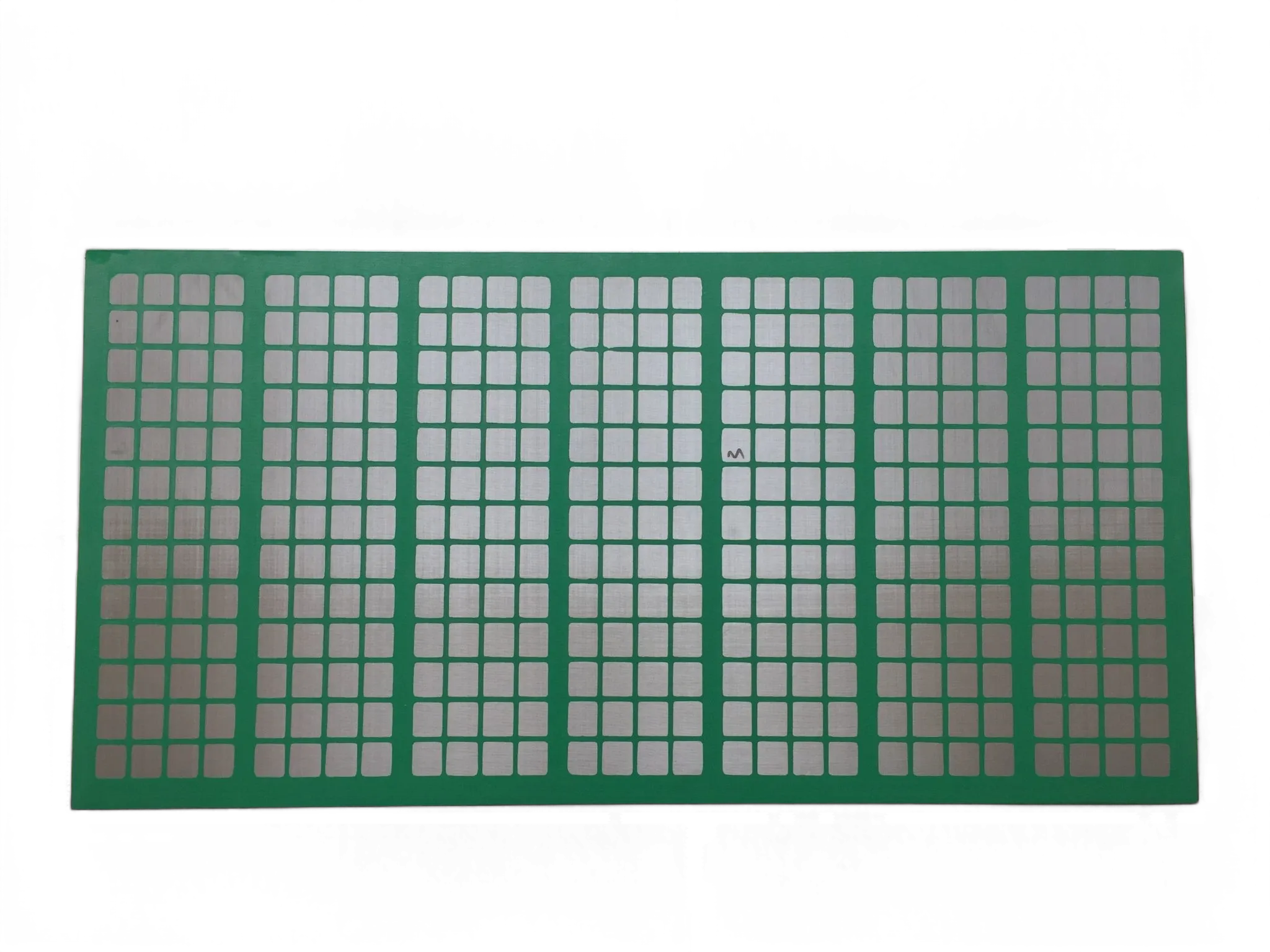

helideck perimeter net

Chain link helideck mesh represents a crucial innovation in the realm of safety and operational efficiency for offshore and onshore helipads. As the helicopter industry continues to grow, so does the demand for reliable and safe landing areas. This demand underscores the importance of using top-tier materials and designs, such as chain link helideck mesh, to ensure the highest safety standards.

Trustworthiness is a cornerstone of the chain link helideck mesh's reputation. Manufacturers adhere to stringent quality control procedures, tracing each phase from raw material acquisition to final installation. This transparency and commitment to quality reassure clients of the reliability of their installations. Furthermore, the mesh's non-invasive installation process ensures minimal disruption to ongoing operations, making it a preferred choice for operational continuity. In the competitive landscape of helipad safety solutions, chain link helideck mesh stands out due to its commitment to innovation, quality, and customer satisfaction. As operators and safety officers continue to prioritize safety and efficiency, the demand for chain link helideck mesh is poised to grow. Investing in this advanced material not only enhances safety but also optimizes operational efficacy by reducing downtime and maintenance costs. To sum up, chain link helideck mesh is not just a component of a helipad; it is a strategic investment in safety and operational excellence. Its proven performance across diverse environments, compliance with international safety standards, and user testimonials position it as an indispensable asset for modern helipad infrastructure. As technology and safety standards advance, chain link helideck mesh continues to lead the way, ensuring that helicopters, crews, and cargoes are safeguarded with the highest level of assurance.

Trustworthiness is a cornerstone of the chain link helideck mesh's reputation. Manufacturers adhere to stringent quality control procedures, tracing each phase from raw material acquisition to final installation. This transparency and commitment to quality reassure clients of the reliability of their installations. Furthermore, the mesh's non-invasive installation process ensures minimal disruption to ongoing operations, making it a preferred choice for operational continuity. In the competitive landscape of helipad safety solutions, chain link helideck mesh stands out due to its commitment to innovation, quality, and customer satisfaction. As operators and safety officers continue to prioritize safety and efficiency, the demand for chain link helideck mesh is poised to grow. Investing in this advanced material not only enhances safety but also optimizes operational efficacy by reducing downtime and maintenance costs. To sum up, chain link helideck mesh is not just a component of a helipad; it is a strategic investment in safety and operational excellence. Its proven performance across diverse environments, compliance with international safety standards, and user testimonials position it as an indispensable asset for modern helipad infrastructure. As technology and safety standards advance, chain link helideck mesh continues to lead the way, ensuring that helicopters, crews, and cargoes are safeguarded with the highest level of assurance.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024