- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 16:42

Back to list

what size does steel grating come in

When considering construction materials, steel grating stands out for its robustness, versatility, and practical applications in numerous industries. However, one vital consideration when selecting steel grating is understanding the available sizes and how they impact usage. This exploration of steel grating sizes is grounded in hands-on experience and extensive expertise, providing authoritative and trustworthy guidance for selecting just the right size for any project.

Equally important are ADA compliance considerations, particularly for pedestrian walkways. ADA guidelines dictate maximum spacing dimensions for lines and spacing to prevent the risk of accidents for persons with disabilities. Such guidelines influence both the size and type of grating chosen for public areas or any area where there is regular pedestrian traffic. One often overlooked, but critical consideration is the thickness of the steel used in the grating. The thickness generally ranges from 1/8 inch to 1/4 inch, depending on the material’s intended purpose. Heavier-duty gratings are typically thicker, offering higher resistance to bending and increased longevity. For high-impact industrial areas, thicker steel grating ensures durability and safety, while lighter opt for areas with less stringent requirements. Customization is another essential factor to consider with steel grating sizes. Manufacturers provide an array of customizable options tailored to meet specific project requirements, which might include unusually shaped spaces or specific load-bearing requirements. Customization adds a layer of complexity to manufacturing processes but ensures the steel grating is perfectly suited to any project, no matter how unique. In conclusion, selecting the correct size of steel grating involves a detailed understanding of specific application needs, safety regulations, and site conditions. By carefully considering these factors, it is possible to choose steel grating that not only fits the project parameters perfectly but also guarantees safety and durability for its intended application. Whether in industrial settings or public spaces, the right steel grating size plays a crucial role in ensuring the success and efficiency of a project.

Equally important are ADA compliance considerations, particularly for pedestrian walkways. ADA guidelines dictate maximum spacing dimensions for lines and spacing to prevent the risk of accidents for persons with disabilities. Such guidelines influence both the size and type of grating chosen for public areas or any area where there is regular pedestrian traffic. One often overlooked, but critical consideration is the thickness of the steel used in the grating. The thickness generally ranges from 1/8 inch to 1/4 inch, depending on the material’s intended purpose. Heavier-duty gratings are typically thicker, offering higher resistance to bending and increased longevity. For high-impact industrial areas, thicker steel grating ensures durability and safety, while lighter opt for areas with less stringent requirements. Customization is another essential factor to consider with steel grating sizes. Manufacturers provide an array of customizable options tailored to meet specific project requirements, which might include unusually shaped spaces or specific load-bearing requirements. Customization adds a layer of complexity to manufacturing processes but ensures the steel grating is perfectly suited to any project, no matter how unique. In conclusion, selecting the correct size of steel grating involves a detailed understanding of specific application needs, safety regulations, and site conditions. By carefully considering these factors, it is possible to choose steel grating that not only fits the project parameters perfectly but also guarantees safety and durability for its intended application. Whether in industrial settings or public spaces, the right steel grating size plays a crucial role in ensuring the success and efficiency of a project.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

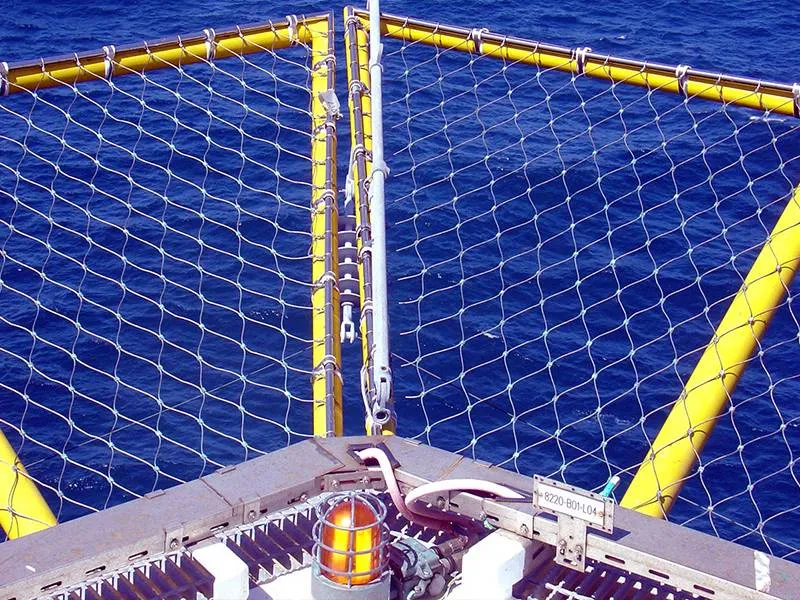

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024