- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 04:23

Back to list

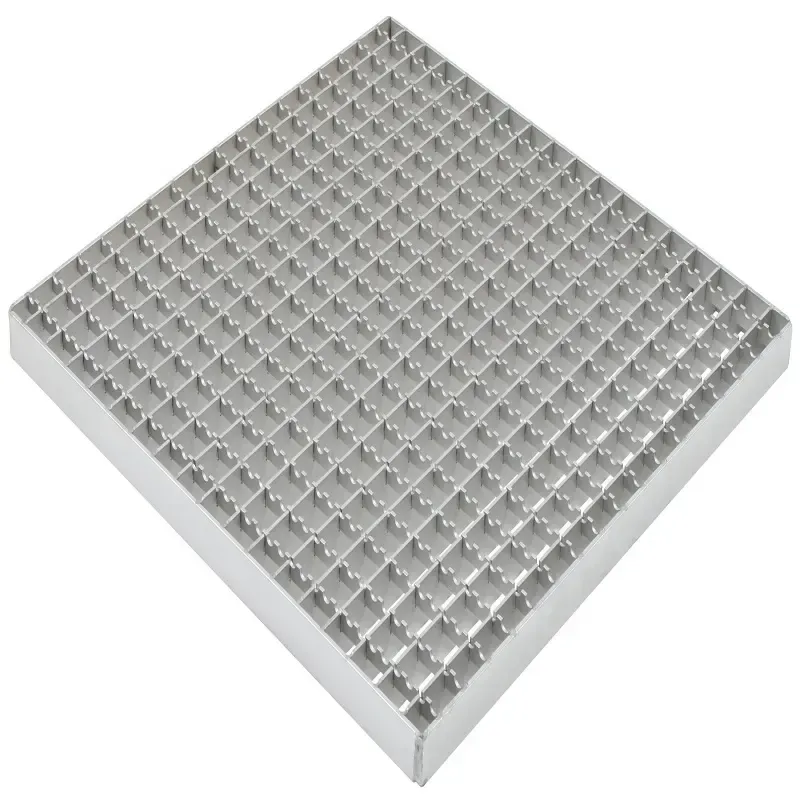

bar grating metal

Bar grating metal has become an indispensable component across a broad spectrum of industrial applications, offering unique benefits that set it apart from other materials. With its robust composition and versatile nature, bar grating steel becomes a reliable ally in creating floors, walkways, platforms, and stair treads in environments that demand high durability and safety.

The trustworthiness of bar grating stems from its proven track record and the confidence it instills in stakeholders. Supporting structures at heights or over considerable spans requires materials that do not compromise on quality. Leading manufacturers ensure that every batch of metal grating undergoes rigorous testing to meet both industry and in-house quality assurance protocols. Fabrication processes, including cutting, welding, and finishing, are optimized using cutting-edge technology to guarantee consistency and superior performance. Companies specializing in bar grating not only offer high-quality products but also provide extensive support services from custom fabrication to on-site consultation. Experienced professionals guide clients through the process of selection, customization, and installation, emphasizing the importance of product suitability and compliance. This concierge approach reinforces the reliability of bar grating solutions and cultivates long-term partnerships built on trust and successful outcomes. Innovation within the bar grating industry continues to evolve, with new designs and materials being developed to meet modern infrastructure demands. The integration of slip-resistant surfaces and enhanced design features makes it possible to use bar grating in environments previously considered challenging or unsafe. Sustainable alternatives are being explored as well, aligning industry practices with global environmental goals without compromising on the integral qualities that make metal grating a preferred choice. Bar grating's role in the industrial sector cannot be overstated. Its fundamental characteristics—resilience, adaptability, and high performance—form the backbone of numerous successful industrial operations worldwide. As technological advancements continue to push the boundaries of engineering capabilities, metal grating stands firm, evolving alongside to meet the demands of tomorrow’s challenges. Investing in high-quality bar grating not only ensures operational efficiency and safety but also affirms the commitment to infrastructure resilience, echoing the industry’s drive toward excellence and sustainability.

The trustworthiness of bar grating stems from its proven track record and the confidence it instills in stakeholders. Supporting structures at heights or over considerable spans requires materials that do not compromise on quality. Leading manufacturers ensure that every batch of metal grating undergoes rigorous testing to meet both industry and in-house quality assurance protocols. Fabrication processes, including cutting, welding, and finishing, are optimized using cutting-edge technology to guarantee consistency and superior performance. Companies specializing in bar grating not only offer high-quality products but also provide extensive support services from custom fabrication to on-site consultation. Experienced professionals guide clients through the process of selection, customization, and installation, emphasizing the importance of product suitability and compliance. This concierge approach reinforces the reliability of bar grating solutions and cultivates long-term partnerships built on trust and successful outcomes. Innovation within the bar grating industry continues to evolve, with new designs and materials being developed to meet modern infrastructure demands. The integration of slip-resistant surfaces and enhanced design features makes it possible to use bar grating in environments previously considered challenging or unsafe. Sustainable alternatives are being explored as well, aligning industry practices with global environmental goals without compromising on the integral qualities that make metal grating a preferred choice. Bar grating's role in the industrial sector cannot be overstated. Its fundamental characteristics—resilience, adaptability, and high performance—form the backbone of numerous successful industrial operations worldwide. As technological advancements continue to push the boundaries of engineering capabilities, metal grating stands firm, evolving alongside to meet the demands of tomorrow’s challenges. Investing in high-quality bar grating not only ensures operational efficiency and safety but also affirms the commitment to infrastructure resilience, echoing the industry’s drive toward excellence and sustainability.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024