- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 06, 2025 17:31

Back to list

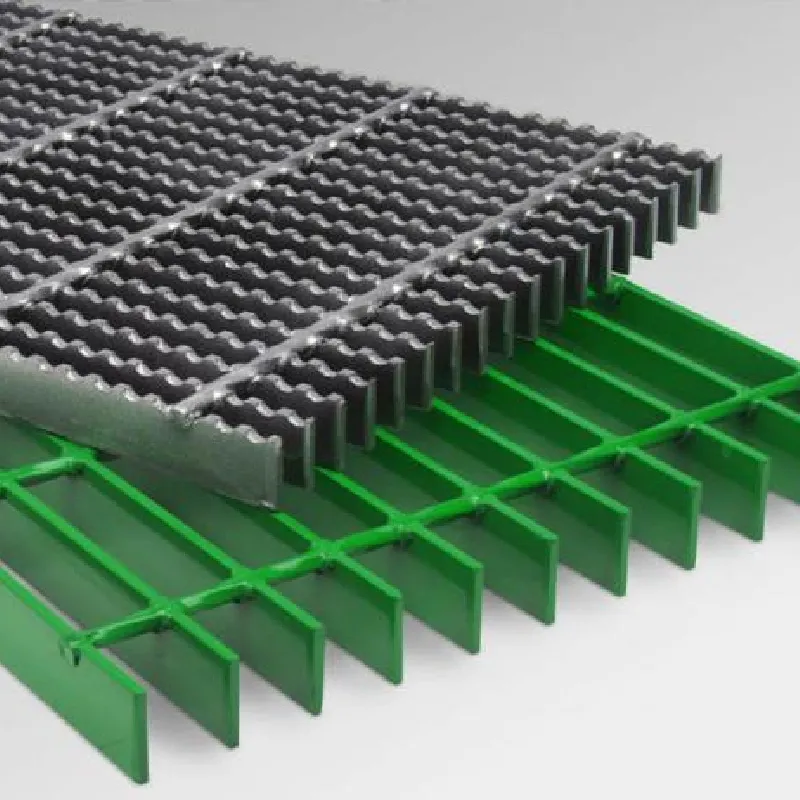

Steel Grating

Steel grating is an essential component in numerous industrial and commercial applications due to its strength, durability, and versatility. Understanding the various sizes in which steel grating is available can empower decision-makers to select the most appropriate type for their specific needs, maximizing both cost-effectiveness and functionality.

Furthermore, material thickness isn't the sole determinant of steel grating’s robustness. The finish of the grating—whether it's plain steel, galvanized, or stainless—affects both durability and visual appearance. Galvanized steel grating, for instance, provides enhanced resistance to corrosion, making it ideal for outdoor applications or environments exposed to moisture and chemicals. Stainless steel options offer a polished finish and are highly sought after in food processing or any sector where hygiene and aesthetics are paramount. Installation and safety standards are also significant when discussing steel grating size. When selecting a size, compliance with industry standards such as those set forth by the National Association of Architectural Metal Manufacturers (NAAMM) or the American National Standards Institute (ANSI) is crucial to ensure safety and reliability. These standards typically dictate the maximum allowable deflection under load, ensuring adequate performance in all circumstances. In conclusion, steel grating sizes encompass a variety of dimensions and configurations, each crafted with specific applications in mind. From bearing bar thickness to panel length, every element can be tailored to optimize strength, safety, and suitability for the task at hand. By approaching the selection process with detailed knowledge and a comprehensive understanding of industry standards, businesses can select grating that not only meets their needs but also provides enduring performance and value. Whether for an industrial catwalk, a public footbridge, or a secure flooring solution, the correct size and type of steel grating play a pivotal role in the success of each project.

Furthermore, material thickness isn't the sole determinant of steel grating’s robustness. The finish of the grating—whether it's plain steel, galvanized, or stainless—affects both durability and visual appearance. Galvanized steel grating, for instance, provides enhanced resistance to corrosion, making it ideal for outdoor applications or environments exposed to moisture and chemicals. Stainless steel options offer a polished finish and are highly sought after in food processing or any sector where hygiene and aesthetics are paramount. Installation and safety standards are also significant when discussing steel grating size. When selecting a size, compliance with industry standards such as those set forth by the National Association of Architectural Metal Manufacturers (NAAMM) or the American National Standards Institute (ANSI) is crucial to ensure safety and reliability. These standards typically dictate the maximum allowable deflection under load, ensuring adequate performance in all circumstances. In conclusion, steel grating sizes encompass a variety of dimensions and configurations, each crafted with specific applications in mind. From bearing bar thickness to panel length, every element can be tailored to optimize strength, safety, and suitability for the task at hand. By approaching the selection process with detailed knowledge and a comprehensive understanding of industry standards, businesses can select grating that not only meets their needs but also provides enduring performance and value. Whether for an industrial catwalk, a public footbridge, or a secure flooring solution, the correct size and type of steel grating play a pivotal role in the success of each project.

Share

Prev:

Next:

Latest news

-

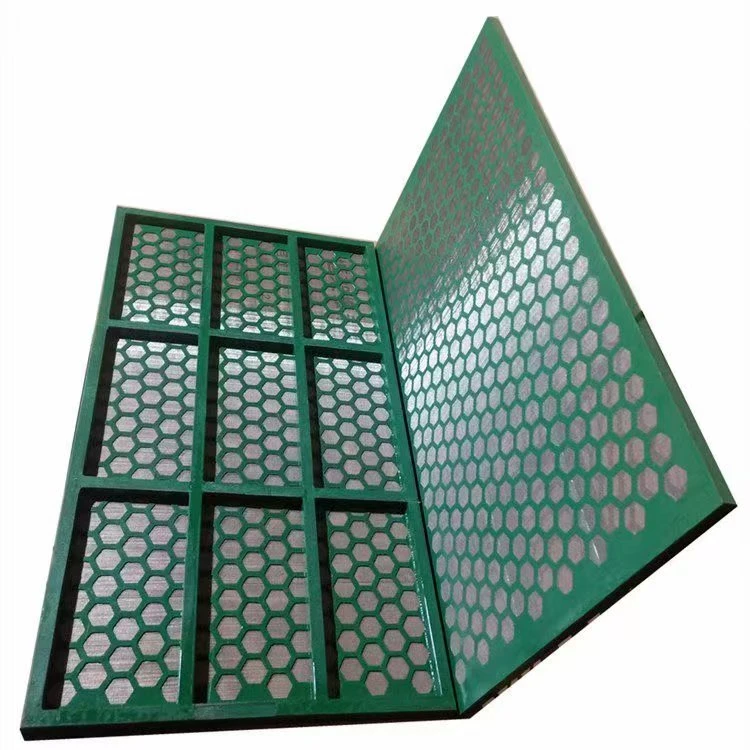

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024