- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 14:19

Back to list

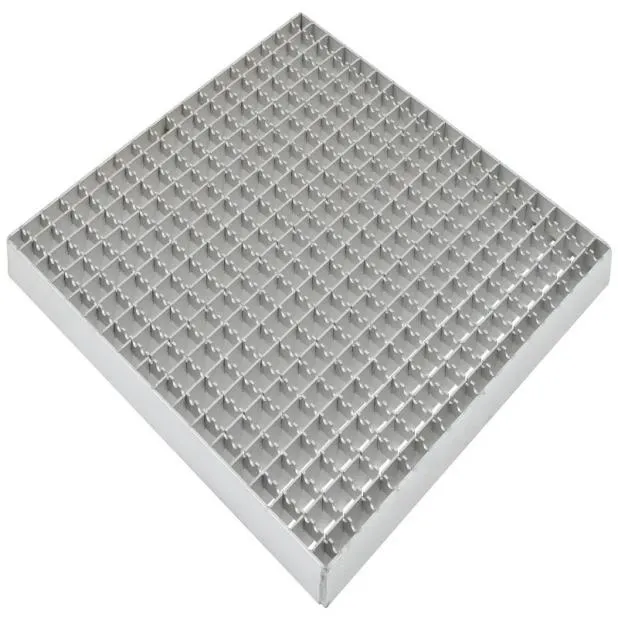

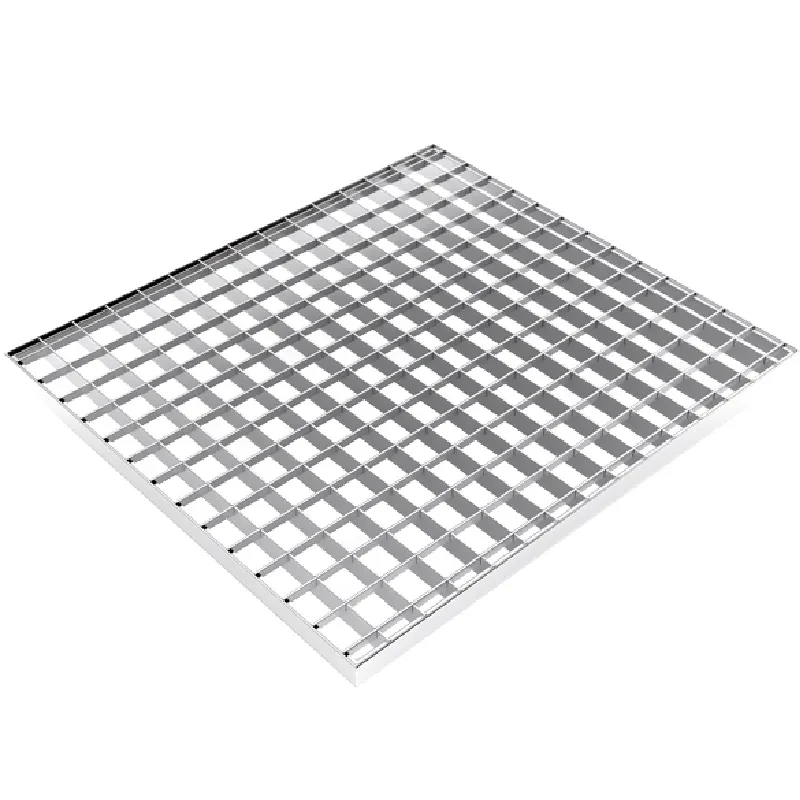

heavy-duty welded bar grating

Understanding bar grating weights is essential, not just for industry professionals but also for those seeking to incorporate these materials into various architectural and industrial projects. The focus on bar grating weights aligns closely with Experience, Expertise, Authoritativeness, and Trustworthiness (EEAT) principles, facilitating a comprehensive approach to choosing the right materials for your needs.

Further authoritativeness comes from adhering to industry standards and guidelines, such as those provided by the National Association of Architectural Metal Manufacturers (NAAMM) or the American National Standards Institute (ANSI). These standards dictate the minimum weight and strength requirements for different applications, ensuring safety and reliability. Engaging with certified suppliers and following these guidelines underscores the commitment to offering dependable and authoritative insights into bar grating weights. Trustworthiness in determining appropriate bar grating weights also stems from transparency in material specifications. A clear and honest breakdown of weight per square foot, load bearing capacity, and suitable applications helps build confidence in the decision-making process. Many experienced suppliers and manufacturers provide detailed catalogs highlighting these aspects, enabling well-informed choices tailored to the project's needs. Additionally, calculating bar grating weight involves precise methodologies, such as considering bar size, spacing, length, and width. These calculations often require specialized knowledge, with experts employing mathematical formulas or computer-aided design (CAD) software to estimate total weight accurately. This level of precision is imperative for predicting load handling capabilities and ensuring compliance with project specifications. Ultimately, a deeper insight into bar grating weights not only supports functional and economical material selection but also enhances the safety and durability of the structure where they are applied. By leveraging expert knowledge and adhering to industry standards, one can make informed decisions that encapsulate the essence of Experience, Expertise, Authoritativeness, and Trustworthiness. This approach ensures that every bar grating purchase aligns with the highest standards of quality and performance, delivering long-lasting value across diverse applications.

Further authoritativeness comes from adhering to industry standards and guidelines, such as those provided by the National Association of Architectural Metal Manufacturers (NAAMM) or the American National Standards Institute (ANSI). These standards dictate the minimum weight and strength requirements for different applications, ensuring safety and reliability. Engaging with certified suppliers and following these guidelines underscores the commitment to offering dependable and authoritative insights into bar grating weights. Trustworthiness in determining appropriate bar grating weights also stems from transparency in material specifications. A clear and honest breakdown of weight per square foot, load bearing capacity, and suitable applications helps build confidence in the decision-making process. Many experienced suppliers and manufacturers provide detailed catalogs highlighting these aspects, enabling well-informed choices tailored to the project's needs. Additionally, calculating bar grating weight involves precise methodologies, such as considering bar size, spacing, length, and width. These calculations often require specialized knowledge, with experts employing mathematical formulas or computer-aided design (CAD) software to estimate total weight accurately. This level of precision is imperative for predicting load handling capabilities and ensuring compliance with project specifications. Ultimately, a deeper insight into bar grating weights not only supports functional and economical material selection but also enhances the safety and durability of the structure where they are applied. By leveraging expert knowledge and adhering to industry standards, one can make informed decisions that encapsulate the essence of Experience, Expertise, Authoritativeness, and Trustworthiness. This approach ensures that every bar grating purchase aligns with the highest standards of quality and performance, delivering long-lasting value across diverse applications.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024