- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 26, 2025 02:18

Back to list

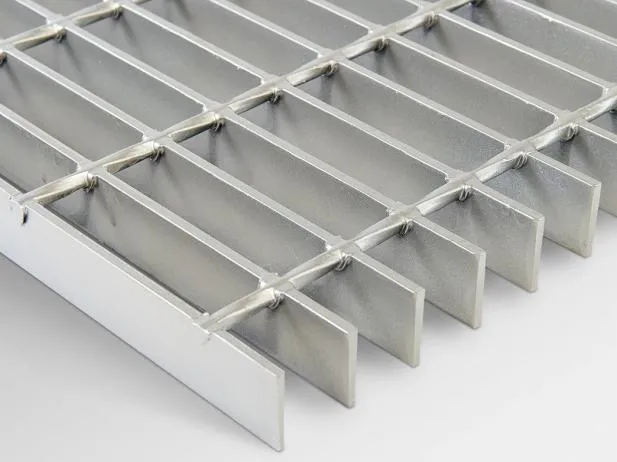

Steel Grating

Aluminum grating has emerged as a core component in diverse industrial applications, ranging from civil construction to mechanical engineering. Understanding the specifications of aluminum grating can enhance both its performance and utility in such fields. This comprehensive guide delivers insights grounded in extensive experience, detailed expertise, and authoritative knowledge to ensure trustworthy usage of aluminum grating.

The span of the grating, which refers to the distance between supports, plays a significant role in its application. Engineers often require precise calculations based on the grating's application—whether it’s for a small-scale installation like HVAC duct covers or larger industrial purposes like trench covers. Custom span designs can be achieved by varying bar thickness and depth, demonstrating the versatility of aluminum grating. Aluminum grade is another crucial specification that impacts the grating's performance. Commonly used grades like 6061-T6 and 6063-T6 offer a blend of tensile strength, toughness, and excellent corrosion resistance. The choice between these grades is typically aligned with the environmental conditions and the specific structural demands of the application site. For instance, 6061-T6 is prized for structural applications involving high stress, whereas 6063-T6 is preferred for decorative or architectural uses due to its superior surface finish. When considering aluminum grating, attention must be paid to finishes that further augment durability and aesthetic appeal. Options such as anodizing, powder coating, or painting can provide additional protection against corrosive environments and prolong the life of the grating. Anodization, in particular, offers an array of color choices alongside enhanced corrosion resistance, making it a preferred choice in external installations. Finally, the dimensional specifications like panel size, width, and thickness are critical for planning and installation. Expert installation teams understand that custom fabrication may be necessary to meet unique project requirements, promoting efficiency and functionality. Employing aluminum grating in infrastructure design necessitates a careful analysis of these specifications to maximize both safety and efficacy. When chosen thoughtfully, aluminum grating not only addresses functional needs but also contributes to sustainable practices due to the recyclability of aluminum. This sustainable aspect ensures that projects align with modern environmental standards, enhancing both the corporate responsibility and credibility of companies utilizing this versatile material. By leveraging this in-depth guide on aluminum grating specifications, professionals can make informed decisions that marry practical experience with rigorous technical standards, fostering projects that stand the test of time.

The span of the grating, which refers to the distance between supports, plays a significant role in its application. Engineers often require precise calculations based on the grating's application—whether it’s for a small-scale installation like HVAC duct covers or larger industrial purposes like trench covers. Custom span designs can be achieved by varying bar thickness and depth, demonstrating the versatility of aluminum grating. Aluminum grade is another crucial specification that impacts the grating's performance. Commonly used grades like 6061-T6 and 6063-T6 offer a blend of tensile strength, toughness, and excellent corrosion resistance. The choice between these grades is typically aligned with the environmental conditions and the specific structural demands of the application site. For instance, 6061-T6 is prized for structural applications involving high stress, whereas 6063-T6 is preferred for decorative or architectural uses due to its superior surface finish. When considering aluminum grating, attention must be paid to finishes that further augment durability and aesthetic appeal. Options such as anodizing, powder coating, or painting can provide additional protection against corrosive environments and prolong the life of the grating. Anodization, in particular, offers an array of color choices alongside enhanced corrosion resistance, making it a preferred choice in external installations. Finally, the dimensional specifications like panel size, width, and thickness are critical for planning and installation. Expert installation teams understand that custom fabrication may be necessary to meet unique project requirements, promoting efficiency and functionality. Employing aluminum grating in infrastructure design necessitates a careful analysis of these specifications to maximize both safety and efficacy. When chosen thoughtfully, aluminum grating not only addresses functional needs but also contributes to sustainable practices due to the recyclability of aluminum. This sustainable aspect ensures that projects align with modern environmental standards, enhancing both the corporate responsibility and credibility of companies utilizing this versatile material. By leveraging this in-depth guide on aluminum grating specifications, professionals can make informed decisions that marry practical experience with rigorous technical standards, fostering projects that stand the test of time.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024