- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 07, 2025 01:15

Back to list

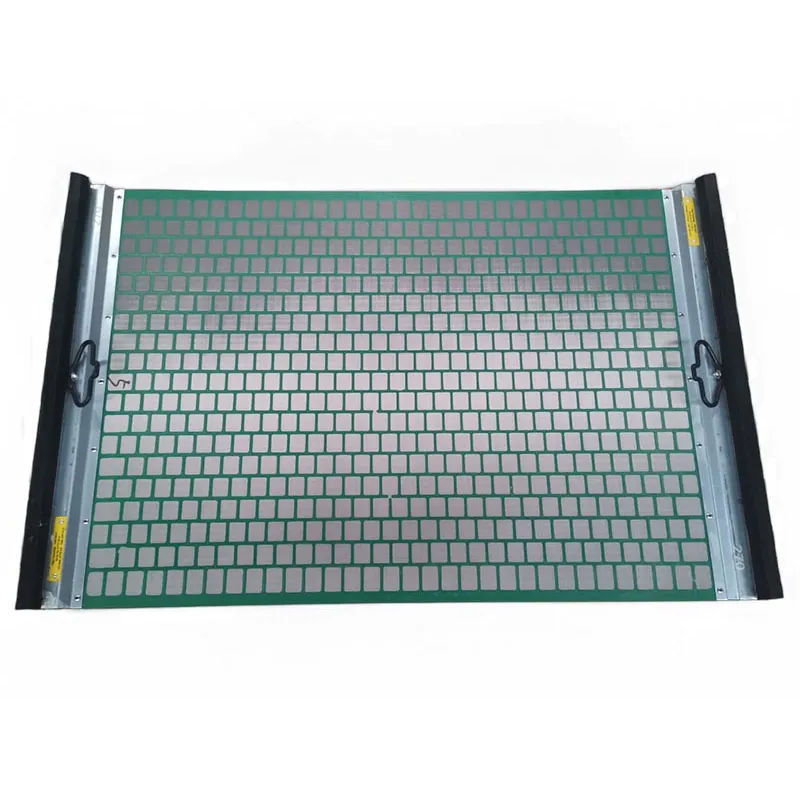

what is steel grating

Steel grating is an essential component in modern industrial applications, infrastructure, and architecture, valuing factors such as durability, versatility, and weight-bearing capabilities. Its unique open-grid design enables functionality ranging from flooring to creating walkways, making it indispensable in various industries. With an increasing need for materials that are reliable and robust, understanding steel grating's applications, benefits, types, and maintenance is crucial for industries looking to integrate high-performing products into their projects.

Beyond its inherent physical characteristics, steel grating is also highly customizable. It can be tailored to meet specific project needs, including special coatings for increased corrosion resistance or anti-slip finishes for enhanced safety. Custom fabrications such as stair treads and trench covers can be manufactured to exact specifications, ensuring that each application is as functional as it is efficient. These capabilities not only broaden the scope of where steel grating can be used but also enhance its adaptability to emerging technological and architectural trends. Despite its rugged design, steel grating requires regular maintenance to preserve its performance and longevity. Inspecting grating for signs of wear and corrosion is essential, especially in environments where it is exposed to harsh chemicals and weather conditions. Routine cleaning prevents the buildup of materials that can compromise its effectiveness, and timely replacement of any damaged sections can prevent potential safety hazards. Implementing a comprehensive maintenance schedule ensures that steel grating continues to perform optimally over the long term. For industries seeking a reliable, versatile, and cost-effective material for a wide range of applications, steel grating presents an unmatched solution. Its adaptability, strength, and ease of installation position it as a staple material across multiple sectors. By investing in quality steel grating and implementing proper maintenance measures, industries can enhance both operational efficiency and safety, reaffirming the material's authority as a backbone of modern industrial infrastructure. Understanding these elements further solidifies steel grating not just as a material choice, but as a strategic asset in industrial and architectural design.

Beyond its inherent physical characteristics, steel grating is also highly customizable. It can be tailored to meet specific project needs, including special coatings for increased corrosion resistance or anti-slip finishes for enhanced safety. Custom fabrications such as stair treads and trench covers can be manufactured to exact specifications, ensuring that each application is as functional as it is efficient. These capabilities not only broaden the scope of where steel grating can be used but also enhance its adaptability to emerging technological and architectural trends. Despite its rugged design, steel grating requires regular maintenance to preserve its performance and longevity. Inspecting grating for signs of wear and corrosion is essential, especially in environments where it is exposed to harsh chemicals and weather conditions. Routine cleaning prevents the buildup of materials that can compromise its effectiveness, and timely replacement of any damaged sections can prevent potential safety hazards. Implementing a comprehensive maintenance schedule ensures that steel grating continues to perform optimally over the long term. For industries seeking a reliable, versatile, and cost-effective material for a wide range of applications, steel grating presents an unmatched solution. Its adaptability, strength, and ease of installation position it as a staple material across multiple sectors. By investing in quality steel grating and implementing proper maintenance measures, industries can enhance both operational efficiency and safety, reaffirming the material's authority as a backbone of modern industrial infrastructure. Understanding these elements further solidifies steel grating not just as a material choice, but as a strategic asset in industrial and architectural design.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024