- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 04:06

Back to list

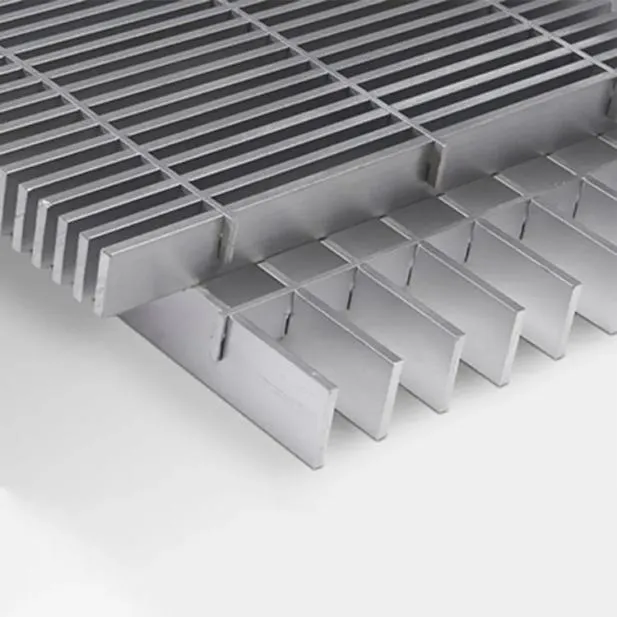

bar grating cost

Understanding the true cost of bar grating is essential for anyone involved in industrial, commercial, or even residential infrastructure projects. Many factors impact pricing, and by examining these, you not only make more informed purchasing decisions but also ensure the longevity and effectiveness of your projects.

Additional factors such as finishing and coating should not be overlooked. Galvanization, a common protective measure against corrosion, might add to the upfront cost but saves potential long-term expenses by extending the life of the grating. Other coatings, like powder coating, can offer not only protection but also aesthetic qualities, making bar grating suitable for areas frequented by the public. Logistics further influence the total expenditure. Shipping heavy materials like steel can be costly and is frequently dependent on distance, weight, and the current fuel market. Ensuring that your supplier can effectively meet your logistical needs within timelines and budget is crucial. Additionally, local regulations that dictate safety standards and specific requirements can also lead to additional costs during procurement and post-installation inspection phases. In order to navigate the intricate cost landscape of bar grating efficiently, partnering with an experienced supplier can be invaluable. With industry expertise and a keen understanding of market trends, specialized suppliers offer insights into cost-saving alternatives and provide guidance tailored to specific project requirements. They can provide custom solutions that optimize both functionality and budget, ensuring that you meet regulatory criteria without exceeding financial plans. Furthermore, investing in high-quality materials and proven manufacturing processes often translates to enhanced project performance and longevity. Such informed decision-making builds trust with stakeholders, demonstrating both competence and accountability in resource management and quality assurance. Ultimately, transparency in communication remains fundamental. Engaging with suppliers to obtain detailed breakdowns of costs, understanding the implications of each material choice and manufacturing option, and being aware of external factors such as market trends and regulations, prepares you to make sound, strategic decisions. By prioritizing both elements of cost-effectiveness and quality assurance, the procurement of bar grating transcends mere transactions, evolving into a pivotal aspect of structural integrity and project success.

Additional factors such as finishing and coating should not be overlooked. Galvanization, a common protective measure against corrosion, might add to the upfront cost but saves potential long-term expenses by extending the life of the grating. Other coatings, like powder coating, can offer not only protection but also aesthetic qualities, making bar grating suitable for areas frequented by the public. Logistics further influence the total expenditure. Shipping heavy materials like steel can be costly and is frequently dependent on distance, weight, and the current fuel market. Ensuring that your supplier can effectively meet your logistical needs within timelines and budget is crucial. Additionally, local regulations that dictate safety standards and specific requirements can also lead to additional costs during procurement and post-installation inspection phases. In order to navigate the intricate cost landscape of bar grating efficiently, partnering with an experienced supplier can be invaluable. With industry expertise and a keen understanding of market trends, specialized suppliers offer insights into cost-saving alternatives and provide guidance tailored to specific project requirements. They can provide custom solutions that optimize both functionality and budget, ensuring that you meet regulatory criteria without exceeding financial plans. Furthermore, investing in high-quality materials and proven manufacturing processes often translates to enhanced project performance and longevity. Such informed decision-making builds trust with stakeholders, demonstrating both competence and accountability in resource management and quality assurance. Ultimately, transparency in communication remains fundamental. Engaging with suppliers to obtain detailed breakdowns of costs, understanding the implications of each material choice and manufacturing option, and being aware of external factors such as market trends and regulations, prepares you to make sound, strategic decisions. By prioritizing both elements of cost-effectiveness and quality assurance, the procurement of bar grating transcends mere transactions, evolving into a pivotal aspect of structural integrity and project success.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024